Special tool fixture for vertical type combined machining center

A composite machining center and fixture technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the conditions of processing requirements, inability to process, affect processing efficiency and other problems, to expand the processing range, The effect of reducing repeated clamping and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0051] Machine tool used: Pietro Carnaghi (Pietro Carnaghi) 1.6m vertical compound turning and milling machining center.

[0052] Scope of application: medium and large parts with a slewing diameter > 1600m, a clamping height > 170mm, and asymmetrical clamping types.

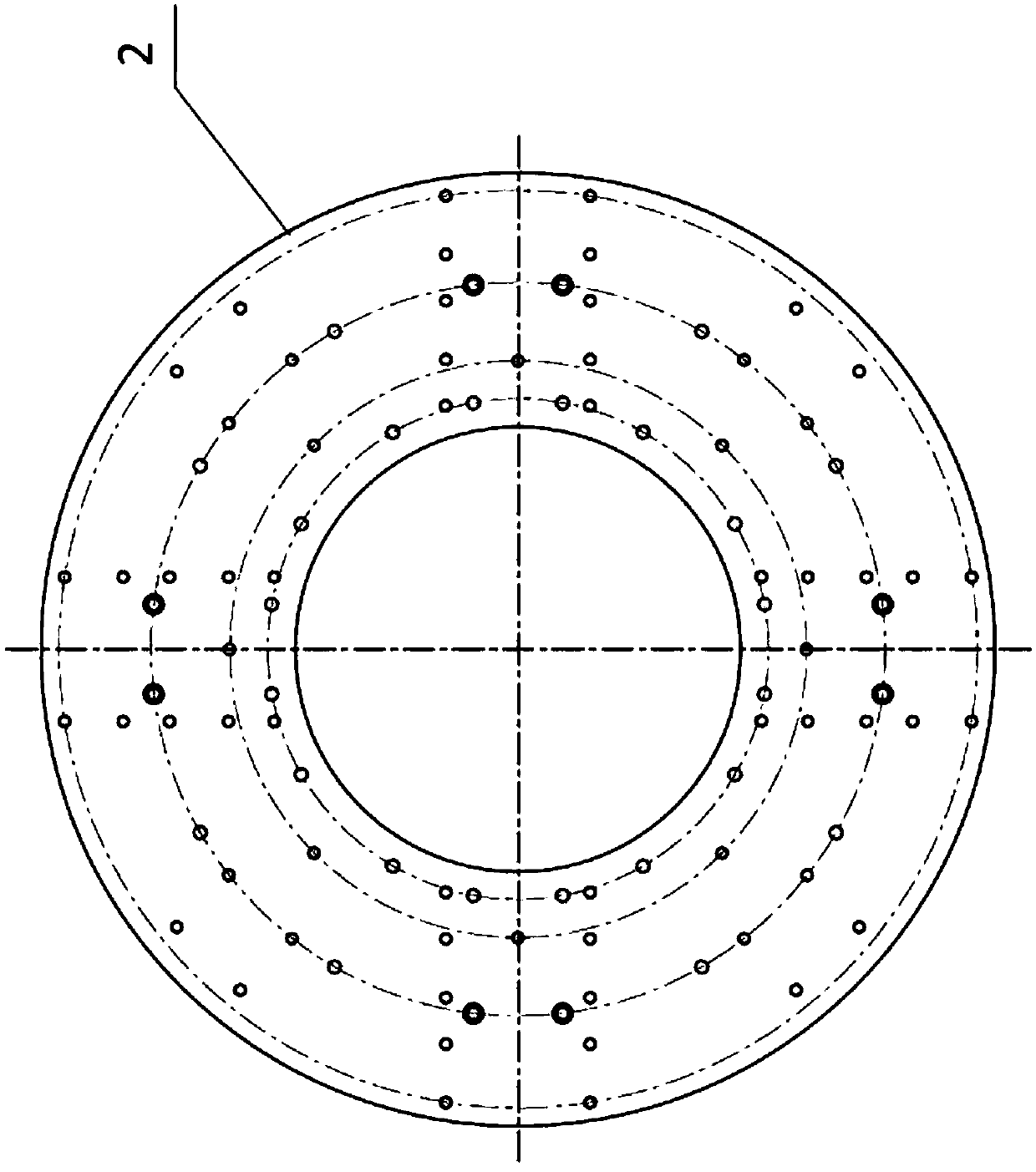

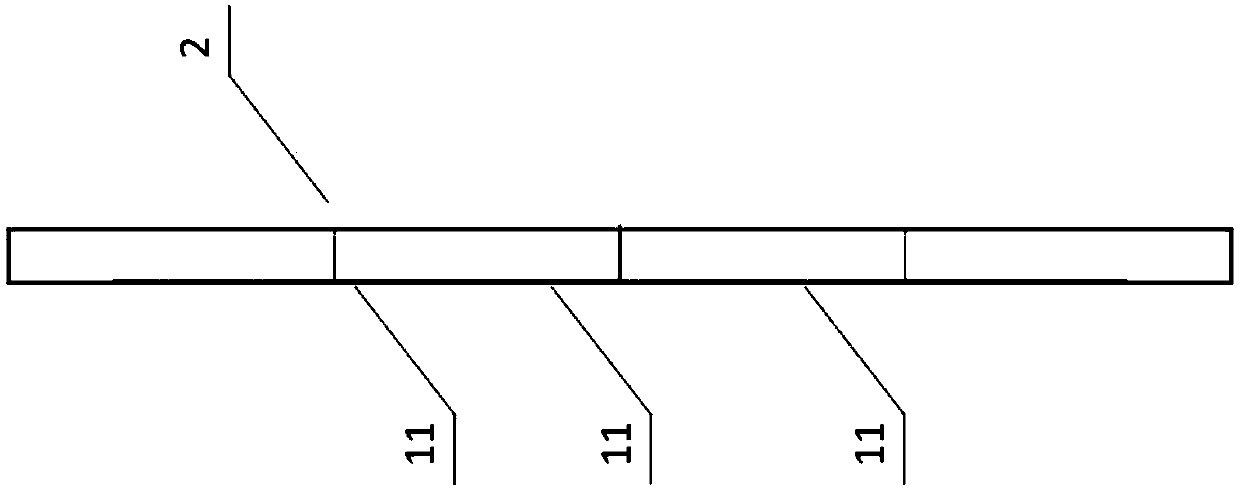

[0053] Processed parts: fixed planet carrier. Fixed planet carrier structure such as Figure 3a and 3b As shown, the rotation diameter of the fixed planet carrier is 1760mm, and the minimum clamping rotation diameter is 1920mm, which is far beyond the working range of the workbench of 1600mm; The connection beam at the place), it is impossible to achieve symmetrical clamping; the coaxiality and position of the parts are required to be high, and there are many processing positions for the hole type, so it is not suitable for repeated clamping.

