Digital three-direction displacement measurement device and setting error controlling method thereof

A measuring device and three-way displacement technology, applied in the direction of measuring device, optical device, radio wave measuring system, etc., can solve the problems of zero-point drift, poor anti-interference ability, difficulty in precise positioning and calibration of inductive sensors, etc., and achieve zero-point drift. , The effect of strong anti-interference ability and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the application of the present invention will be described in detail below in conjunction with the accompanying drawings.

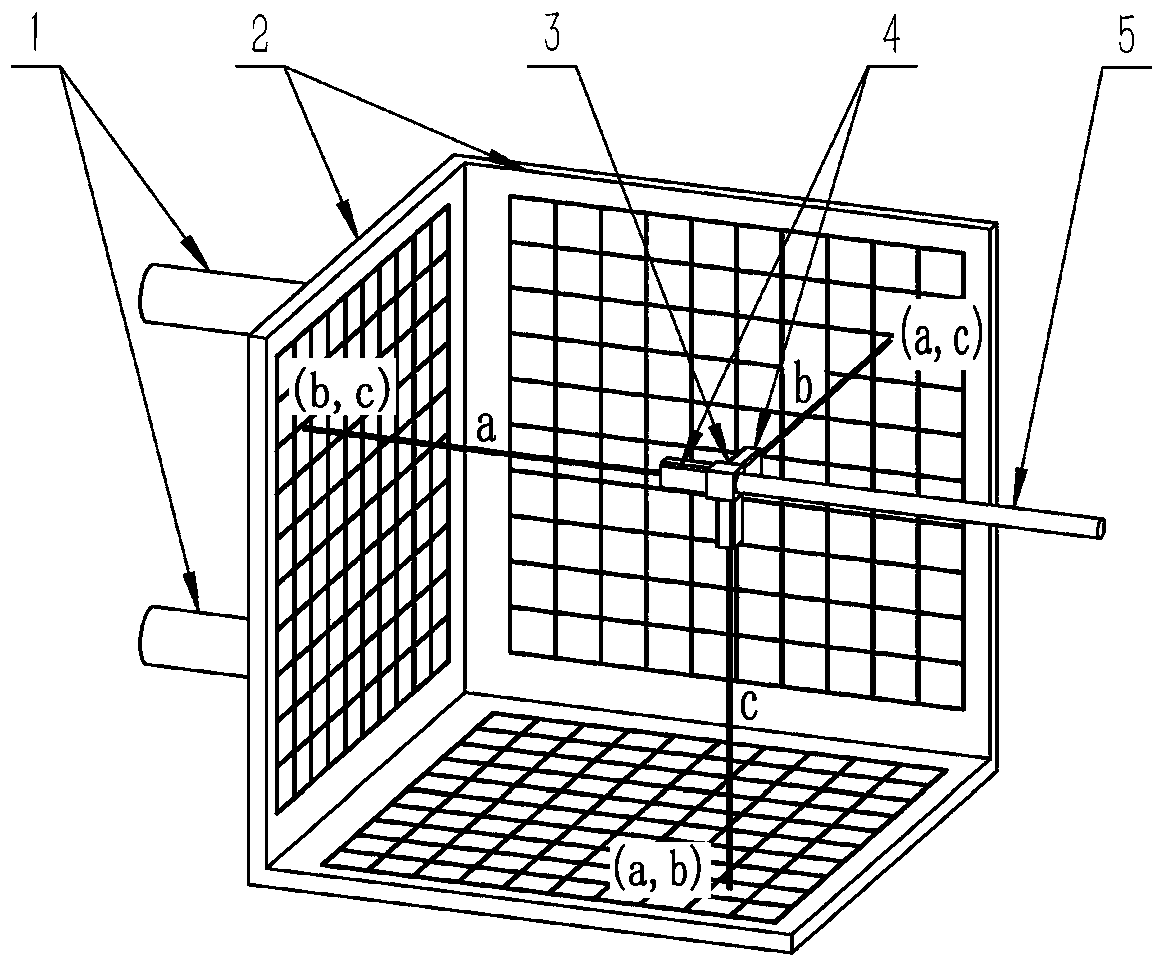

[0025] figure 1 It shows the main part of the digitized three-way displacement measuring device provided by the application of the present invention, and the dustproof soft cover is not shown in the figure.

[0026] Among them, the three-way reflector 2 is fixed together by three square reflective panels with grid scales, and the installation and fixing part 1 of the three-way reflector 2 is fixed on the measured object that needs to detect the expansion displacement. The plane of the reflector 2 is usually parallel to the front, back, left, and right directions of the factory building, and the other direction is the vertical direction. The measured objects that need to detect expansion displacement on thermal equipment usually include cold wall headers, downcomers, high temperature superheater inlet headers,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com