Velvet touch health fabric with pits on polyurethane layer

A polyurethane layer and pit technology, applied in the field of fabrics and textile fabrics, can solve the problems of monotonous appearance, waste, uncomfortable touch, etc., and achieve the effect of enhancing the three-dimensional effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

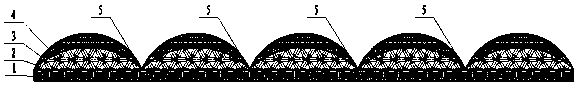

[0016] see figure 1 A polyurethane layer is provided with dimpled velvet tactile sanitary fabrics, including a base cloth layer, and an absorption layer, a flow diversion layer and a flocking layer are sequentially arranged outside the base cloth layer; water-based polyurethane adhesives are passed between the layers Composite together, and use cotton yarns to sew and compress at intervals; the base fabric layer is woven with spandex fibers; the absorption layer is filled with SEE ecological cotton; the diversion layer is made of blended cotton fibers and hemp fibers; The flocking layer is a long-pile spraying layer.

[0017] Preferably, the distance between the cotton yarns is 5-10mm.

[0018] The back side of the base cloth layer is provided with a lining fabric layer, and the lining fabric layer includes a cloth bottom layer, a breathable layer and a polyurethane layer from bottom to top, the breathable layer is provided with air holes, and the polyurethane layer is provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com