Electromagnetic compatibility experimental method for industrial robot controllers

An industrial robot and electromagnetic compatibility technology, applied in the field of servo drive, can solve problems such as limiting the stability and reliability of servo drive equipment, interference of controller equipment hardware and software systems, breakdown failure of capacitors, control chip equipment, etc., to achieve Improve the efficiency and accuracy of detection operations, facilitate the acquisition of detection data, and reduce the cost and labor intensity of detection operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

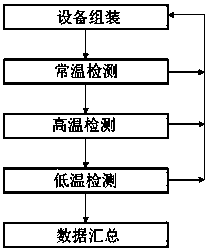

[0022] like figure 1 An electromagnetic compatibility experiment method for an industrial robot controller is shown, comprising the following steps:

[0023]The first step is to assemble the equipment. The first step is to assemble the equipment. First, install at least two controllers to be tested on the testing equipment. Each controller is connected to an industrial robot servo drive system, and each servo drive system is separately The loads matching their rated power are connected to each other, and then the controller to be tested is wrapped in the same closed space with a sealed protective cover, and then at least two electromagnetic radiation sources, at least one hot air blower and at least one Cooling fan, and each electromagnetic radiation source, hot air blower and cooling fan are evenly distributed around each controller to be tested, wherein the axis of the electromagnetic radiation source and the surface of the controller to be tested are at an angle of 90°, and...

Embodiment 2

[0032] like figure 1 As shown, an electromagnetic compatibility experiment method for an industrial robot controller includes the following steps:

[0033] The first step is to assemble the equipment. The first step is to assemble the equipment. First, install at least two controllers to be tested on the testing equipment. Each controller is connected to an industrial robot servo drive system, and each servo drive system is separately The loads matching their rated power are connected to each other, and then the controller to be tested is wrapped in the same closed space with a sealed protective cover, and then at least two electromagnetic radiation sources, at least one hot air blower and at least one Cooling fan, and each electromagnetic radiation source, hot air blower and cooling fan are evenly distributed around each controller to be tested, wherein the axis of the electromagnetic radiation source and the surface of the controller to be tested are at an angle of 45°, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com