Intelligent mobile operation assembly of wall space polishing machine

A mobile operation and grinding machine technology, applied in machine tools, grinders, grinding/polishing equipment suitable for grinding workpiece planes, etc., can solve the problems of large amount of dust, low efficiency, low level of automation and intelligence, etc. The effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

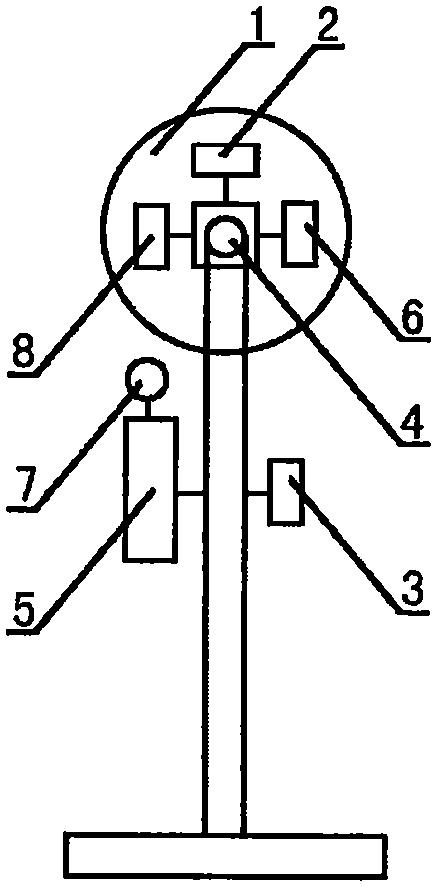

[0012] Embodiment: as shown in the accompanying drawing. The intelligent mobile operation component of the wall grinder includes a body (1), on which a laser displacement sensor (2), a driving device (3), a pressure sensor (4), and a management module (5) are arranged. , the laser displacement sensor (2) is set on the grinding head of the machine body (1) to detect the flatness of the wall surface, the driving device (3) is connected with the management module (5), and is used to drive the grinder for automatic operation. The sensor (4) is arranged between the machine base and the grinding head, and finally the sensed information is controlled and processed by the management module (5).

[0013] The intelligent mobile operation component of the wall grinder is provided with a dust collection device (6) on the body (1), which can absorb dust generated during the operation of the wall grinder.

[0014] The intelligent mobile operation component of the wall grinder is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com