Vacuum insulation board core, vacuum insulation board and refrigerator

A vacuum insulation panel and core material technology, which is applied in heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc., can solve problems such as difficulty in reducing the thickness, weight, and specific gravity of vacuum insulation panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

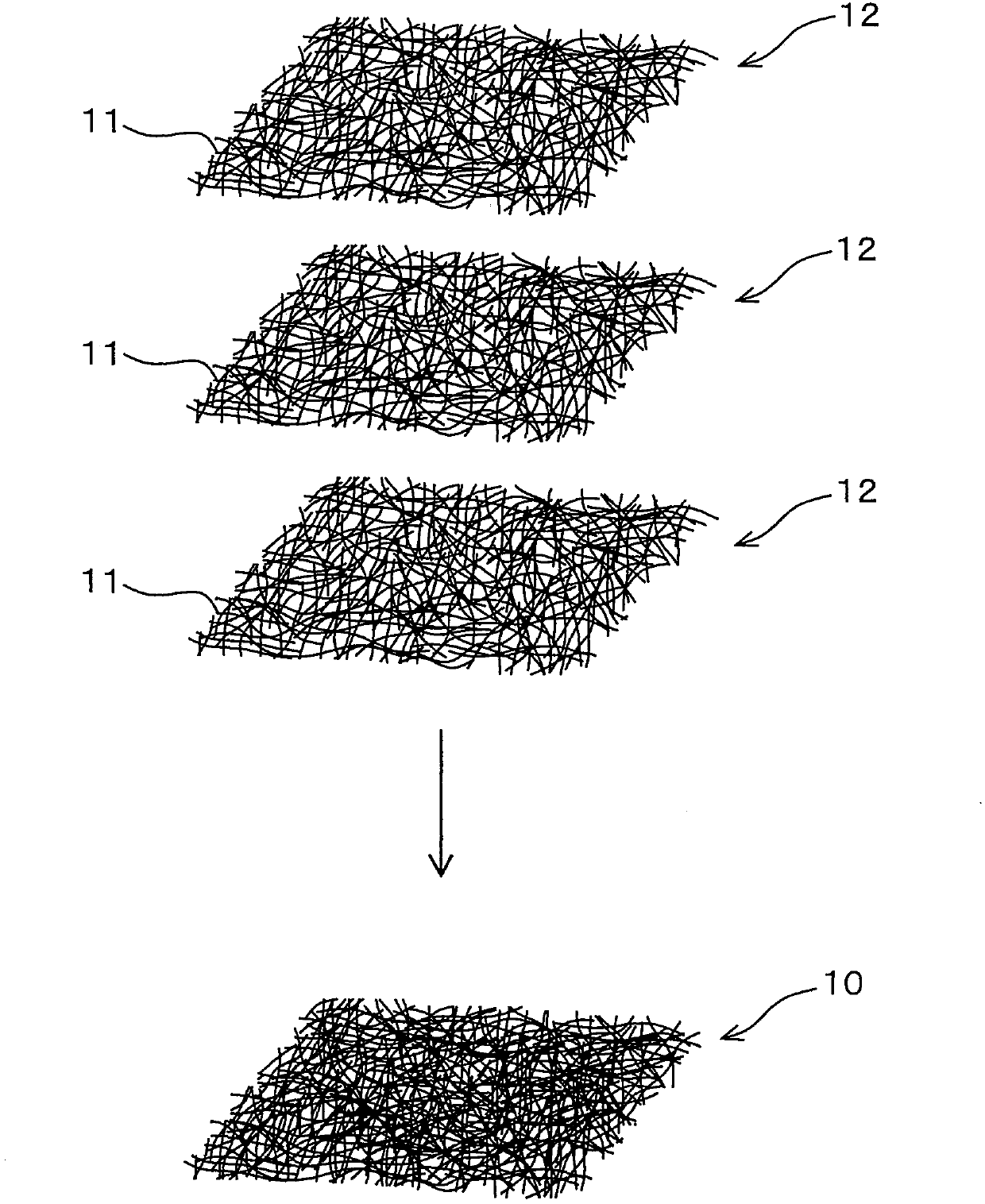

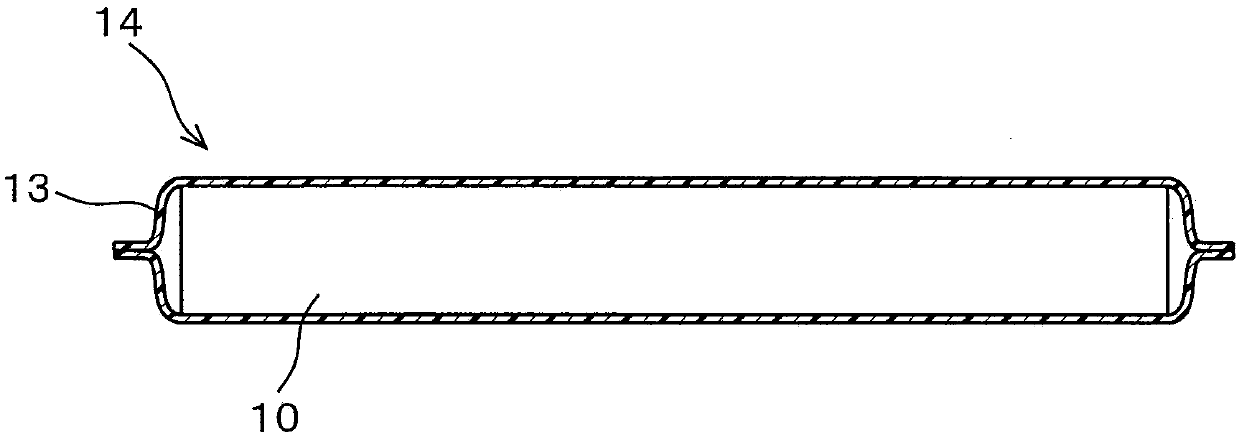

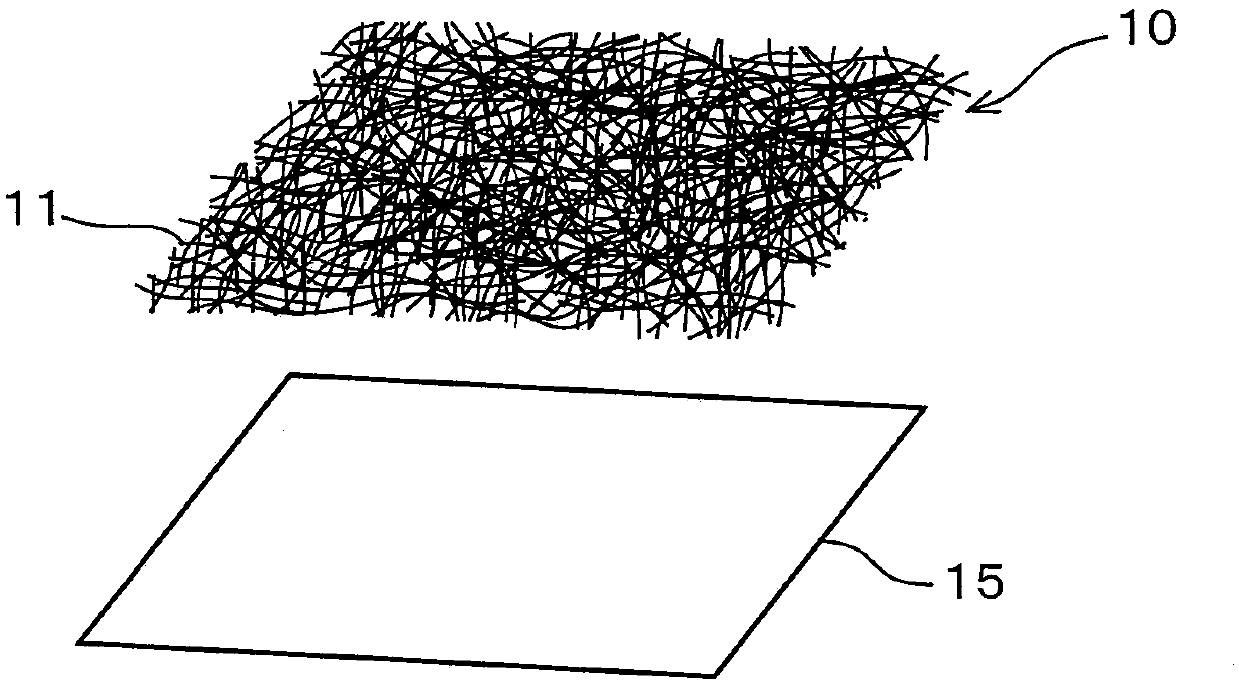

[0048] Examples 1 to 3 used the resin fiber 12 formed by the electrospinning method of this embodiment as the nonwoven fabric 11 constituting the core material 10 . On the other hand, in Comparative Example 1, conventional glass fibers were used for the core material. In addition, in Comparative Example 2, resin fibers 12 were used in the same manner as in Examples 1 to 3 for the core material. In Example 1 and Comparative Example 2, polystyrene (PS) was used as the raw material of the resin fiber 12 . In addition, Example 2 and Example 3 used polyamide-imide (PAI) as the raw material of the resin fiber 12 .

[0049] [resin fiber]

[0050] The density, that is, the specific gravity, of PS which is the raw material of the resin fiber 12 of Example 1 and Comparative Example 2 is 1.05, which is smaller than 2.5 of the glass fiber of Comparative Example 1. In addition, the specific gravity of PAI which is the raw material of the resin fiber 12 of Example 2 and Example 3 is 1.42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com