Self-regulating cooling machine tool

A machine tool and self-adjusting technology, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of inability to cool the tool, inability to move the spray, and low cooling effect and efficiency, so as to improve the cooling efficiency and the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

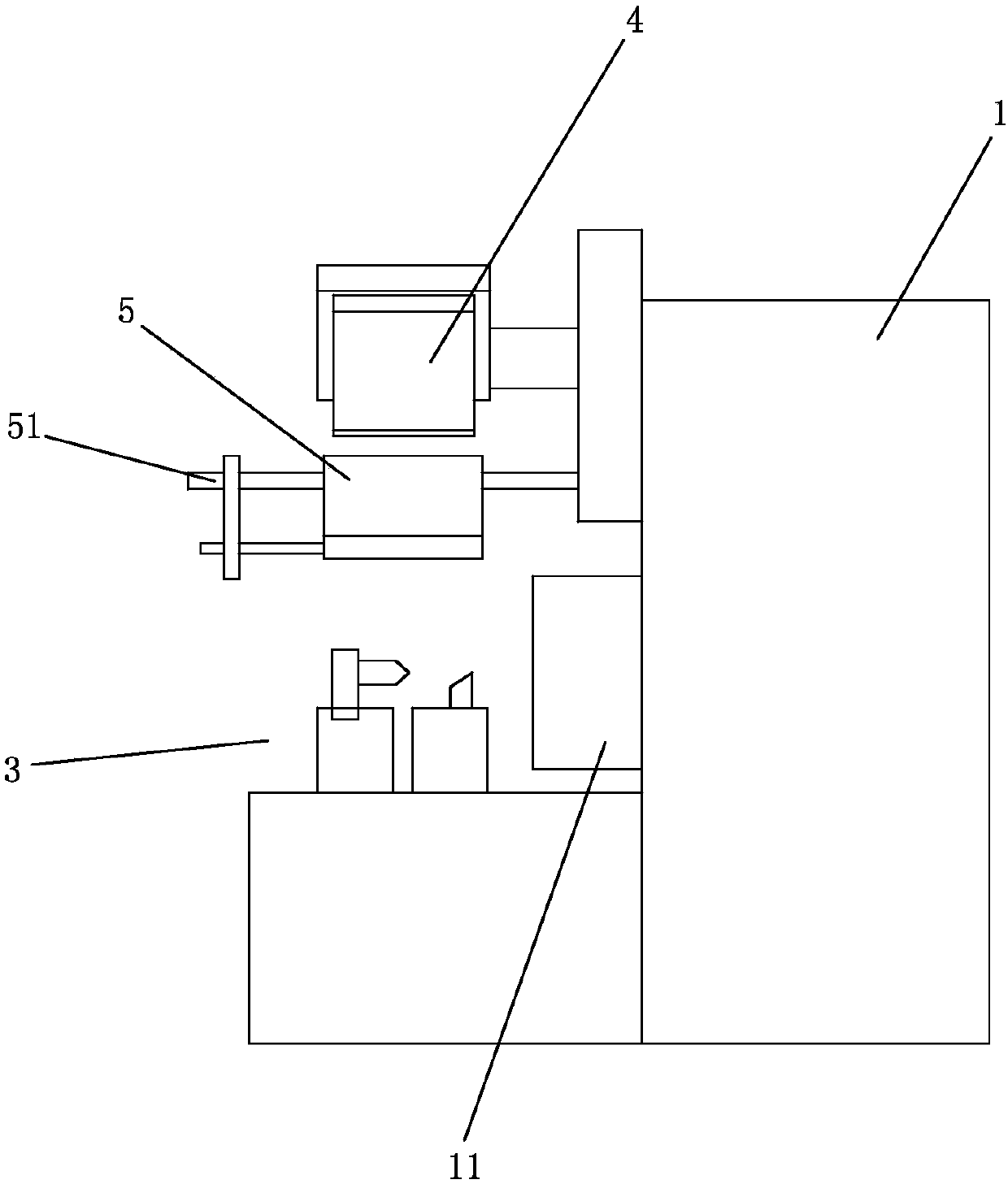

[0010] refer to figure 1 , a self-adjusting cooling machine tool of the present invention, comprising a host 1, the host 1 is provided with a spindle chuck 11 driven by a motor, and a tool 3 that is movable in front of the spindle chuck 11, and the host 1 is placed on the A temperature detection device 4 and a movable cooling spray mechanism 5 are arranged above the tool 3, and the temperature detection device 4 and the cooling spray mechanism 5 are electrically connected.

[0011] As an improvement of the above embodiment, the cooling spray mechanism 5 is installed on a moving frame 51, and the moving frame 51 is connected with a moving mechanism.

[0012] The above is only a preferred embodiment of the present invention, but the present invention is not limited to the above-mentioned embodiments, as long as it achieves the technical effect of the present invention by any same or similar means, it should fall within the protection scope of the present invention .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com