Electrostatic adsorption welding spot ultrasonic automatic detection device and method

An automatic detection device, electrostatic adsorption technology, which is applied in the analysis of solids, motor vehicles, transportation and packaging using sonic/ultrasonic/infrasonic waves, which can solve the problems of slow moving speed, relatively high surface roughness requirements for adsorption, and loud motion noise. , to achieve the effect of easy control, traceable query, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

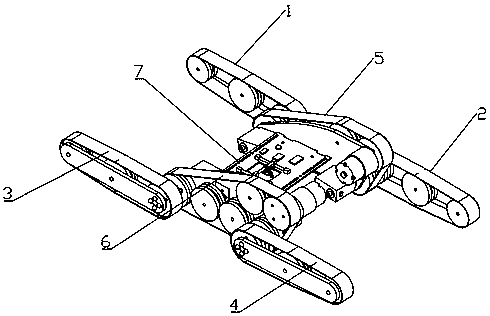

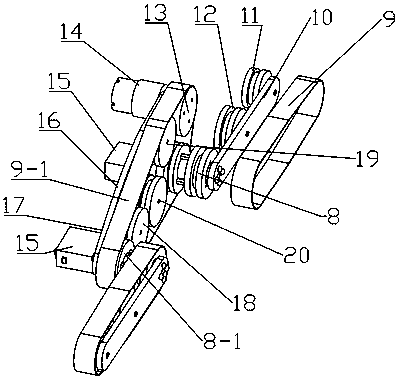

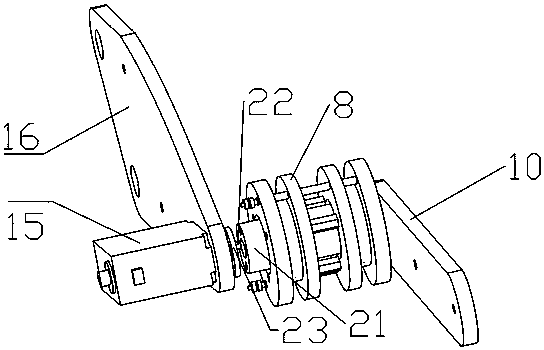

[0033] see Figure 1 to Figure 12 As shown, the electrostatic adsorption type solder joint ultrasonic automatic detection device of the present invention includes a wall climbing unit and a scanning unit, and the scanning unit is fixed on the wall climbing unit; the wall climbing unit is composed of an auxiliary arm A1, an auxiliary arm B2 , auxiliary arm C3, auxiliary arm D4, active arm A5, active arm B6 and workbench 7, auxiliary arms A~D are respectively composed of track A9, guide wheel 11, support wheel 12 and tension plate 10, active arm A, B is composed of drive wheel 13, deceleration motor 14, steering gear 15, side plate 16, crawler belt B9-1, brush slip ring 17, support wheels B~D18, 19, 20; auxiliary arm D4 and active arm B6 pass through the auxiliary arm The active wheel A8 is connected, the auxiliary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com