A Method for Measuring the Daily Fluid Production of Pumping Wells Based on Electrical Parameters

A technology of pumping wells and measurement methods, which is applied to the measurement of pumping wells in oil fields and the field of oil production in oil fields, to achieve the effects of less test parameters, improved accuracy, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

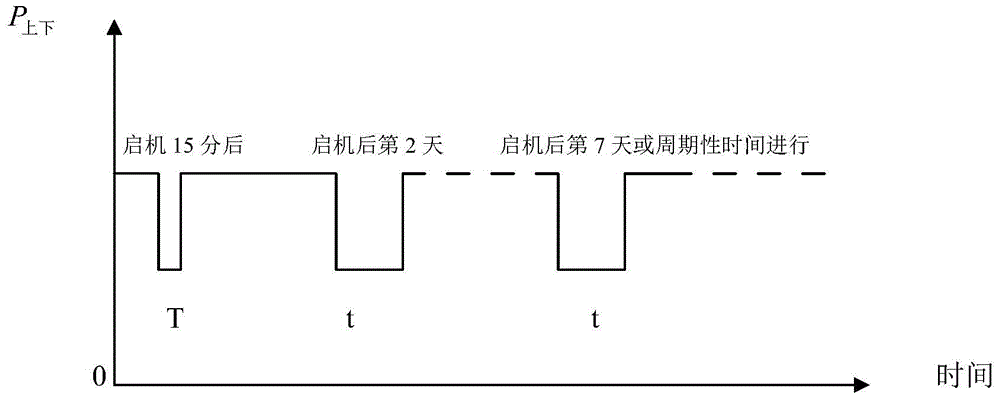

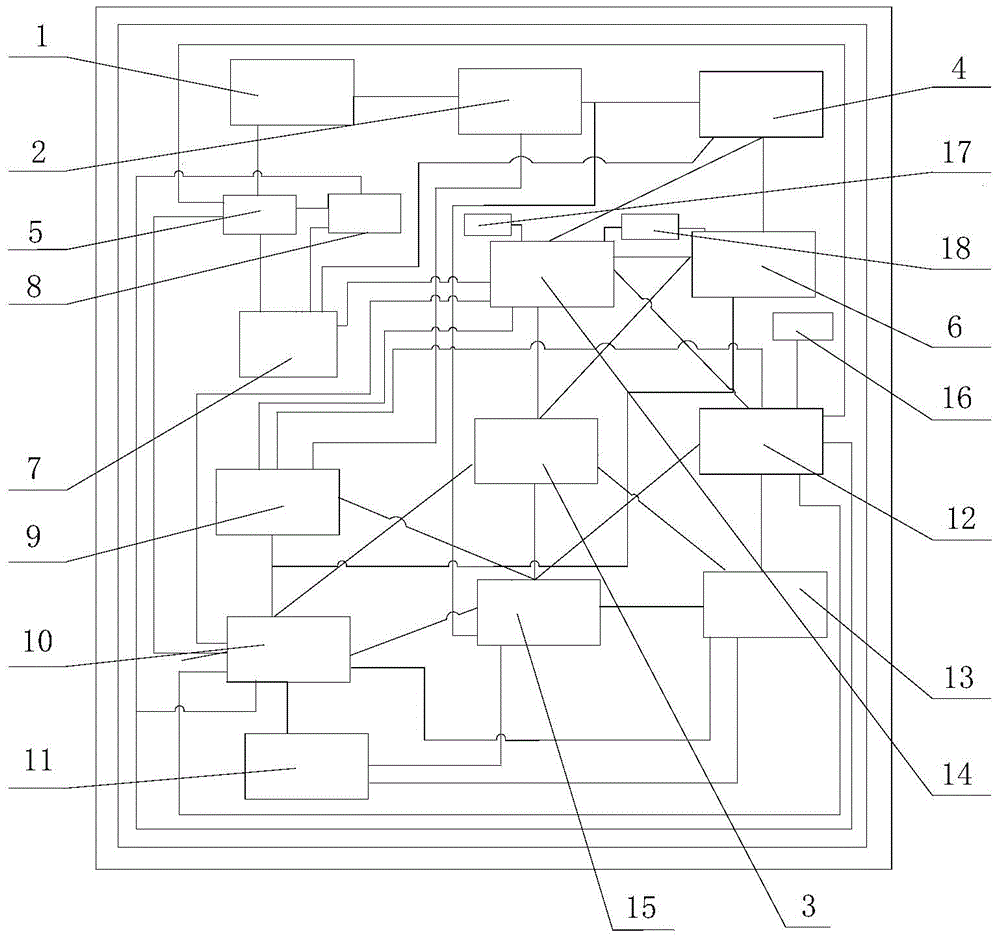

[0041] Specific embodiments 1. This embodiment is described as a method for measuring the daily fluid production of pumping wells based on electrical parameters, and the measurement method is:

[0042] During the normal working process of the pumping unit, the electrical parameters of the pumping well unit are collected in real time, and then the net torque of the corresponding pumping unit is calculated according to the electrical parameters, and at the same time, the crank of the pumping unit is determined to run to the top dead point of the corresponding pumping unit time and the time of bottom dead center;

[0043] After the pumping well has been working continuously for two days, the daily fluid production of a single well is measured by periodic parameter adjustment operation. The period is 2 to 30 days. The number of strokes N is converted to N after parameter adjustment 2 , and lasts for a running time t, N 2 ≠N, t is a time parameter greater than 8 minutes and less ...

