Automatic pushing-pulling device of overhead manned cable car

An overhead passenger and cable car technology, used in motor vehicles, funicular railways, railway vehicles, etc., can solve problems such as unsuccessful application cases, and achieve the effect of eliminating chain drop phenomenon, eliminating operating noise, and improving turnover efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

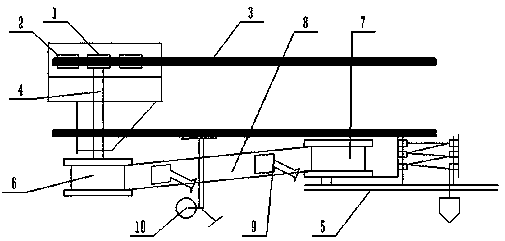

[0018] The present invention is installed in the second corner of cable car, comprises guiding part and at least one driving part, and described driving part comprises driving wheel 1 and is arranged on the anti-tension wheel 2 of driving wheel both sides, and described driving wheel is arranged on On one side of the upper layer steel wire rope 3 of the cable car, two anti-tension wheels 2 are arranged on the other side of the upper layer steel wire rope 3, and the driving wheel is connected to the guide part through the transmission shaft 4, and the guide part includes an arc-shaped coating suitable for the arc of the corner. Rail 5, the two ends of described rail 5 are respectively provided with nose guide wheel 6 and machine tail guide tail wheel 7, and described drive wheel 1 is connected machine head guide wheel 6 or machine tail guide tail wheel 7, and described machine Drive belt 8 between head guide wheel 6 and machine tail guide tail wheel 7, the outside of described d...

Embodiment 2

[0023] There are two driving parts, and the driving wheels 1 are respectively connected to the nose guide wheel 6 and the tail guide wheel 7 .

[0024] Further, the tail guide tail wheel is connected with the weight type tail wheel automatic tensioning device.

[0025] The advantage is that, due to the addition of the tail drive, the transmission force of the pushing device is doubled, and the passenger lift can also be pushed normally at this place. At the same time, the use of the tail tension wheel can adjust the tension of the main transmission chain in real time. The tightening force basically eliminates the phenomenon of chain dropping.

Embodiment 3

[0027] Both the anti-tensioning wheel 2 and the driving wheel 1 are provided with an automatic push clutch mechanism, and the automatic push clutch mechanism is connected to an inductor arranged above the running direction of the cable car.

[0028] The nose guide wheel 6 and the tail guide tail wheel 7 are cylinders with round edges, a plurality of rollers are arranged between the nose guide wheel 6 and the tail guide tail wheel 7, and the transmission belt 8 is a 100mm wide ring belt. It is a tensionable guide roller. The driving part is a double drive wheel. When installing, the two drive wheels are close to the upper wire rope of the cable car, but do not touch the wire rope. The inner side of the wire rope is a pneumatic tensioner.

[0029] Working principle: When the cable car chair moves to the area of the push-pull device, it will trigger the induction device at the entrance of the push-pull device, and the device will send a signal to the solenoid valve of the pneum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com