Intelligent temperature-controlled storage battery formation tank

An intelligent temperature control and battery technology, applied in lead-acid battery, lead-acid battery construction, temperature control, etc., can solve the problem of inability to improve the formation effect, and achieve the effect of optimizing the formation effect, stabilizing the ambient temperature, and improving the formation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

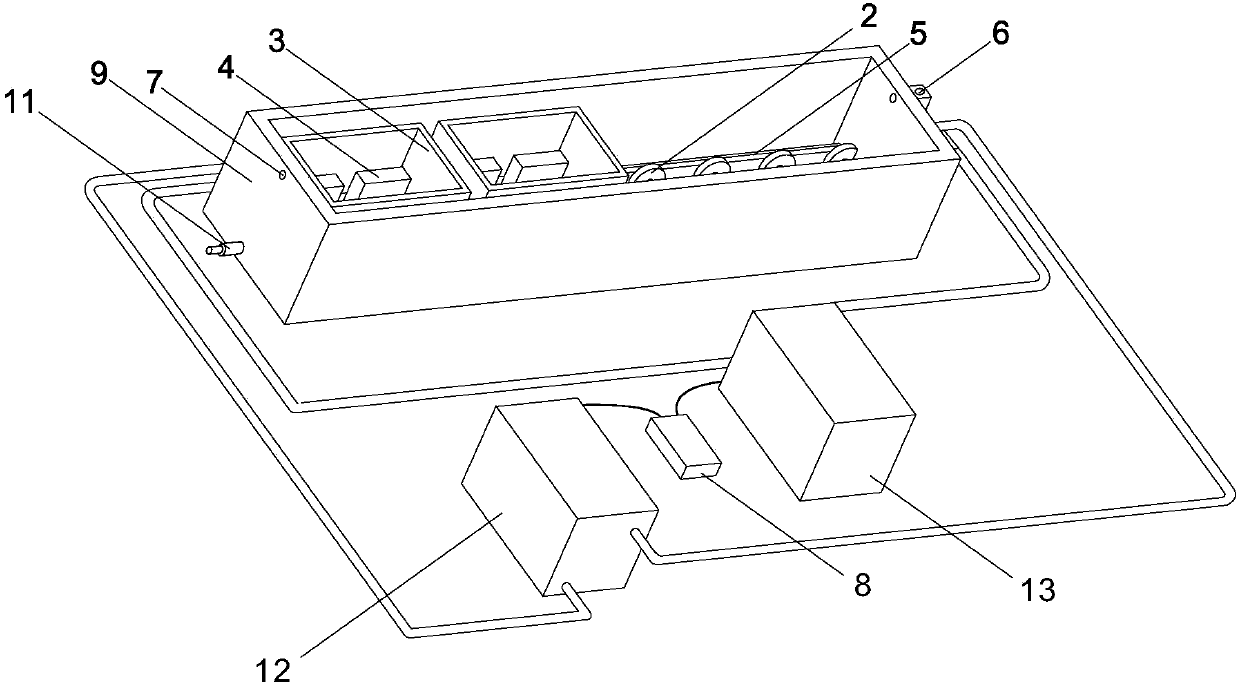

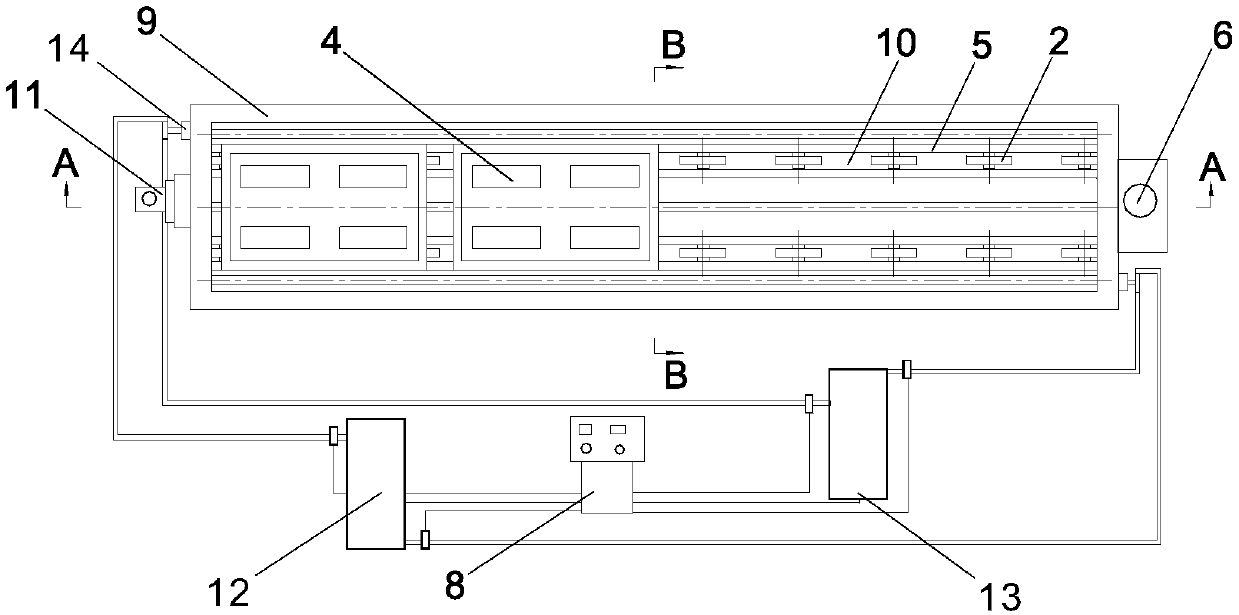

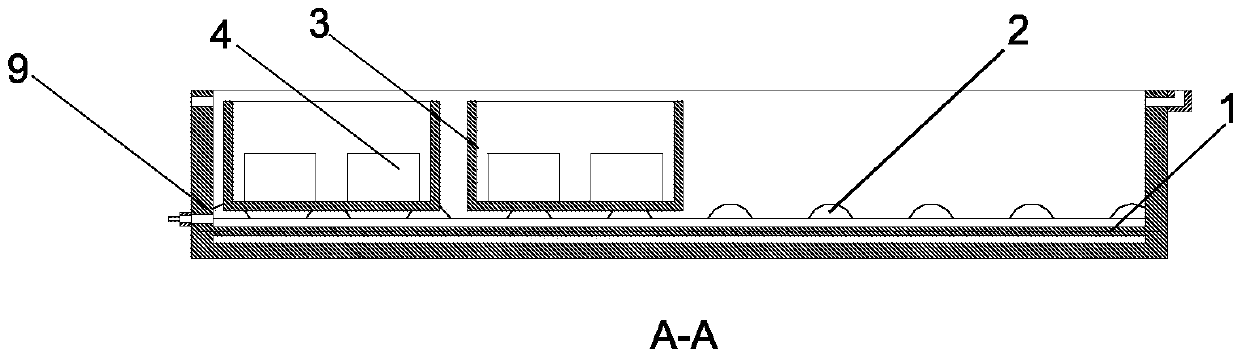

[0021] like figure 1 , figure 2 , image 3 , Figure 4 As shown in the figure, an intelligent temperature control battery is formed into a tank, which includes a cuboid tank body 9, a battery transfer track is arranged in the tank body 9, and a temperature control module 1 is also arranged in the tank body 9, and the temperature control module 1 is fixed in the tank. The bottom of the body 9 is lower than the battery transfer track. The tank body 9 is provided with a chiller 12 and a hot water machine 13. The chiller 12 is provided with a refrigeration compressor, and the hot water machine 13 is provided with a heater. On the temperature module 1 , water pumps are provided in the chiller 12 and the hot water machine 13 , and each water pump is electrically connected to a controller 8 . The chiller 12 and the hot water machine 13 are both provided with temperature setting panels, the tank body 9 is provided with a temperature sensor, and the temperature setting panel and t...

Embodiment 2

[0024] The battery transfer track includes three roller brackets 5 and three rows of rollers 2 . The rest are the same as in Example 1.

[0025] When the battery 4 does not enter the tank body 9, it is necessary to cool the water to 7°C and keep it for 0.5 hours. When the battery finished standing, the water temperature was adjusted to 18°C for 2 hours. As the battery 4 was charged and discharged, the water temperature was adjusted to 22° C. until the formation was completed.

Embodiment 3

[0027]The battery transfer track includes four roller brackets 5 and four rows of rollers 2 . The rest are the same as in Example 1.

[0028] When the battery 4 does not enter the tank body 9, it is necessary to cool the water to 8°C and keep it for 0.5 hours. When the battery 4 finished standing, the water temperature was adjusted to 20° C. for 1 hour. As the battery 4 was charged and discharged, the water temperature was adjusted to 25° C. until the formation was completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com