Cell and production method thereof

A battery and positive electrode technology, applied in the field of battery and its preparation, can solve the problems of difficult core winding, the total thickness of the core group, thick winding core, and complex design and manufacturing process of multi-pole tabs, etc., to achieve simple operation, easy realization of manufacturing process, The effect of excellent magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

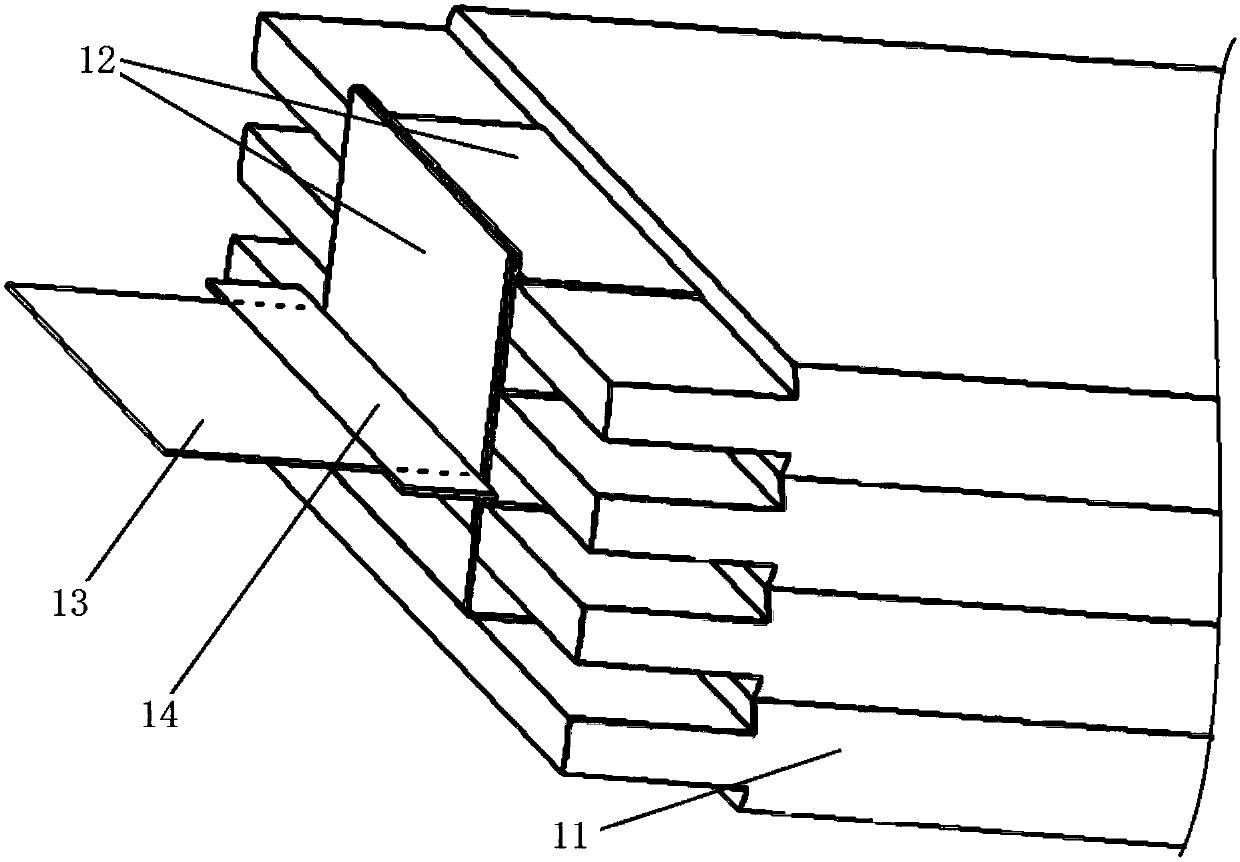

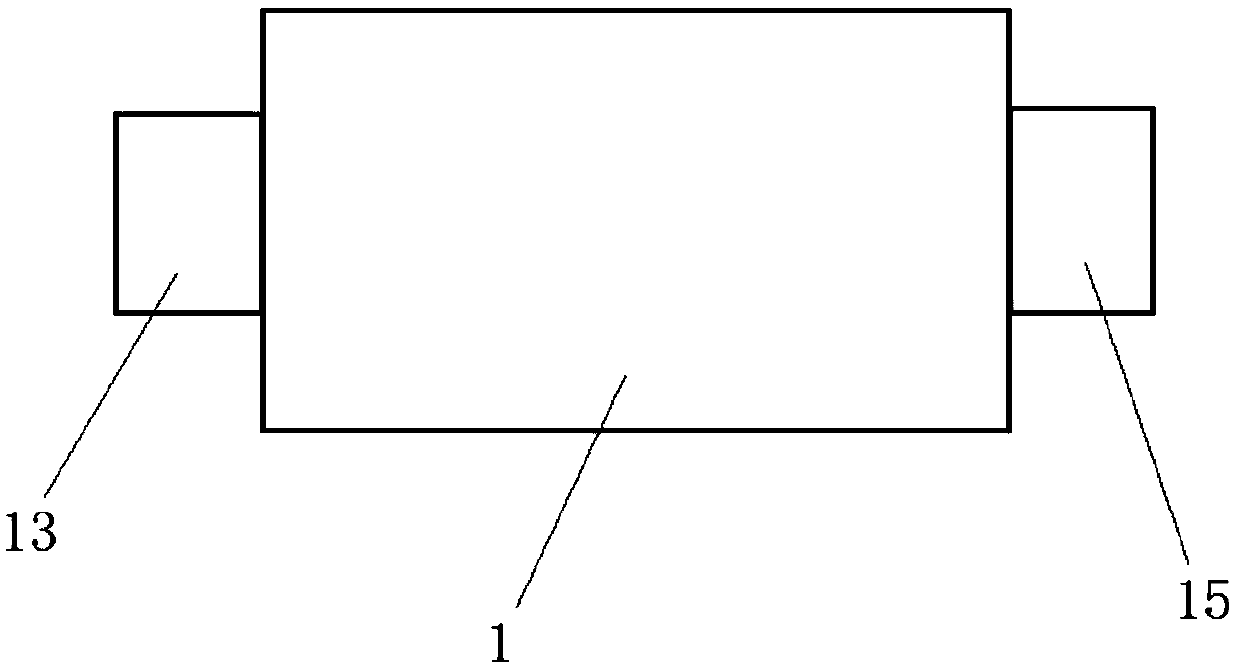

[0064] This embodiment provides a battery, such as figure 1 and figure 2 As shown, the battery 1 in this embodiment includes a winding core assembly, a connection structure, and tabs. Wherein, the winding core group includes a plurality of winding cores 11 , and each winding core 11 has a positive pole lug and a negative pole lug. The connection structure includes a positive connection structure 12 and a negative connection structure (not shown); wherein, the positive connection structure 12 is connected to all positive tabs of the core set; the negative connection structure is connected to all negative tabs of the core set. The tab includes a positive tab 13 and a negative tab 15 ; wherein, the positive tab 13 is connected to the positive connecting structure 12 ; the negative tab 15 is connected to the negative connecting structure.

[0065] The battery provided in this embodiment includes a plurality of winding cores, so that the rate performance of the battery is excell...

Embodiment 2

[0072] Preferably, this embodiment provides a battery, compared with the previous embodiment, such as figure 1 As shown, the present embodiment is further designed as follows:

[0073] In this embodiment, the positive connection structure 12 includes a plurality of positive connection strips, the number of positive connection strips is the same as the number of winding cores 11 in the winding core group, and corresponds to each other; wherein, each positive connection strip has a first part and the second part; and, the first part of each positive connecting strip is connected to the positive tab of the corresponding winding core. Similarly, the negative connection structure includes a plurality of negative connection strips, and the number of negative connection strips is the same as the number of winding cores in the winding core group, and corresponds to each other; wherein, each negative connection strip has a first part and a second part. two parts; and, the first part o...

Embodiment 3

[0079] Preferably, this embodiment provides a battery, compared with the previous embodiment, such as figure 1 As shown, the present embodiment is further designed as follows:

[0080] In this embodiment, one of the positive connection strips in the positive connection structure 12 is the first positive connection strip, and the rest of the positive connection strips are the second positive connection strips; when the second parts of all the positive connection strips are stacked and connected, the first positive connection The second part of the connection belt is located on the side of the positive electrode connection structure away from the winding core group. The positive electrode tab 13 is connected (preferably welded, more preferably ultrasonically welded) to the first positive electrode connecting strip. One of the negative connection strips in the negative connection structure is the first negative connection strip, and the rest of the negative connection strips are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com