specific Embodiment approach 2

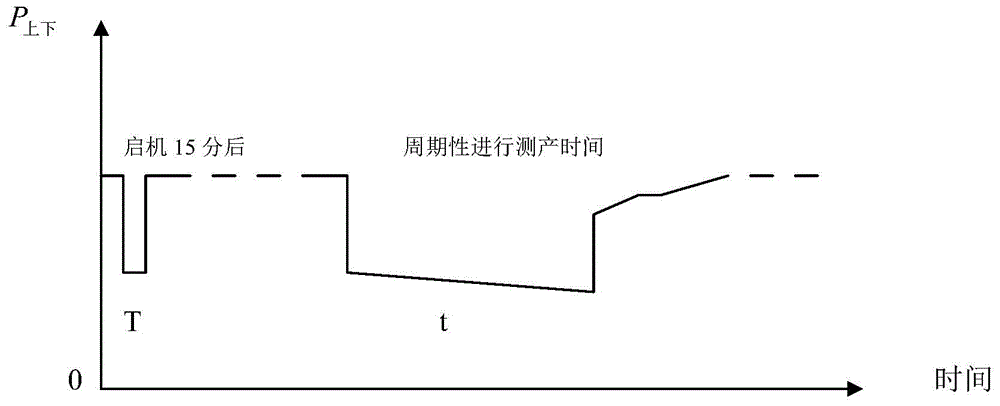

[0058] Specific embodiment 2. This embodiment is a further limitation of the method for measuring the daily fluid production of pumping wells based on electrical parameters described in specific embodiment 1. In this embodiment, the dynamic fluid surface coefficient correction process is also included. Specifically for:

[0059] Superimpose the net torque data of multiple consecutive up and down strokes within the first 1-2 minutes after parameter adjustment to obtain the superimposed torque P of up and down strokes 6上下 ;

[0060] According to the P obtained above 5上下 and P 6上下 Get coefficient K 1 ,

[0061] When N 2 When 1 =P 5上下 -NP 6上下 / N 2 ;

[0062] When N 2 When >N, K 1 =P 6上下 -N 2 P 5上下 / N;

[0063] Superimpose the net torque data of multiple consecutive up and down strokes within the last minute after parameter adjustment to obtain the superimposed torque P of up and down strokes 7上下 ;

[0064] According to the P obtained above 7上下 and P 8上下 Get coef...

specific Embodiment approach 3

[0069] Specific Embodiment 3. This embodiment is a further limitation of the method for measuring the daily fluid production of pumping wells based on electrical parameters described in Embodiment 1. In this embodiment, the stroke times N after the parameter adjustment 2 Greater than or equal to 0, and less than or equal to 1.5N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com