Circulation system with two tracks of internal track and external track

A circulation system and dual-track technology, applied in the field of internal and external double-track circulation systems, can solve problems such as scalding of film clamps and affecting product quality, and achieve the effects of reducing friction coefficient, smooth transition, and preventing transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

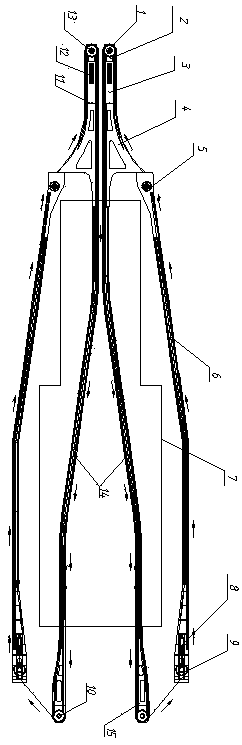

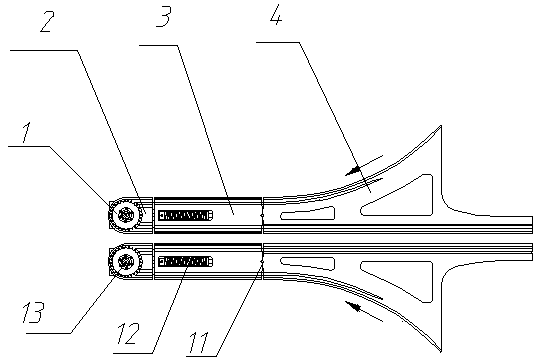

[0022] like figure 1 and figure 2 An internal and external dual-track circulation system is shown, including a film inlet track, a film closing track 15, an inner track 14 of the drying room and an outer track 6 of the drying room.

[0023] The film feeding track is arranged at the leftmost end outside the drying room 7, and the film feeding track includes two symmetrical film feeding guide plates, the inner side of the film feeding guide plate is provided with an inner chain guide groove, and the outer side is provided with an outer The chain guide groove is provided with a sprocket 1 at the leftmost end of the film feed guide plate; the film feed guide plate includes two semicircular guide plates 2, two straight guide plates 3 and two symmetrical arc guide plates 4; The curved guide plate 4 is fixed on the frame, and the inner side of the curved guide plate 4 is provided with a straight guide groove, and the outside is provided with an arc-shaped guide groove; One side gr...

Embodiment 2

[0032] The rest are the same as in Example 1, the difference is that the outer track 6 of the drying room is arranged in an outer casing, and cold air is also passed through the outer casing, so that the cooling effect of such an arrangement is better, and for some drying rooms For equipment with a relatively short outer track, the distance from the film holder to the film inlet track is short, the cooling time is not long enough, and the cooling effect is not enough. The outer shell can be set in this way to speed up the cooling.

Embodiment 3

[0034] The rest are all the same as in Embodiment 1, except that one end of the straight guide plate 3 is connected with the arc guide plate 4 through a rotating shaft 11, and the straight guide plate 3 can swing on the arc guide plate 4 through the rotating shaft 11. After the film is unwound, it is inevitable that there will be partial position deviation. If the film feeding track is fixed and cannot be adjusted, it will cause asymmetry between the left and right sides when the film clamp is clamped, which will affect the quality of the film output, or if the deviation is large If it is too large, one side of the film will not be able to be clamped, which will affect the production.

[0035]Further, a swing drive mechanism that drives the two straight guide plates 3 to swing can be set on the film-feeding track, and a position sensor is also set on it to automatically adjust the position of the film-feeding track according to the position of the film, thereby Make sure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com