Power module aging device

An aging device and power module technology, applied in the direction of power supply testing, etc., can solve the problems of low power consumption, low cost, large area of the aging room, and the aging room is too cumbersome, etc. space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

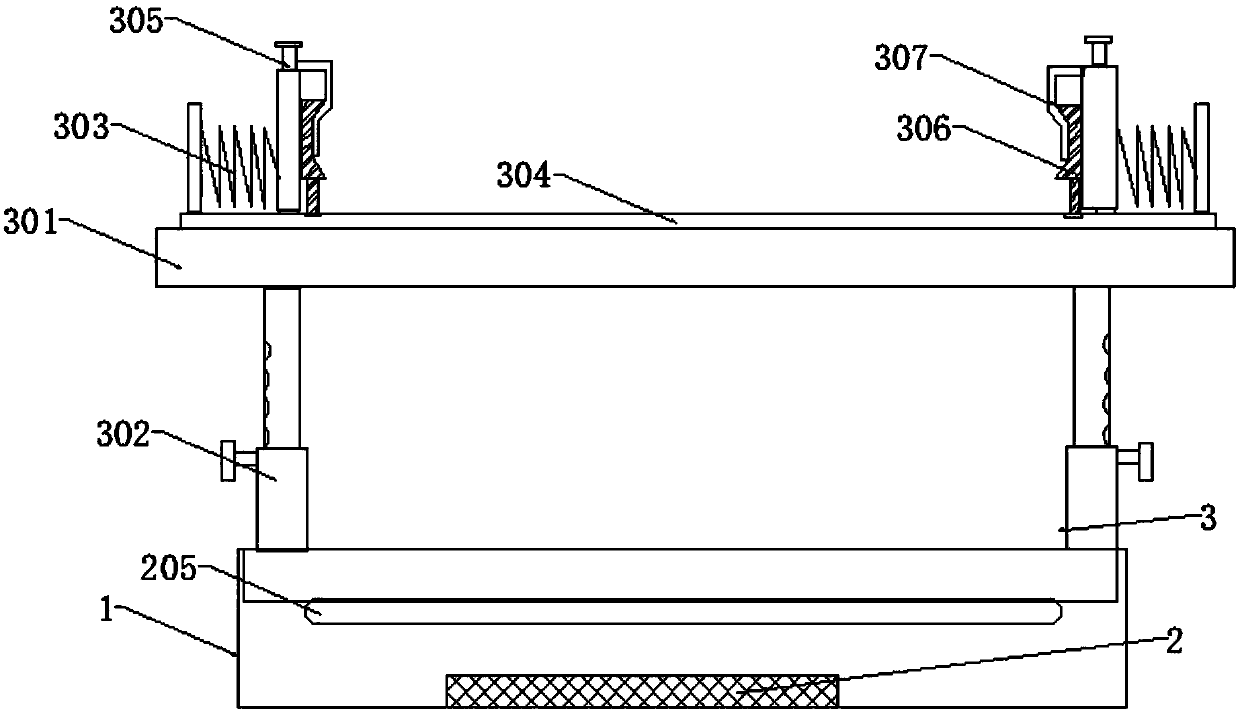

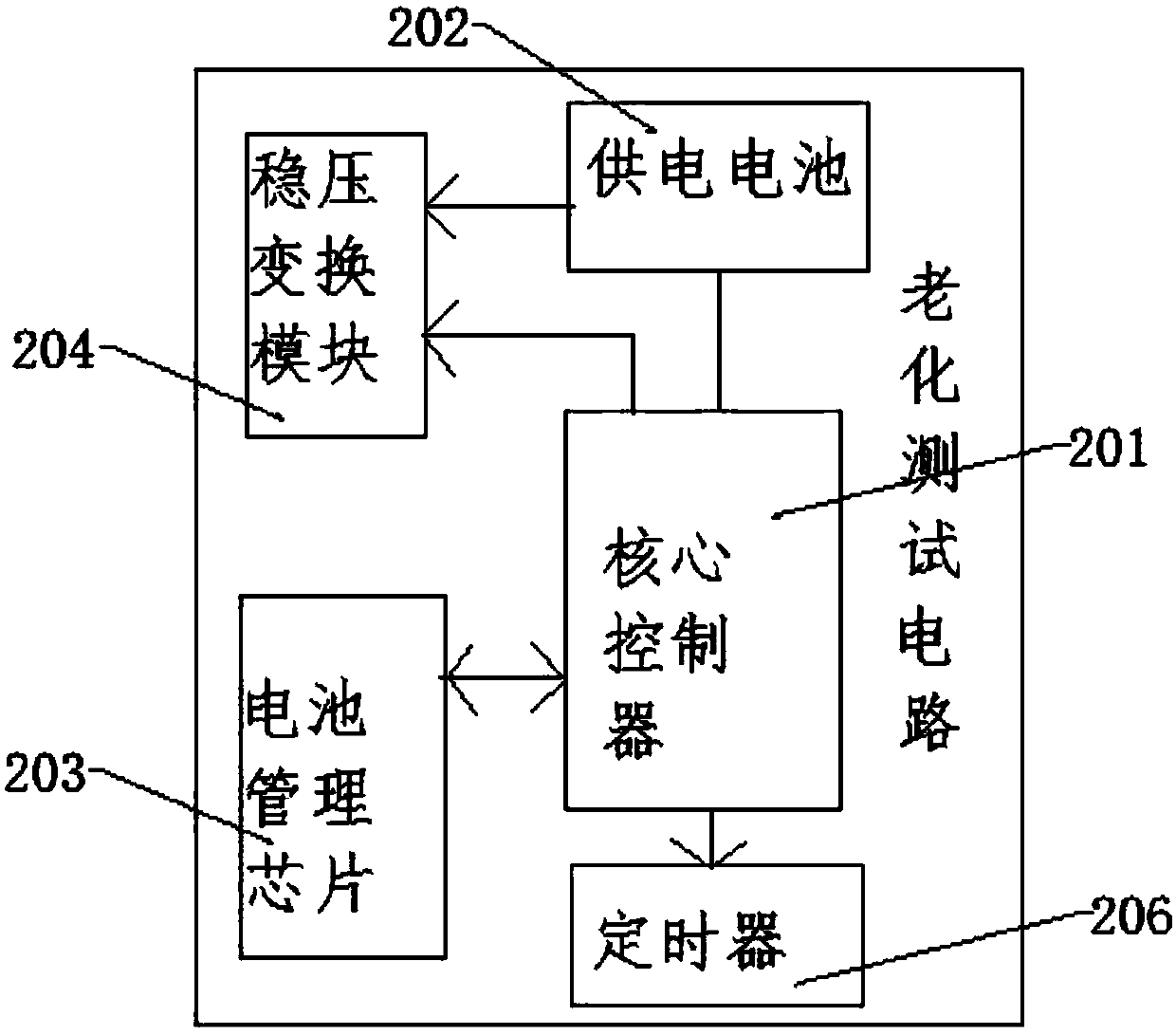

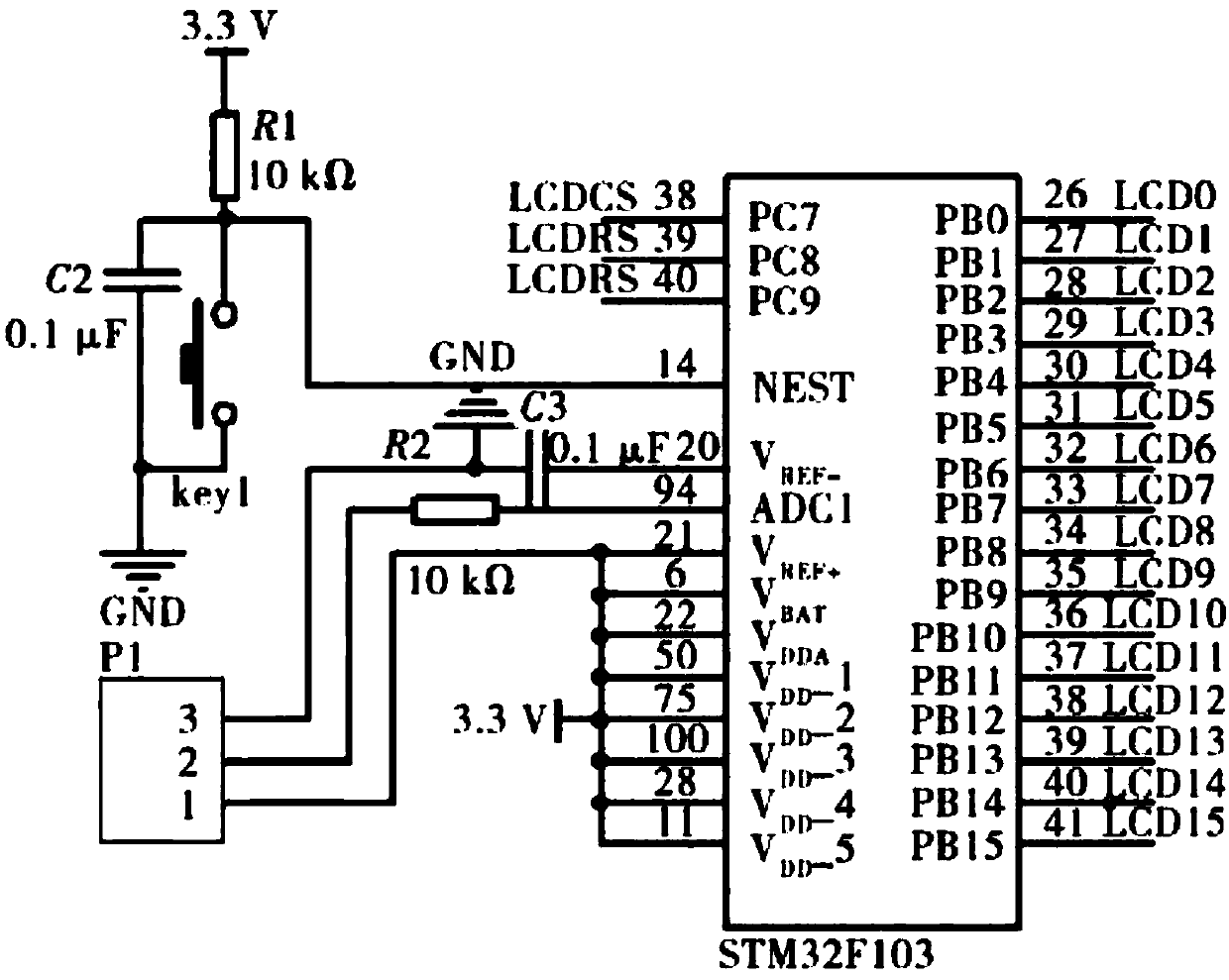

[0027] Such as figure 1 As shown, the present invention provides an aging device for power modules, including an aging box 1, the aging box 1 is made of polytetrafluoroethylene into a rectangular box, which has good insulation protection performance and is easy to move and carry; the inside of the box It is divided into two layers by insulating partitions. The aging test circuit 2 is installed at the bottom of the box, and the power supply fixing mechanism 3 is installed above the partition. The power supply fixing mechanism 3 is used to fix the power supply to be aged. Aging test and corresponding analysis and processing;

[0028] The power supply fixing mechanism 3 includes a fixed base plate 301, the fixed base plate 301 is made of an insulating plastic plate, mounting holes are drilled at the four corners of the fixed base plate 301, and a telescopic support frame 302 is inserted into the mounting hole, and the telescopic support frame The other end of 302 is fixedly embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com