A method for on-line detection of the molecular ratio of alumina high-pressure dissolution pulp

A high-pressure dissolution, alumina technology, used in alumina/aluminum hydroxide, measuring devices, analytical materials, etc., can solve problems such as unstable pressure, inability to use normally, and generation of air bubbles, and achieve the effect of reducing system fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

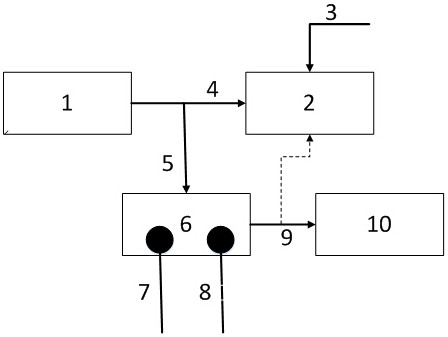

[0015] Such as figure 1 A method for on-line detection of the molecular ratio of alumina high-pressure stripping pulp is shown. The high-pressure stripping flash end tank 1 discharges the slurry for split flow, and 2-20% of the stripping slurry 5 enters the normal pressure flash tank 6 for thorough extraction. Flash to normal pressure; use the conductivity meter 8 to detect the conductivity of the stripping slurry after flashing to normal pressure online, use the thermocouple 7 to detect the temperature of the stripping slurry online, and combine chemical analysis to obtain the dissolution molecular ratio and conductivity and temperature The soft-sensing model of the relationship realizes the online detection of the molecular ratio of the high-pressure dissolution slurry.

[0016] The high-pressure dissolution temperature is 200~300°C.

[0017] The final tank pressure of high-pressure stripping and flash evaporation is 0.05~0.25MPa.

[0018] The exhausted steam 9 that splits...

Embodiment 2

[0022] Such as figure 1 A method for on-line detection of the molecular ratio of alumina high-pressure stripping pulp is shown. The high-pressure stripping flash end tank 1 discharges the slurry for split flow, and 2-20% of the stripping slurry 5 enters the normal pressure flash tank 6 for thorough extraction. Flash to normal pressure; use the conductivity meter 8 to detect the conductivity of the stripping slurry after flashing to normal pressure online, use the thermocouple 7 to detect the temperature of the stripping slurry online, and combine chemical analysis to obtain the dissolution molecular ratio and conductivity and temperature The soft-sensing model of the relationship realizes the online detection of the molecular ratio of the high-pressure dissolution slurry.

[0023] The high pressure dissolution temperature is 200~300℃.

[0024] The final pressure of the high-pressure stripping flash tank is 0.05~0.25MPa.

[0025] The exhausted steam 9 split and flashed is sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com