Lift limiter for compressor

A lift limiter and compressor technology, applied in the field of lift limiters, can solve the problems of reduced service life of exhaust valve plates, reduced compressor efficiency, large contact stress, etc., and can reduce impact and vibration. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

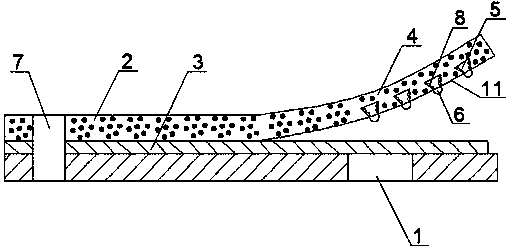

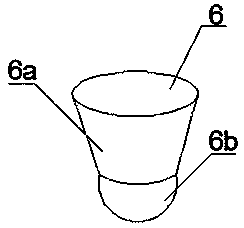

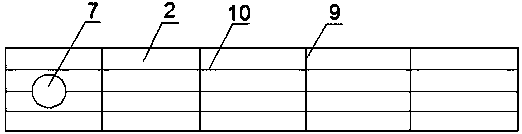

[0015] like Figure 1 ~ Figure 3 As shown in the structural diagram of the present invention, a lift limiter for a compressor includes a lift limiter body 2 arranged on the exhaust hole 1 of the compressor, and the lift limiter An exhaust valve plate 3 is provided between the body 2 and the exhaust hole 1; one end of the lift limiter body 2 is set as an upwardly tilted part 4, and the upward lift of the lift limiter body 2 At least one groove 5 is evenly provided on the lower surface of the raised part 4; the groove 5 is a rounded truncated groove; the groove 5 is provided with a shock absorber 6; the shock absorber 6 is at least one; There is a gap 11 between the shock absorbers 6; the shock absorber 6 is integrally formed by rounded table structure 6a and hemispherical structure 6b; the shock absorber 6 is made of elastic material;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com