Aircraft panel vacuum chuck type flexible assembly fixture system

A technology of flexible assembly and aircraft siding, applied in the field of machinery, can solve problems such as the small number of flexible tooling, the lack of popularization of aviation companies, and the lack of specifications and guidance for flexible tooling, so as to improve assembly quality, save production time and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

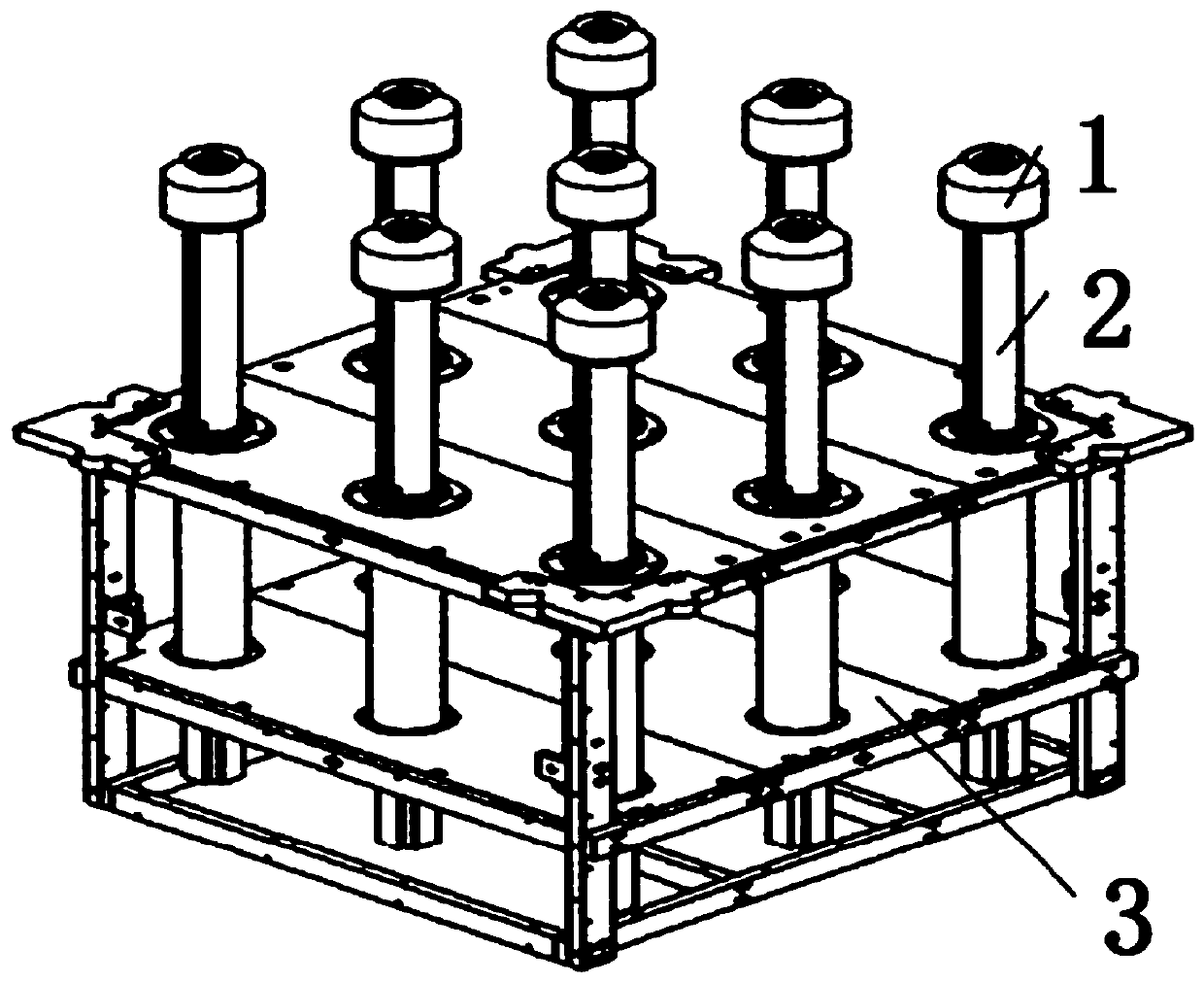

[0019] Such as figure 1 , The mechanical structure of the flexible tooling platform is mainly composed of three parts: positioning and clamping system, transmission system, and support system. The main function of the positioning and clamping system is to fix the position of the aircraft panel in space for subsequent processing or assembly; the main function of the transmission system is to enable the pillar to move up and down and send the suction cup to the proper height; the supporting system mainly The function is to support and fix the transmission system, so that each transmission system has its own fixed position, making the structure stable and reliable.

[0020] The positioning and clamping system is composed of a hollow support body with a spherical groove on the top, a suction cup, a positioning piece, an incomplete sphere, etc. The incomplete sphere and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com