Prefabricated splice pipe jacking system and construction method thereof

A construction method and jacking technology, applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., can solve the problems of low pipe jacking construction efficiency and low precision, and achieve fast construction speed and high processing efficiency. , the effect of excellent process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

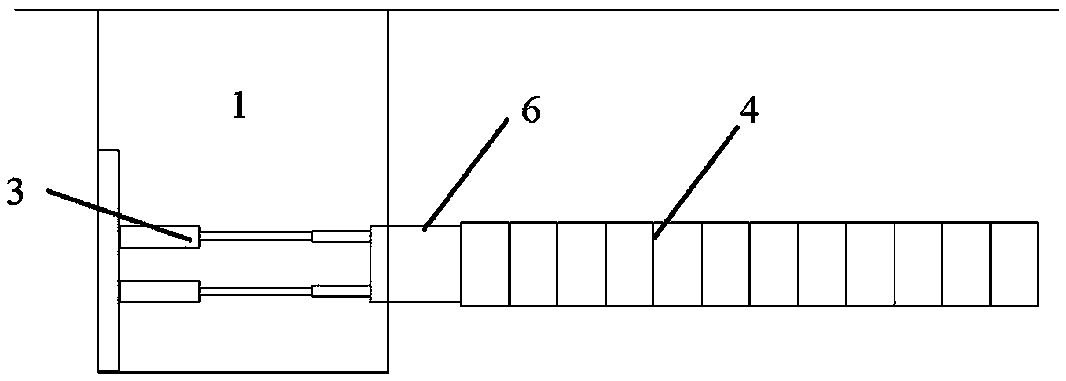

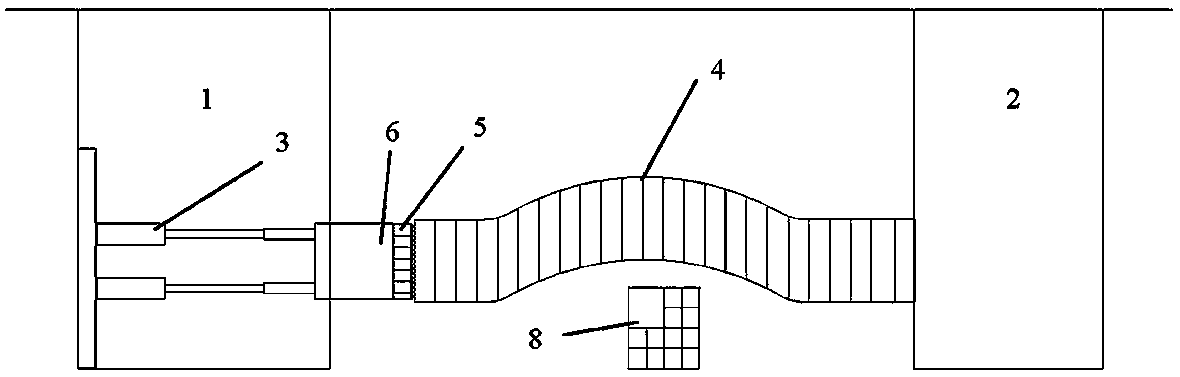

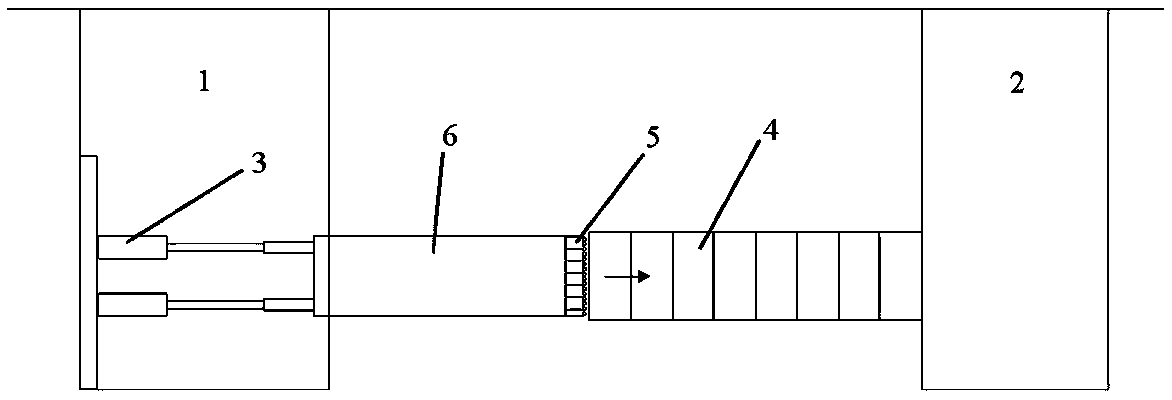

[0068] Examples see figure 1 As shown, this prefabricated spliced pipe fitting jacking system includes the main jacking mechanism 3, and also includes spliced pipes arranged along the design path of the designed pipe 6, the inner diameter of the spliced pipe is larger than the outer diameter of the designed pipe 6, and the spliced pipe is formed by The splicing pipe fittings 4 are spliced together.

[0069] see Figure 5 As mentioned above, the splicing pipe fitting 4 is a strip plate, and its front and rear sides respectively protrude outward to form an axial overlapping edge, and the left and right sides respectively protrude outward to form a circumferential overlapping edge; see Figure 4 As shown, the coaxial splicing pipe fittings 4 are sequentially spliced along the axial direction of the splicing pipe through the axial overlapping edges and fastened by the connecting piece 7, and the splicing pipe fittings 4 of the same circumference pass through the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com