Hydraulic nut for reactor pressure vessel

A technology for hydraulic nuts and pressure vessels, which is applied in the direction of nuts, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problems of high time cost, high manufacturing and operation and maintenance costs, and achieve reliability and simplification. The effect of tightening and dismantling the process and shortening the time occupied by the critical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

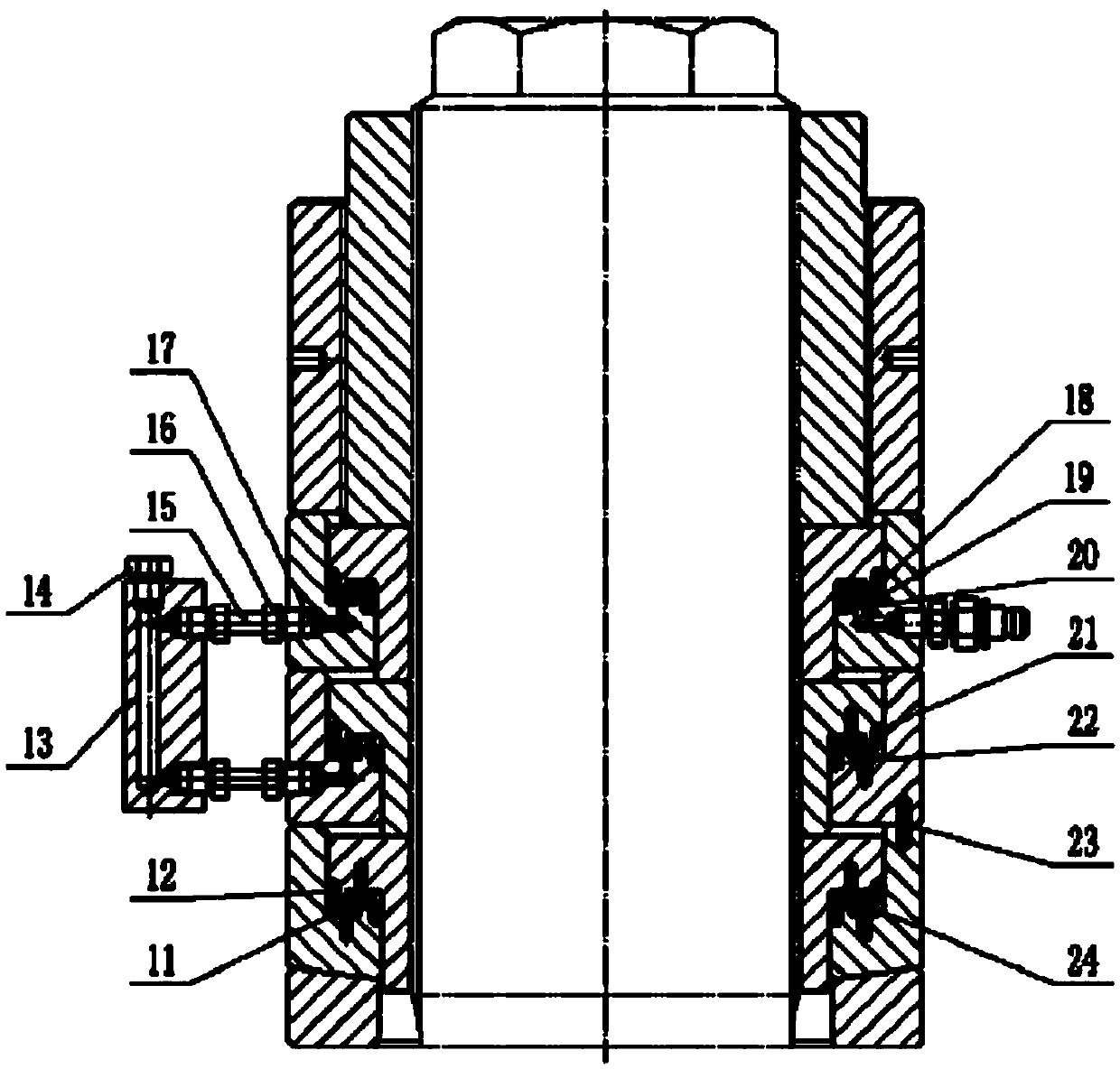

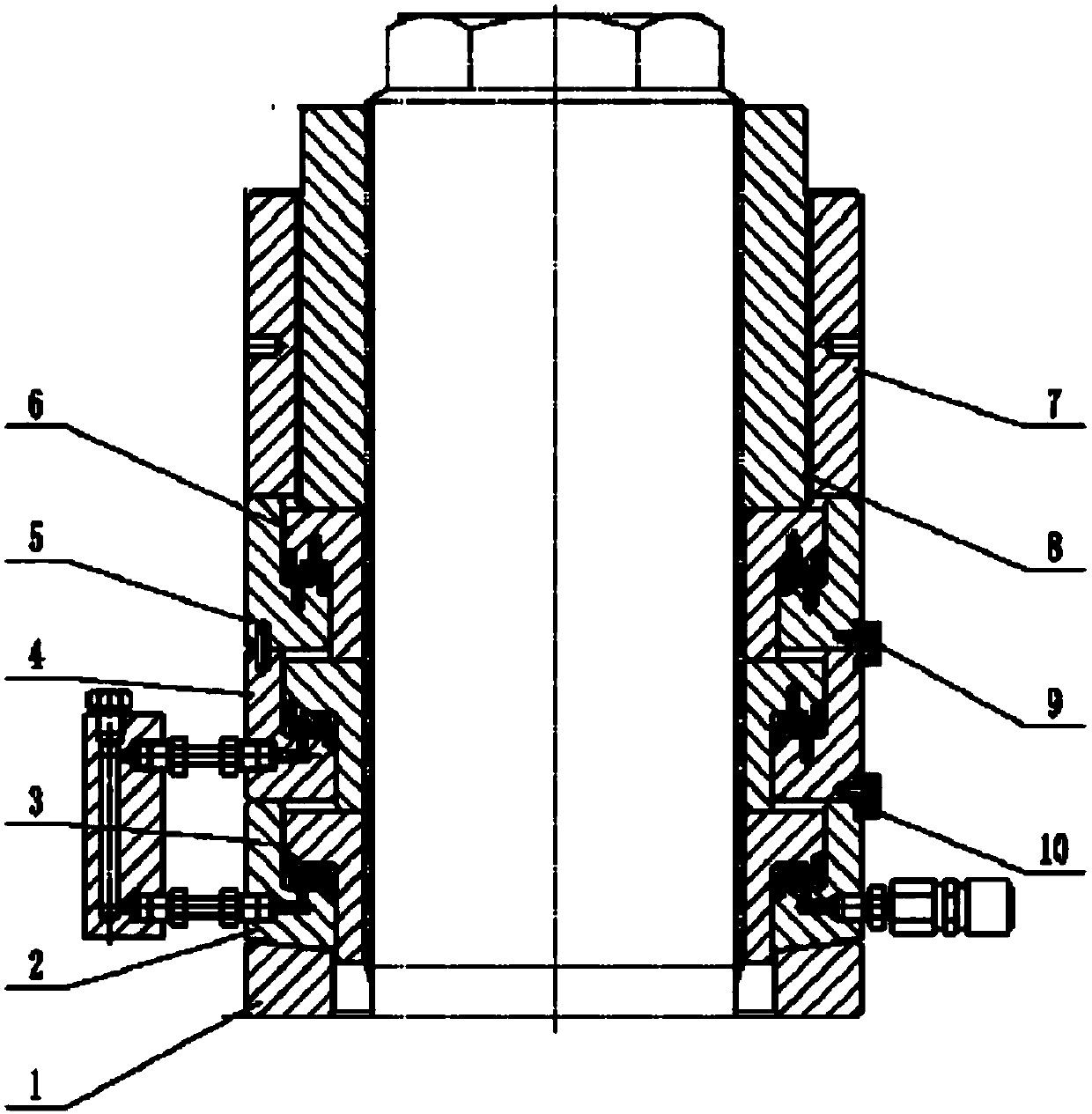

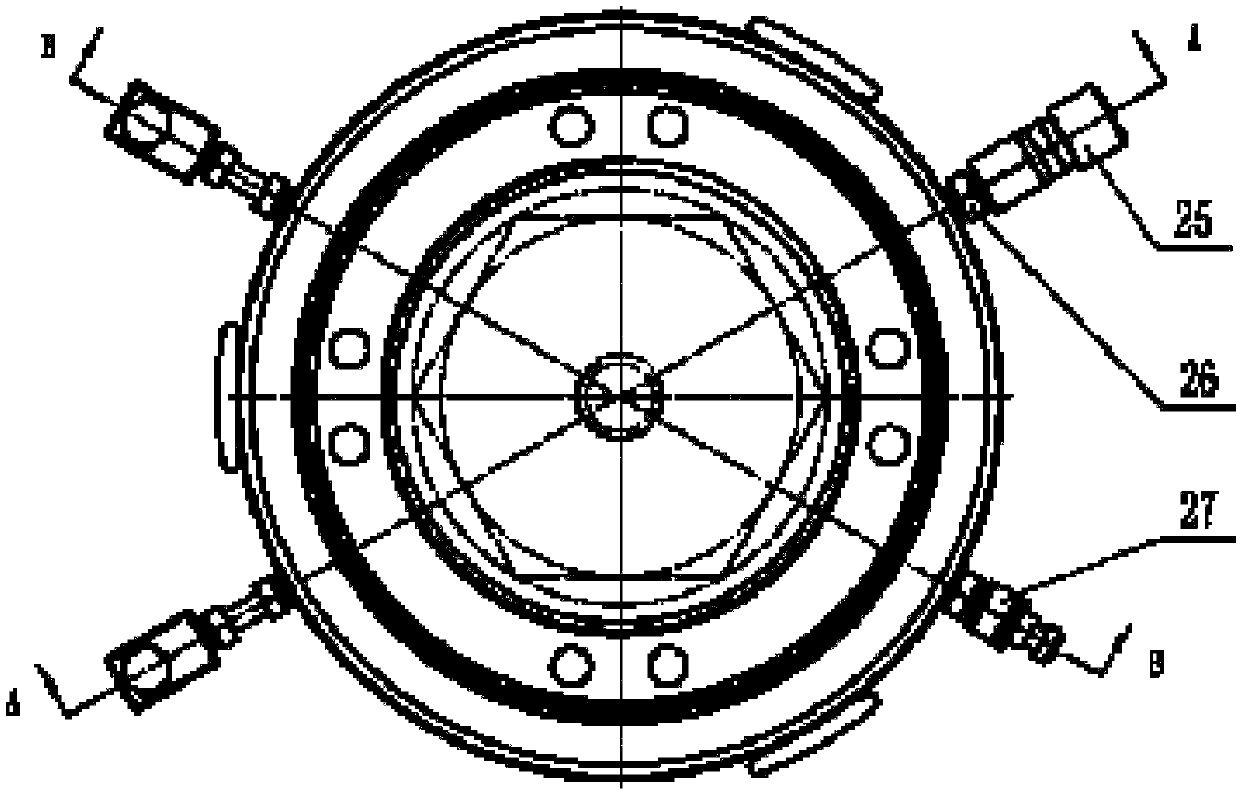

[0017] Such as Figure 1-3 As shown, the embodiment of the present invention provides a hydraulic nut which is satisfied with providing pre-tightening for the main bolt of the reactor pressure vessel and realizing the connection and sealing between the top cover of the reactor pressure vessel and the cylinder body. The hydraulic nut has a hydraulic nut series cylinder structure, so The hydraulic nut series cylinder structure includes 1. Spherical washer; 2. Primary oil cylinder; 3. Primary and secondary piston; 4. Secondary oil cylinder; .Stretching nut; 9. Hexagon socket head screw; 10. Compression block; 11. Compression ring one; 12. Compression ring two; 13. Oil block; 14. Hexagon socket plug; 15. Cone Threaded short tube; 16....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com