Inverted metal detection probe

A metal detection, inverted technology, applied in measuring devices, electrical/magnetic exploration, geophysical measurement, etc., can solve the problems of poor anti-electromagnetic interference, low sensitivity, difficult synchronization, etc., and achieve strong anti-electromagnetic interference ability. , the effect of strengthening environmental noise recognition and increasing product sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

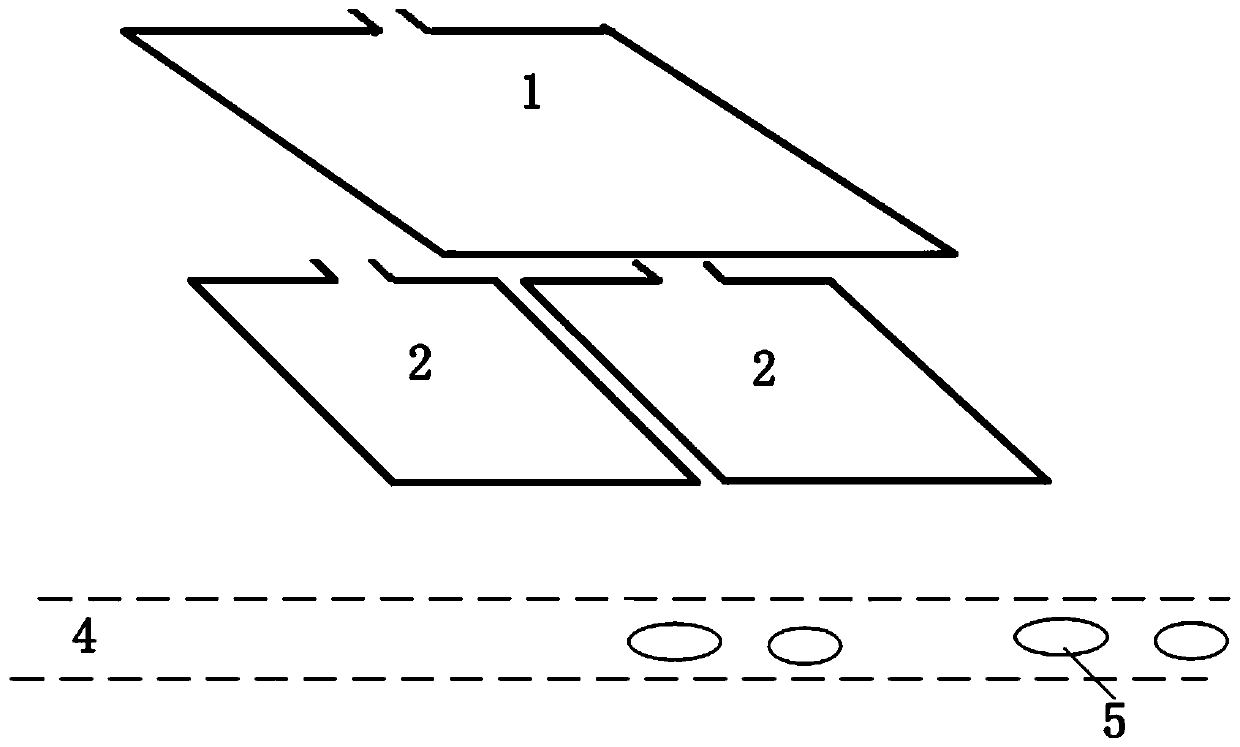

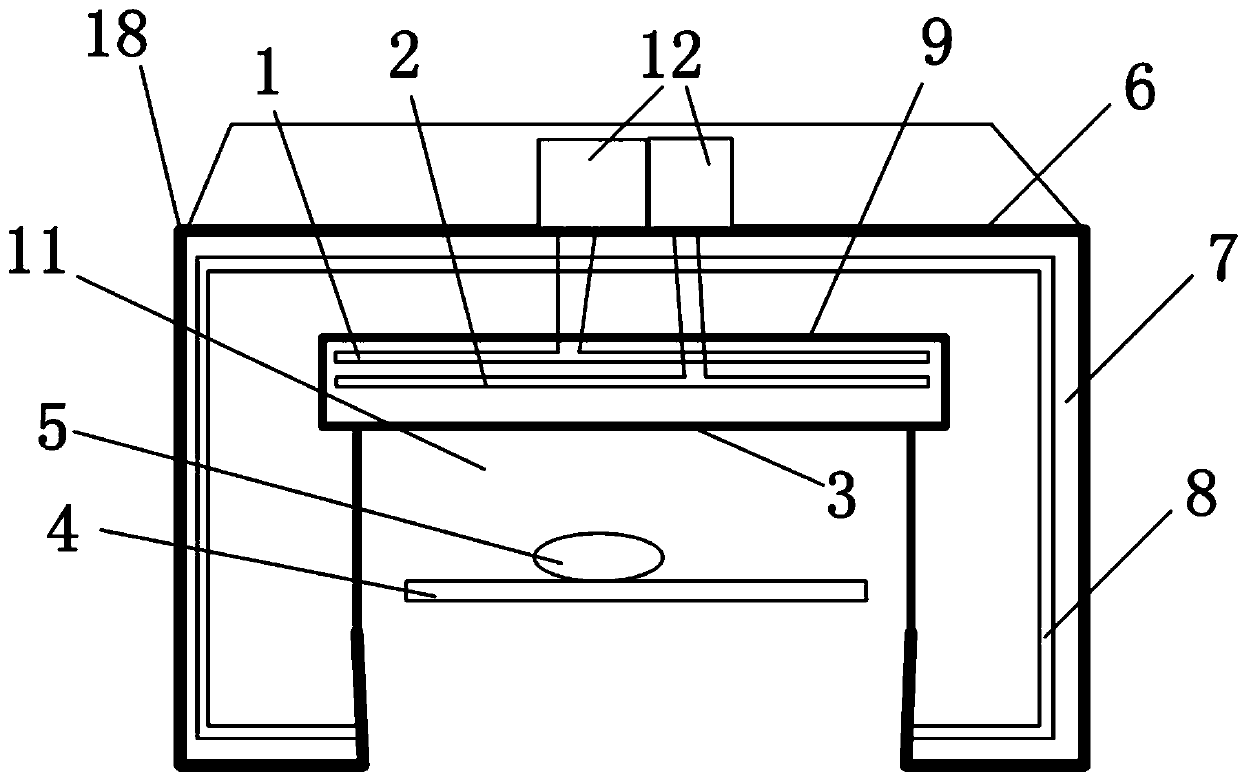

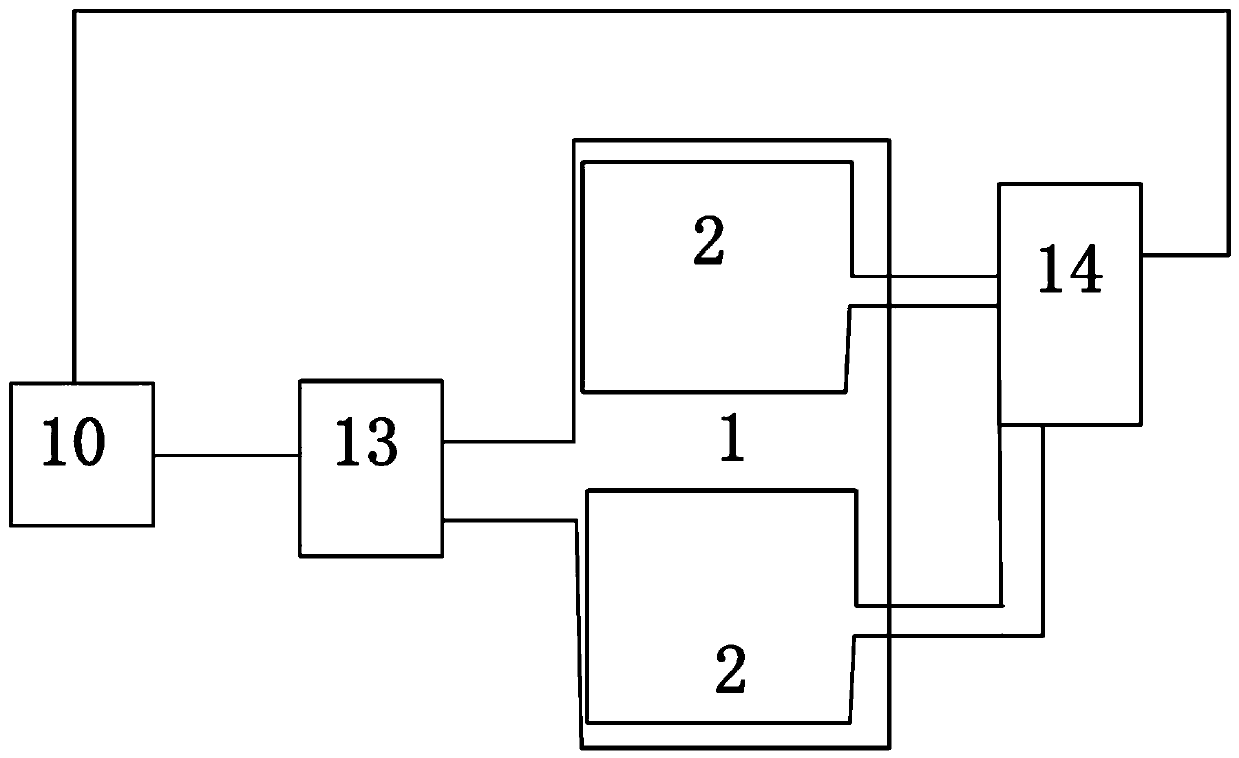

[0031] like Figure 1-4 Shown, a kind of upside-down metal detection probe, described probe is a gantry-shaped detection frame; The lower channel of the gantry-shaped detection frame is the detection channel 11; A detection module is arranged in the gantry-shaped detection frame; The detection module includes The protective shell 6, the main control module 10, the driving circuit 13, the transmitting coil 1, the receiving coil 2 and the receiving circuit 14; the receiving coils 2 are an even number, and each receiving coil 2 has the same specification and is located above the detection channel 11; Each receiving coil 2 is parallel to the detection channel 11; the transmitting coil 1 is located above and parallel to each receiving coil 2; each receiving coil is arranged symmetrically above the detection channel with the center point of the transmitting coil arrangement position as a symmetrical point.

[0032] The number of the transmitting coil is one, and each receiving coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com