Production system capable of improving purity of iso-octyl palmitate

A technology for isooctyl palmitate and a production system, which is applied in the field of production systems for improving the purity of isooctyl palmitate, can solve problems such as the impact on the final product quality and the quality of finished products, and achieves improved purity, safe drying process, and saving of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

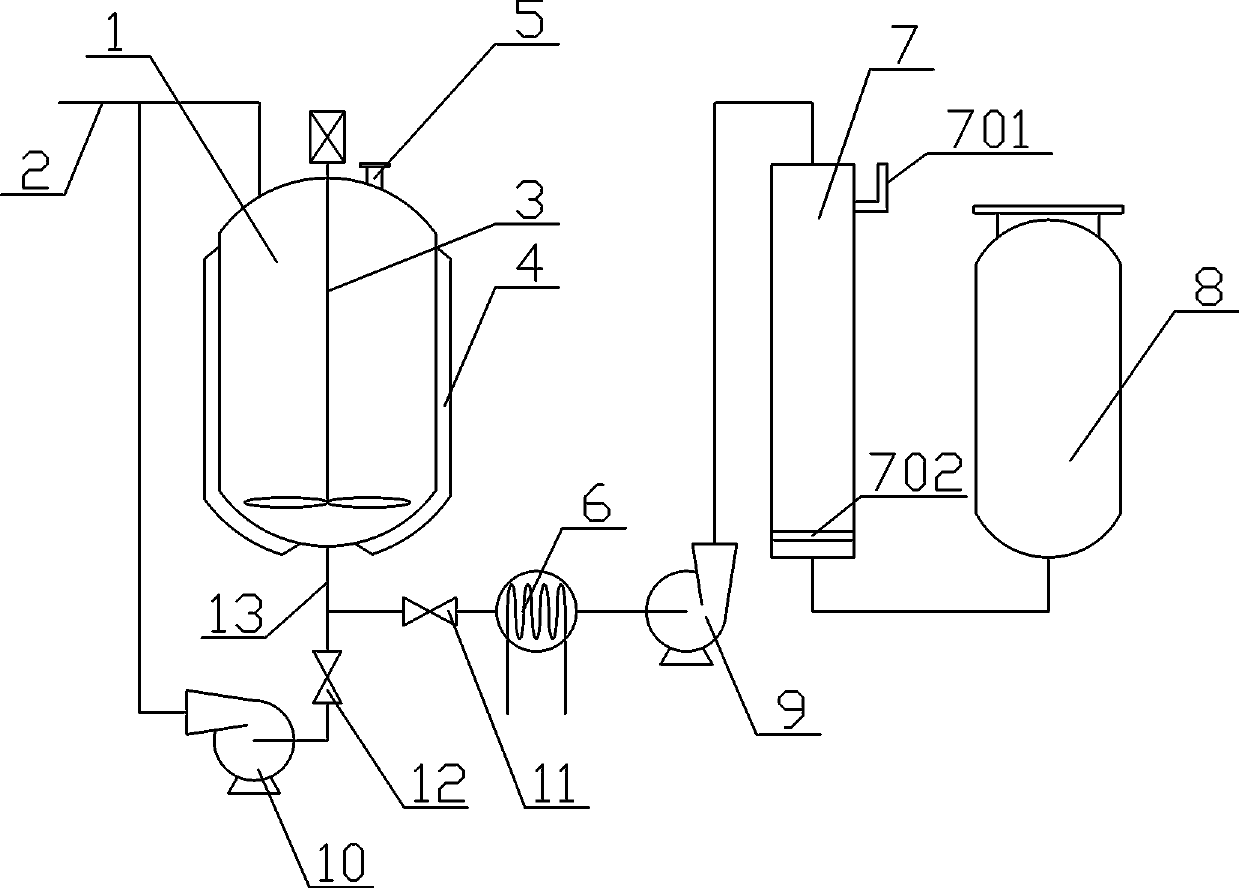

[0018] As shown in the figure, a production system capable of improving the purity of isooctyl palmitate includes a reaction tank 1, a drying tower 7 and a finished product collection tank 8, and the top of the reaction tank 1 is provided with a feed pipe 2 and a first exhaust port 5, The reaction tank 1 is provided with a stirring device 3, the side wall of the reaction tank 1 is provided with a heating jacket 4, the bottom of the reaction tank 1 is provided with a discharge pipe 13, and the discharge pipe 13 is divided into two branch pipes, one of which is connected to the feed pipe. 2 are connected, and the other is connected with the feed port at the top of the drying tower 7, and the discharge port at the bottom of the drying tower 7 is connected with the finished product collection tank 8.

[0019] In a preferred solution, a branch pipe connecting the discharge pipe 13 with the feed pipe 2 is provided with a second delivery pump 10 and a second valve 12 .

[0020] In a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com