Air source heat pump system and control method thereof

An air source heat pump and control method technology, applied in the field of heat pumps, can solve the problems of inability to evaporate liquid working medium, liquid in the suction of the compressor, and inability to continue heating, etc., to achieve the effects of enhanced condensation effect, increased energy, and faster time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

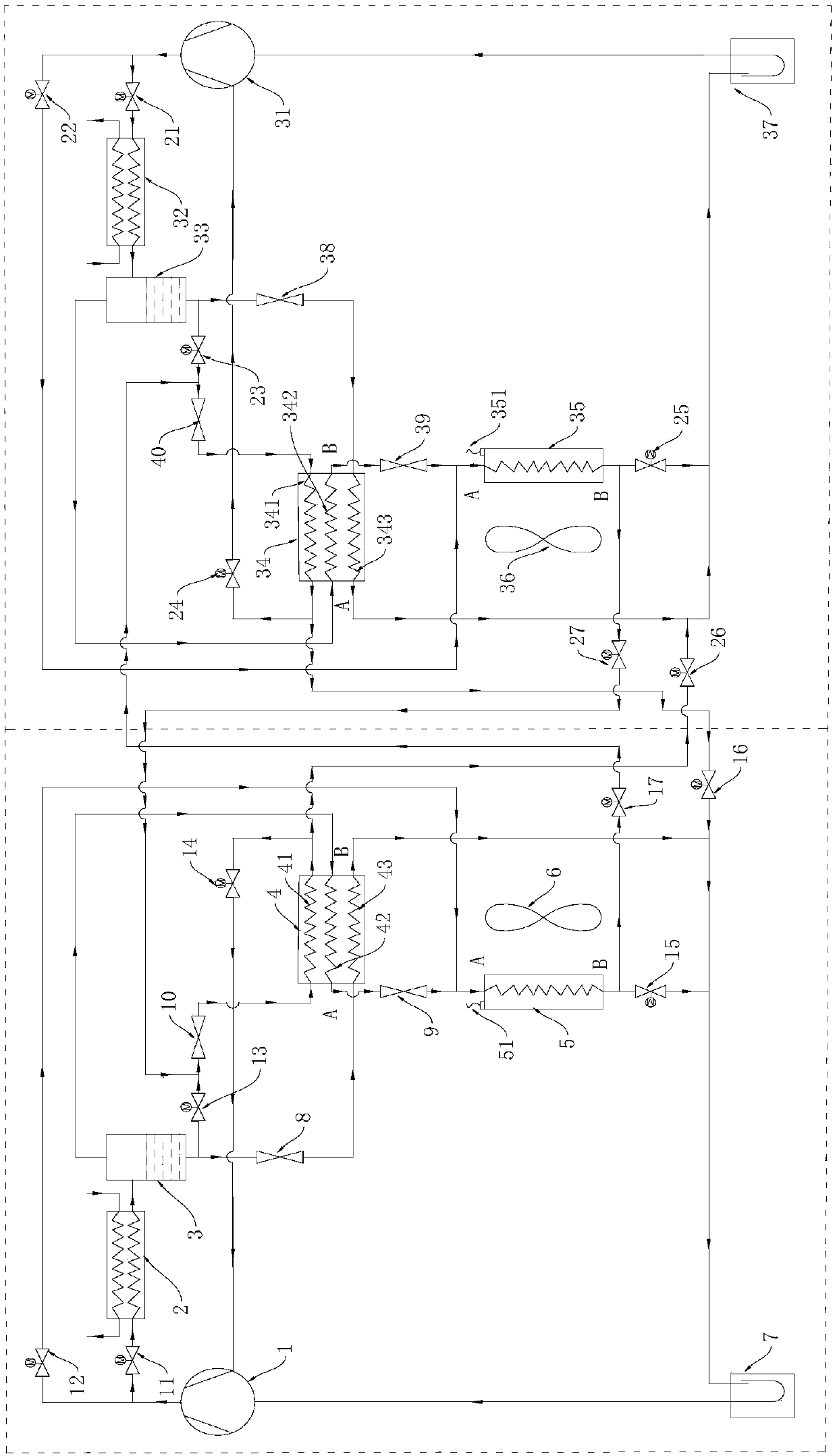

[0024] Such as figure 1As shown, according to the system diagram of the air source heat pump system of the present invention, an air source heat pump system is proposed in an embodiment of the present invention, and the air source heat pump system may include: a first subsystem and a second subsystem; A subsystem includes: a first compressor 1, a first condenser 2, a first gas-liquid separator 3, a first heat exchanger 4, a first throttle valve 8, a second throttle valve 9, and a first evaporator 5; The second subsystem includes: the second compressor 31, the second condenser 32, the second gas-liquid separator 33, the second heat exchanger 34, the fourth throttle valve 38, the fifth throttle valve 39, the second Six throttling valves 40, the second evaporator 35; the first condenser 2 can communicate with the outlet end of the first compressor 1, the inl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap