New load-sensitive balance valve

A technology of load-sensitive and balanced valves, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of large leakage and poor sealing performance, and achieve small pressure loss, stable load movement, and boom motion smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

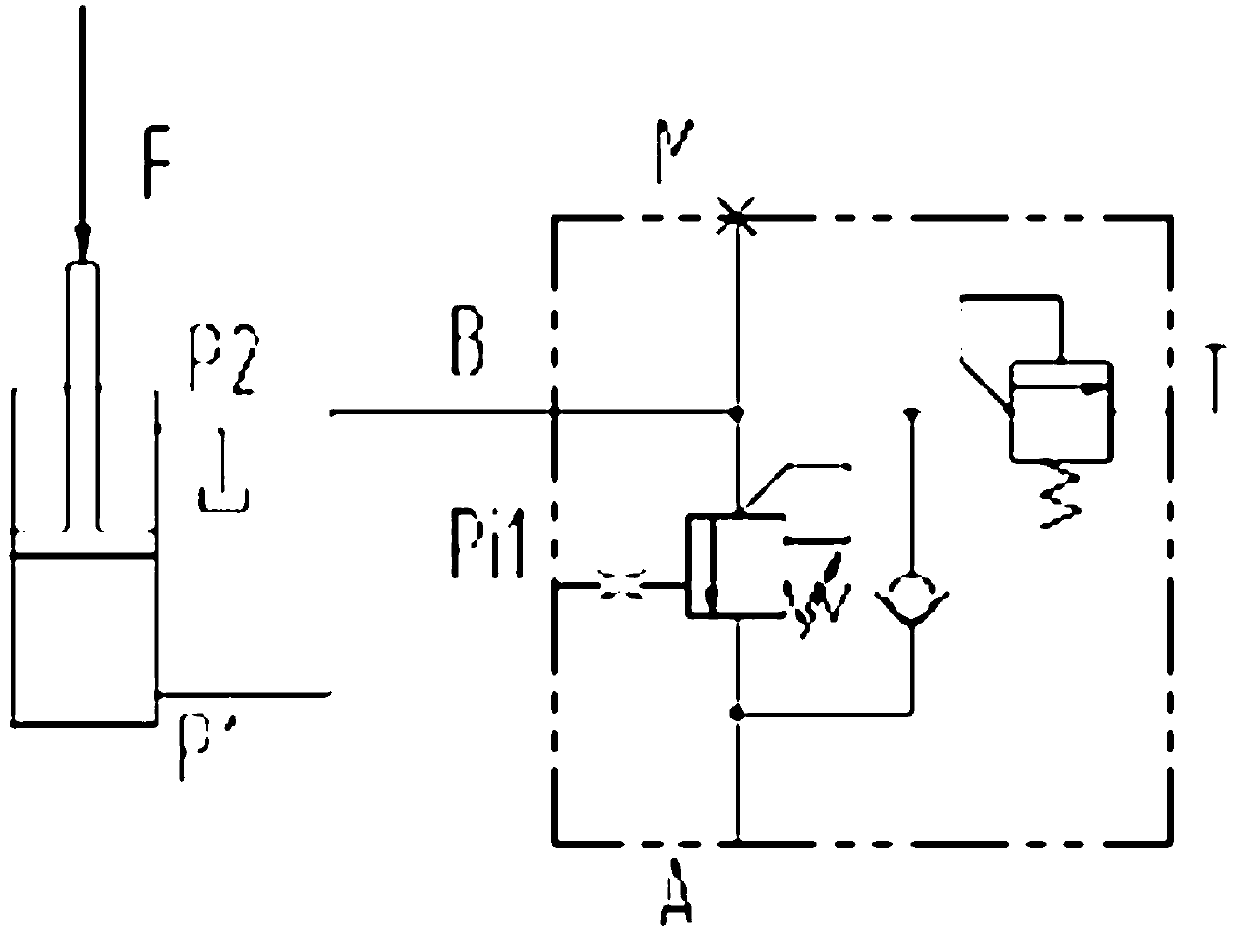

[0012] preferred, such as figure 1 As shown, A is the oil inlet port of the forward channel, B is the load port connected with the hydraulic cylinder, Pil is the pilot port, T is the external drain port, and M is the pressure measuring port. Different from the traditional balance valve, the balance valve introduces the load signal into the side where the spring of the balance valve is located, and the elastic force generated by the spring and the feedback force generated by the load signal act together on the side of the spool to balance the pilot control force and adjust the flow area of the balance valve. In this way, the back pressure is adapted to the load to ensure the smooth movement of the load.

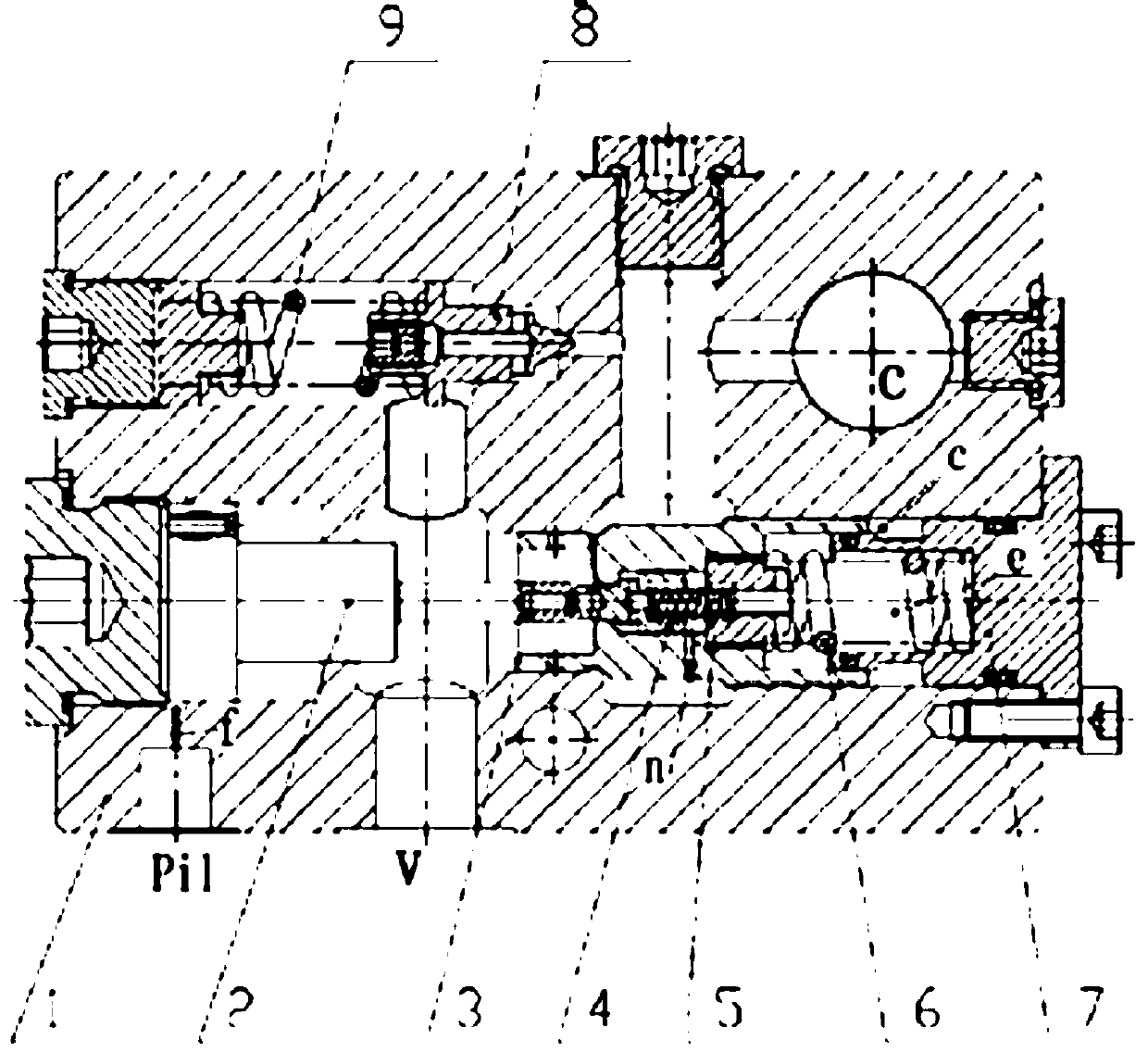

[0013] preferred, such as figure 2 As shown, the balance valve is composed of valve body 1, pilot piston 2, main balance spool 3, small pilot spool 4, overflow spool 8 and other parts and components. The balance valve end cover 7 isolates the load chamber c from the sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com