Mounting and fixing structure for building wall plate and mounting method of mounting and fixing structure

A technology for fixing structures and installation methods, which is applied to building components, building structures, buildings, etc., which can solve the problems of high construction costs, inability to reuse, and large manpower consumption, and achieve shortened preparation time and high mass production efficiency , The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

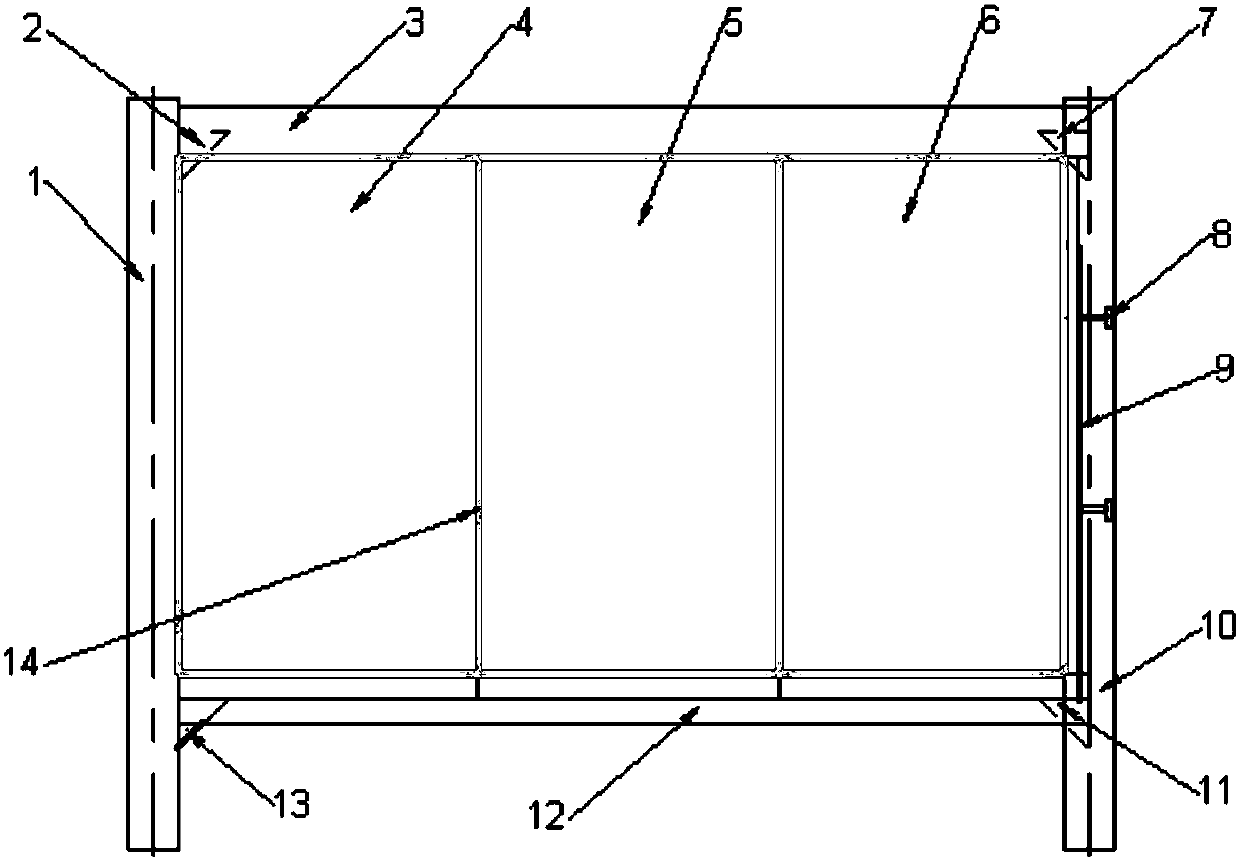

[0071] An installation method for the installation and fixing structure of a building wall panel is specifically:

[0072] 1. Component processing is mass production of backfield machinery and equipment. According to the design requirements, prepare columns, ring beams and other components, and process bolt connection holes and holes for threading and water pipes on them;

[0073] 2. Prefabricate the corbel and process holes for connection with the column and the ring beam;

[0074] 3. Fix the corbel to the column with bolts or direct welding;

[0075] 4. Process composite wall panels, pre-embed threading pipes and cassettes according to architectural design requirements;

[0076] 5. Transport all components, accessories, wall panels, bolts, etc. to the construction site;

[0077] 6. Adjust the orientation of the first column 1 and the second column 10 according to the design requirements, put the lower ring beam 12 on the lower corbels of the first column 1 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com