Machining method for thin-wall shaft sleeve with two ends supported and middle suspended

A processing method and technology for thin-walled shafts, which are applied in the field of aero-engine assembly and processing, can solve the problems of the precise outer diameter of the bushing, the scrapped cylindricity, and the deformation of the bushing, so as to solve the problems of scrapped processing, high processing efficiency and high cost performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

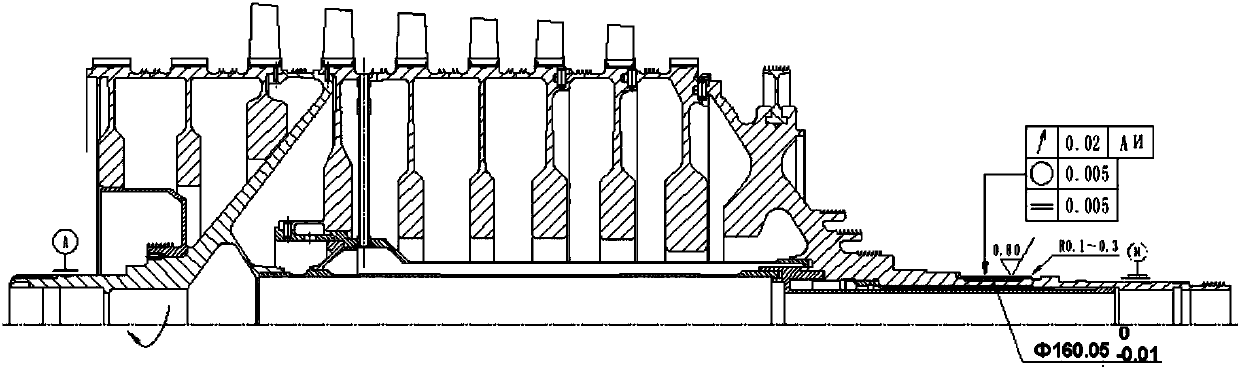

[0034] 1) Installation and alignment: Install the rotor on the horizontal lathe, and the front and rear journals of the alignment rotor run out no more than 0.01mm.

[0035] 2) Rough turning: For the material of the parts of the thin-walled bush, select the corresponding machine-added blade material and R, rough turn the outer circle of the bush, and leave a margin of 0.10-0.15mm on one side.

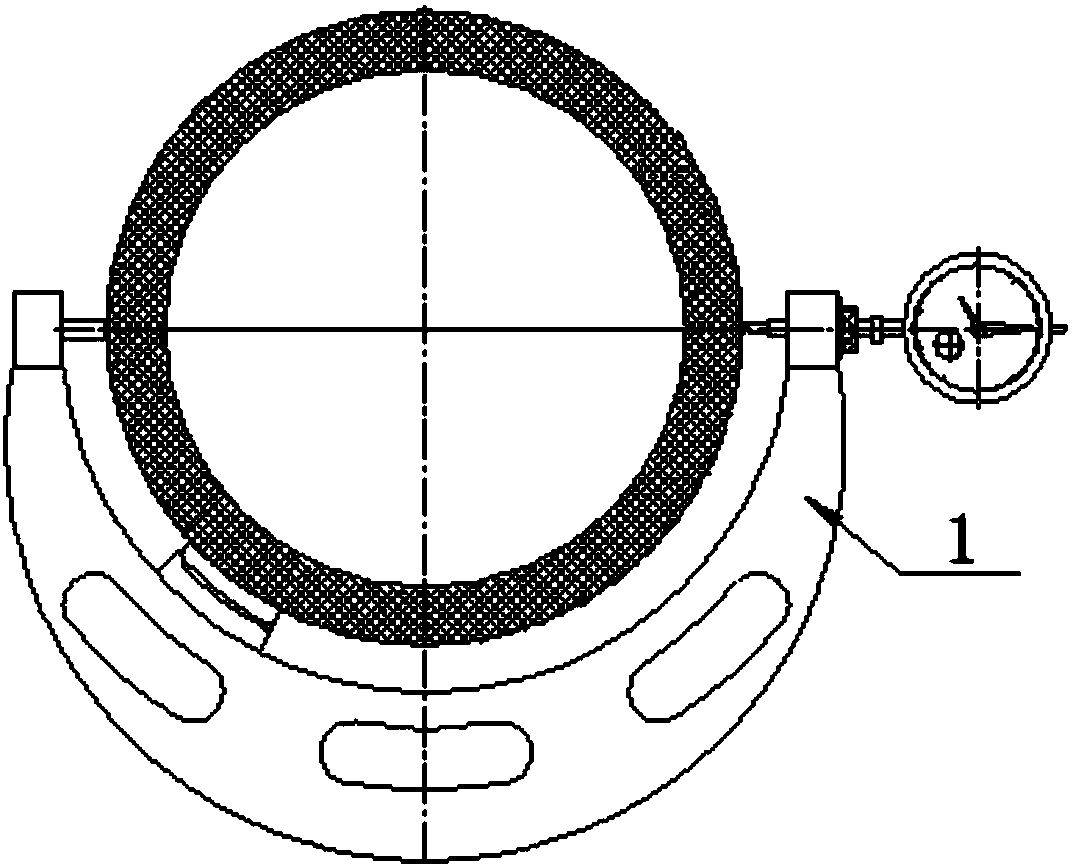

[0036] 3) Finish turning: The runout of the front and rear journals of the rotor is not greater than 0.01, the outer circle of the bushing is finished, the blade number is VBGT160401-F1CP500, and the feed rate is within 0.018-0.032. After each cut, it is on the outer circle of the bushing Draw the grid with a marker pen, measure 6 sections in detail, and measure the outer diameter value of 8 points for each section, leaving a margin of 0.015mm on one side of the smallest diameter.

[0037] 4) Chamfering: 0.2-0.4mm chamfering on the sharp edge of the shaft sleeve.

[0038] 5) Inspection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com