Skirting board pre-installation equipment

A pre-installation and footing technology, which is applied in the direction of construction and building construction, can solve the problems of expensive floor, time-consuming and labor-intensive installation of the floor, and unsatisfactory floor installation effect, so as to improve the effect and save installation The effect of time and installation manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

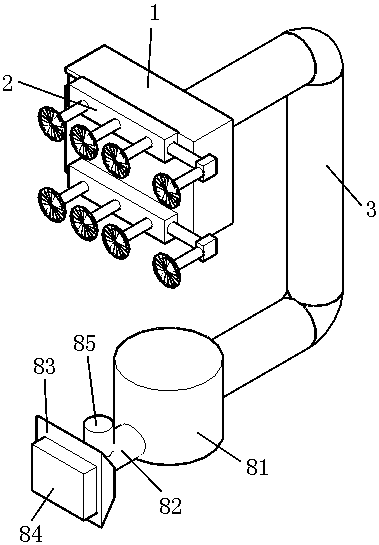

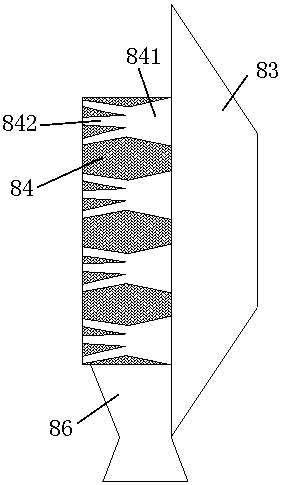

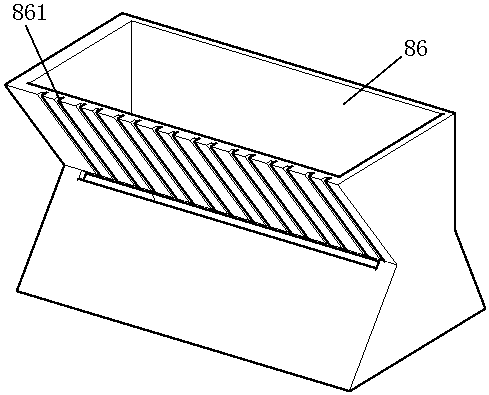

[0027] Such as Figures 1 to 3 As shown, a base line pre-installation equipment includes a fuselage 1, a controller and power equipment arranged inside the fuselage 1, a moving mechanism 2 connected to one side of the fuselage 1, and a The position adjustment mechanism 3 connected to the other opposite side of the body 1, and the wall glue brushing mechanism connected with the position adjustment mechanism 3, the moving mechanism 2, the position adjustment mechanism 3 and the wall glue brush mechanism are all Electrically connected with the controller. The base line pre-installation equipment also includes a remote controller wirelessly connected to the controller, and the staff can control the base line pre-installation equipment through the remote control to brush the wall near the ground with gl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap