Flood drainage system of dry-type tailing reservoir

A tailings pond and dry-type technology, which is applied in the direction of waterway system, sewage discharge, drainage structures, etc., can solve the problems of loss of storage capacity, high construction cost of flood drainage shaft, and high construction difficulty, so as to increase storage capacity, shorten flood discharge time, The effect of increasing flood control storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

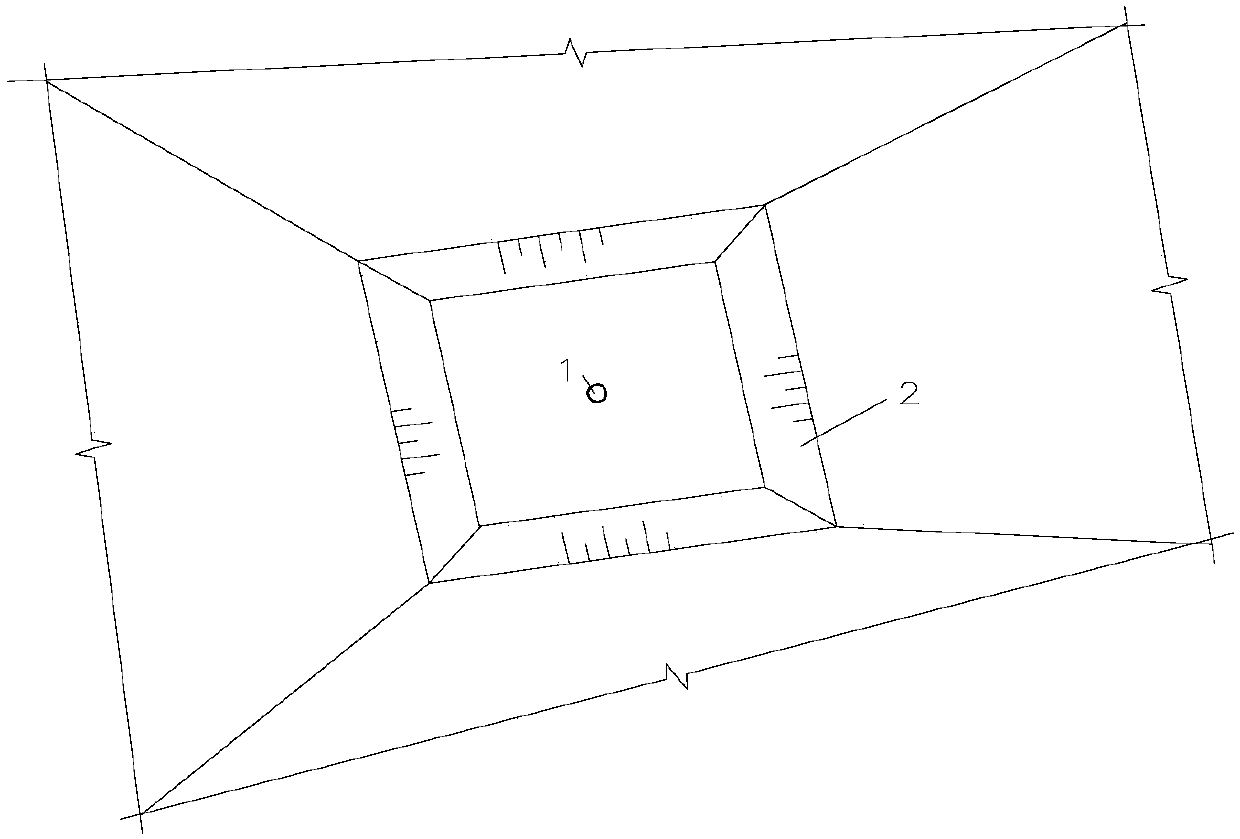

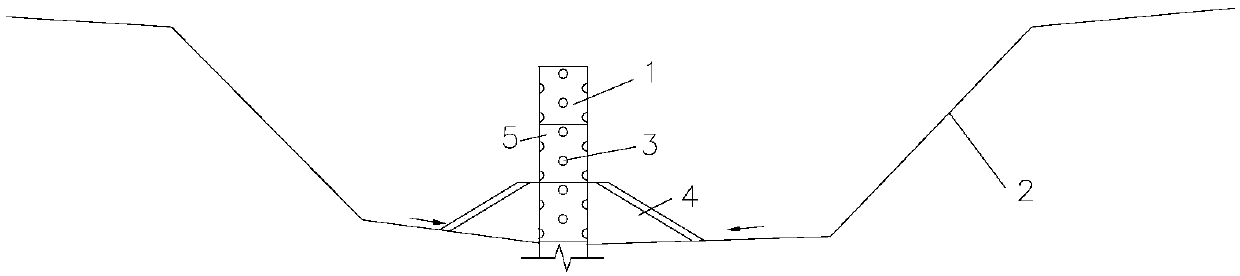

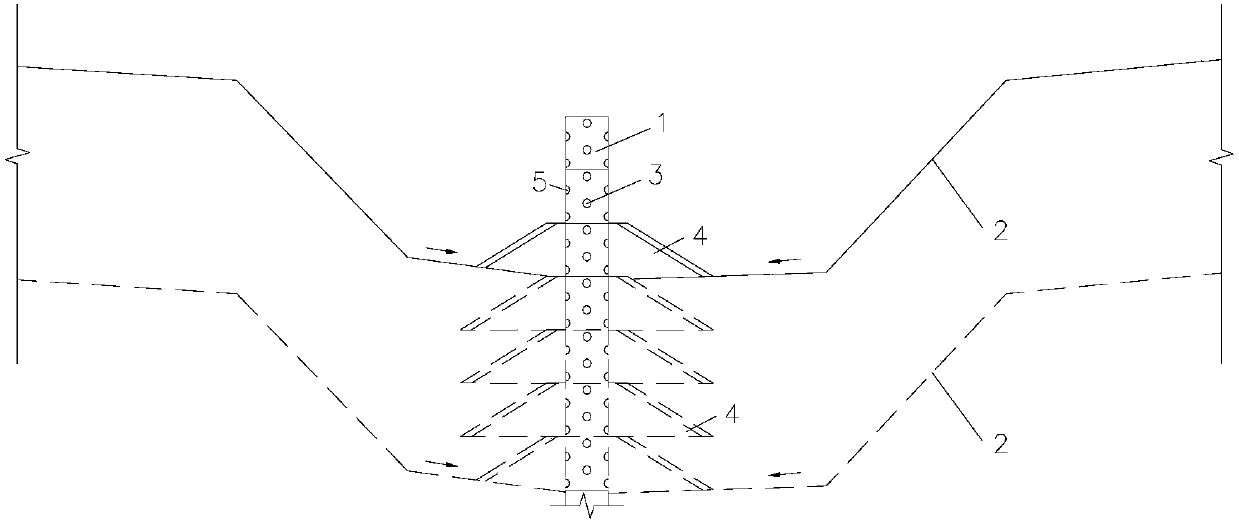

[0031] Such as Figure 1-Figure 5 Shown, the specific structure of the flood discharge system of the dry tailings pond of the present invention is as follows:

[0032] A flood control pool 2 is built around the flood discharge shaft 1. The flood discharge shaft 1 adopts a metal structure well body and a reinforced concrete well seat. The well body is opened with a backwater hole 3, which is arranged in a plum blossom shape. The outer side of the backwater hole 3 is connected with the flange plate 6 , and the outer side of the joint between the flange plate 6 and the backwater hole 3 is covered with a geotextile 7 . The flange plate 6 is an annular steel plate, the flange plate 6 and the return hole 3 are connected by bolts, and the outer layer of the flange plate 6 is welded with steel mesh 8 ( Figure 4 , Figure 5 ).

[0033] The height of the flood discharge shaft 1 exposed to the flood control pool 2 is 4 to 5 meters, and the bottom 2 to 3 meters of the exposed part is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plane area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com