a medical guide wire

A guide wire and helical groove technology, applied in the field of medical equipment, can solve the problems such as the inability to adjust the flexibility, hardness and bending degree of the guide wire, and the inability to adjust and use it, so as to achieve good controllability and pushing force, convenient guide wire, Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

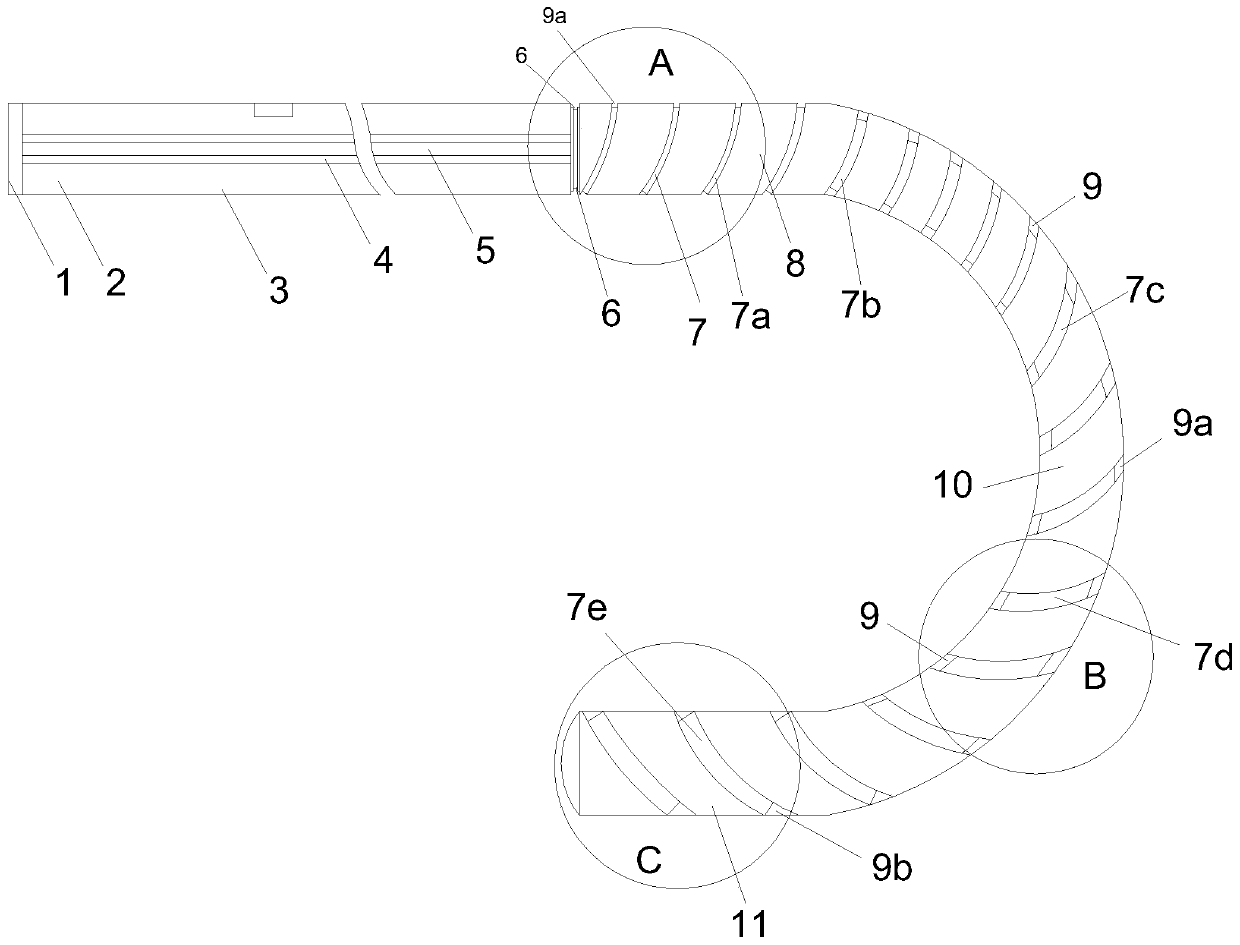

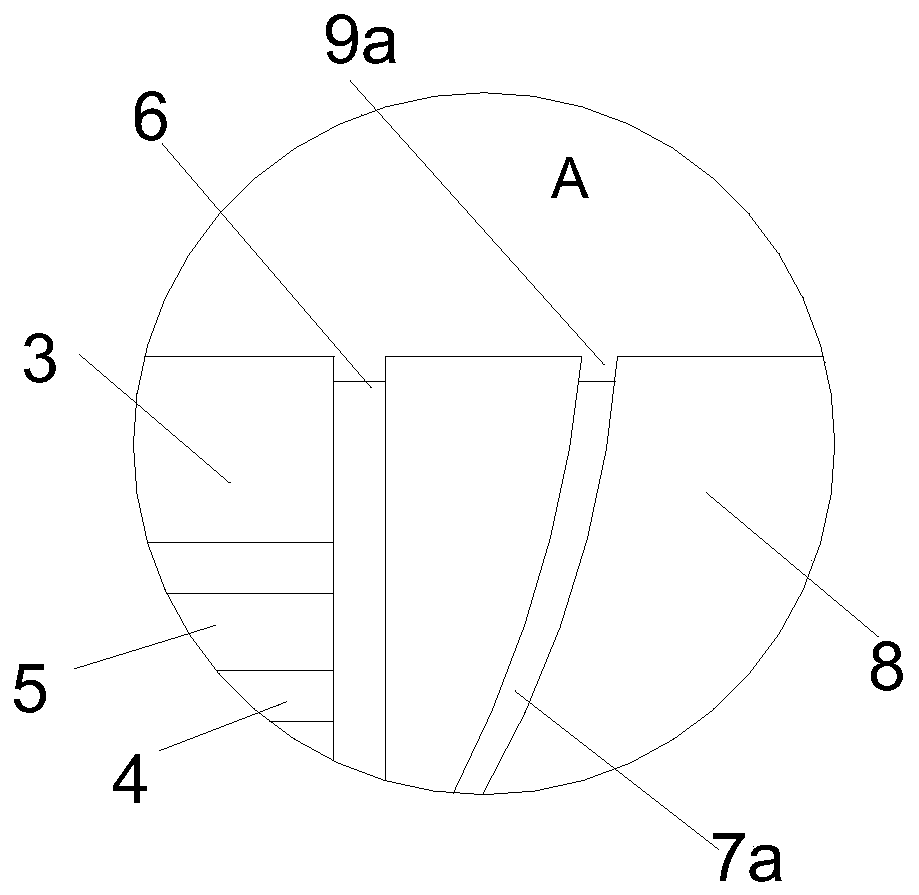

[0031] Such as Figure 1 to Figure 4 As shown, the present invention provides a medical guide wire, the outer diameter of the guide wire is in the range of 0.60mm-0.80mm, the preferred outer diameter is 0.6mm, 0.65mm or 0.80mm, and the medical guide wire includes a metal inner core 3 and the resin layer arranged on its outer layer, and one end of the inner core 3 is provided with a connection part 1 for rigid connection with other guide wires of different materials and hardness. The guide wire is preferably made of stainless steel or nickel-titanium alloy, and superelastic alloys such as Ni-Ti alloy are the best options. The bending radius R of the curved flexible front end of the medical guide wire can range from 0.2 mm to 20 mm, and preferably range from 10 mm to 15 mm. Generally, the length of the front end of the curved portion may be 5mm-40mm, preferably 10mm-30mm. The length range of the guide wire is preferably between 100cm-450cm, and more preferably between 300cm-40...

Embodiment 2

[0033] This embodiment is further improved on the basis of Embodiment 1, the difference is:

[0034] Such as Figure 5 , 6 As shown, the medical guide wire provided by the present invention implements another preferred technical solution, specifically, the bottom of the first positioning groove 9a is provided with a third positioning groove 9c whose width is smaller than that of the first positioning groove 9a, and the third positioning groove 9a The positioning grooves 9c are arranged at the front ends of the head portion 8 and the arc portion 10, and the two third positioning grooves 9c are arranged opposite to each other.

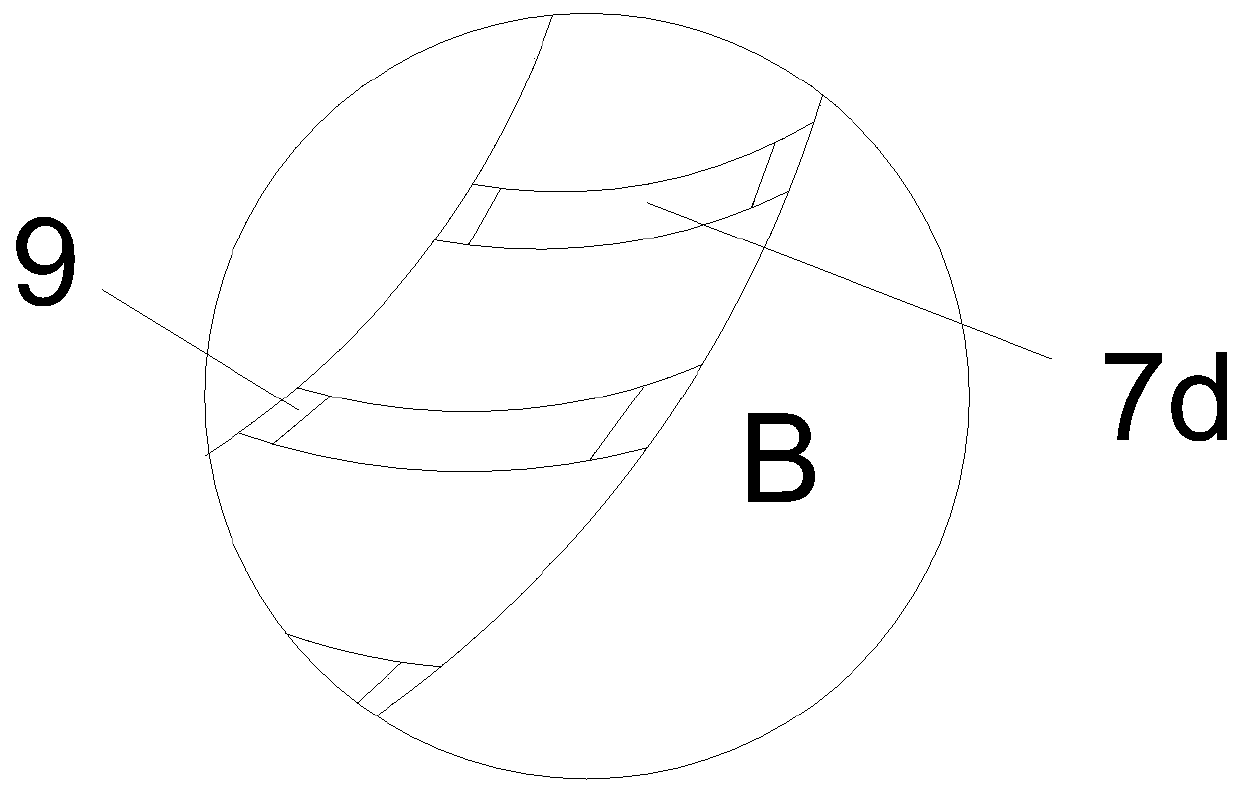

[0035] Such as Figure 7 As shown, the fourth positioning groove 9d and / or the fifth positioning groove 9e with a rectangular cross section are provided at the middle end of the arc portion 10, and the fourth positioning groove 9d and / or the fifth positioning groove 9e are oppositely arranged and Misplacement setting, the fourth positioning groove 9d ...

Embodiment 3

[0038]The present invention also provides a spring used in conjunction with a medical guide wire, and the structure of the spring is set corresponding to the structure of the medical guide wire provided in embodiment 1 or embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com