[0054] Tooling process for fixing the planet carrier:

[0055] (1) Clean the rotary table 9 of the vertical machining center, remove the iron filings on the surface a...

Embodiment 2

[0068] Machine tool used: Pietro Carnaghi (Pietro Carnaghi) 1.6m vertical compound turning and milling machining center.

[0069] Scope of application: medium and large parts with a slewing diameter > 1600m, a clamping height > 170mm, and asymmetrical clamping types.

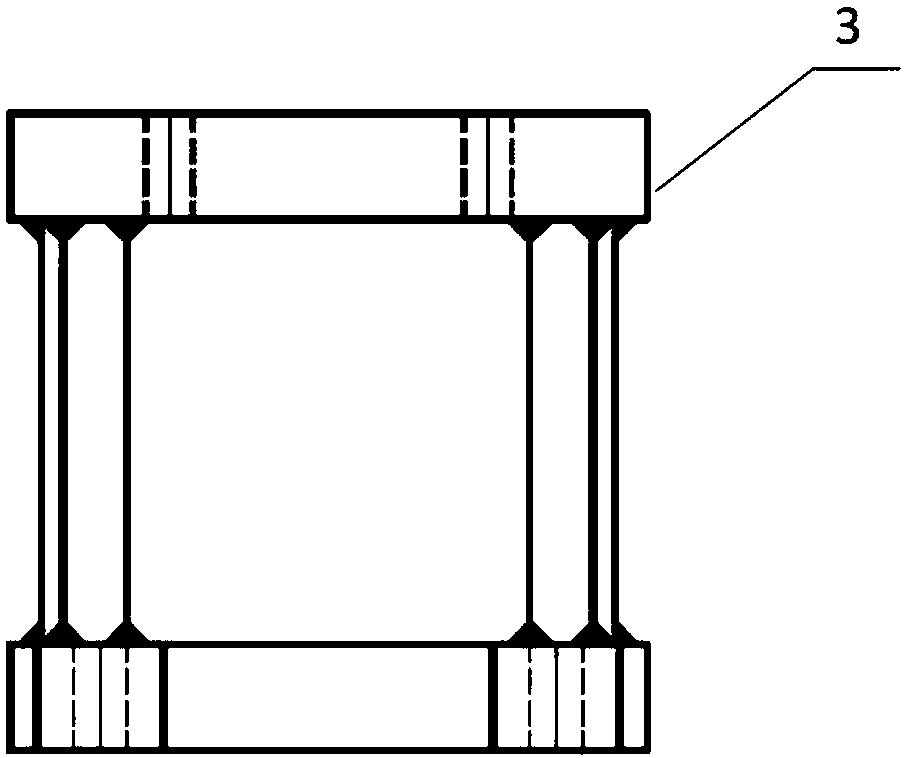

[0070] Machining parts: input planet carrier. Fixed planet carrier structure such as Figure 6a and 6b As shown, the height of the input planet carrier is relatively high, so the clamping height must meet the processing force requirements and should not be too low; Figure 6a As shown, the upper side of the input planet carrier connection (the lower side of the input planet carrier, the far end of the planetary hole) has a non-rotating design, and the theoretical clamping position is the casting surface, which cannot achieve symmetrical clamping, and cannot be used as a secondary clamping The benchmark; the coaxiality and position of the parts have higher requirements, such as Figure 6b The flange faces on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com