Composite false-twisting satin fabric and production process thereof

A production process and fabric technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve problems such as inability to produce, mutual interference, and easy to break wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

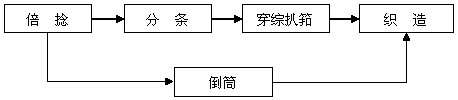

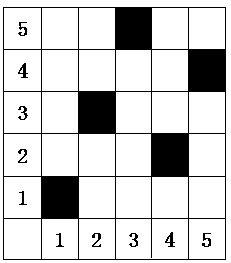

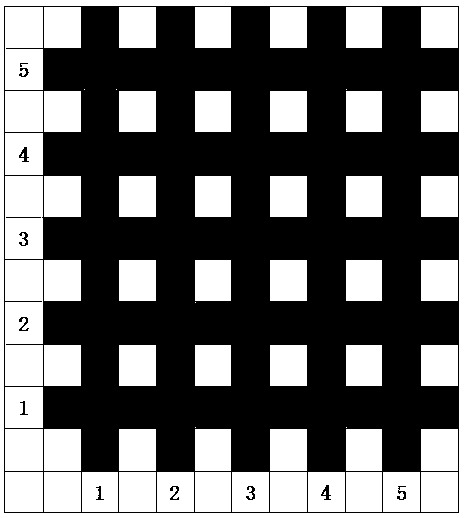

Method used

Image

Examples

Embodiment 1

[0034] 1. Silk treatment

[0035] a. Winding: Use a winding machine, set the winding weight to 0.56kg, the winding time to 259 minutes, and the curling force to 12g to wind;

[0036] b. Two-for-one twisting: use a two-for-one twisting machine, set the spindle speed to 11000r / min, increase the expansion force beads to 0.9*1 grain, and perform two-for-one twisting with a wrap angle of 360°;

[0037] c. Segment warping: set the speed of the large drum at 280m / min, the inverted axis at 50m / min, and equip with the No. 3 tension cap. The warping tension is controlled at 6-7g, and the inverted axis tension is controlled at 1.7-1.8kg. Carry out warping according to 604 grains*31 strips;

[0038] d. Heald threading: 10 pieces of healds are used, and the healds are threaded in a straight-through method;

[0039] 2. Weft processing

[0040] a. Winding: Use a winding machine for winding, set the winding weight to 0.69kg, the winding time to 242 minutes, and the curling force to wind at...

Embodiment 2

[0047] 1. Silk treatment

[0048] a. Winding: Use a winding machine, set the winding weight to 0.57kg, the winding time to 260 minutes, and the curling tension to 12.5g for winding;

[0049] b. Two-for-one twisting: use a two-for-one twisting machine, set the spindle speed to 11000r / min, increase the expansion force beads to 0.9*1 grain, and perform two-for-one twisting with a wrap angle of 360°;

[0050] c. Segment warping: set the speed of the large drum at 280m / min, the inverted shaft at 50m / min, and equip with No. 3 tension cap, control the warping tension at 6-7g, and control the tension at the inverted shaft at 1.8kg, according to 604 grain * 31 for warping;

[0051] d. Heald threading: 10 pieces of healds are used, and the healds are threaded in a straight-through method;

[0052] 2. Weft processing

[0053] a. Winding: Use a winding machine for winding, set the winding weight to 0.70kg, the winding time to 240 minutes, and the curling force to wind at 12g;

[0054]...

Embodiment 3

[0060] 1. Silk treatment

[0061] a. Winding: Use a winding machine, set the winding weight to 0.57kg, the winding time to 260 minutes, and the curling tension to be 13g for winding;

[0062] b. Two-for-one twisting: use a two-for-one twisting machine, set the spindle speed to 11000r / min, increase the expansion force beads to 0.9*1 grain, and perform two-for-one twisting with a wrap angle of 360°;

[0063] c. Segment warping: set the speed of the large drum at 280m / min, the inverted shaft at 50m / min, and equip with No. 3 tension cap, control the warping tension at 6-7g, and control the tension at the inverted shaft at 1.8kg, according to 604 grain * 31 for warping;

[0064] d. Heald threading: 10 pieces of healds are used, and the healds are threaded in a straight-through method;

[0065] 2. Weft processing

[0066] a. Winding: Use a winding machine for winding, set the winding weight to 0.70kg, the winding time to 240 minutes, and the curling force to wind at 13g;

[0067...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com