Intelligent cutting tool detection system

A detection system and tool technology, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problem that the tip of the tool cannot be detected in time, the tip or edge of the tool is broken, the tool holder and the tool seat and Machine tool damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the various embodiments shown in the accompanying drawings, but it should be noted that these embodiments do not limit the present invention. Equivalent transformations or substitutions all fall within the protection scope of the present invention.

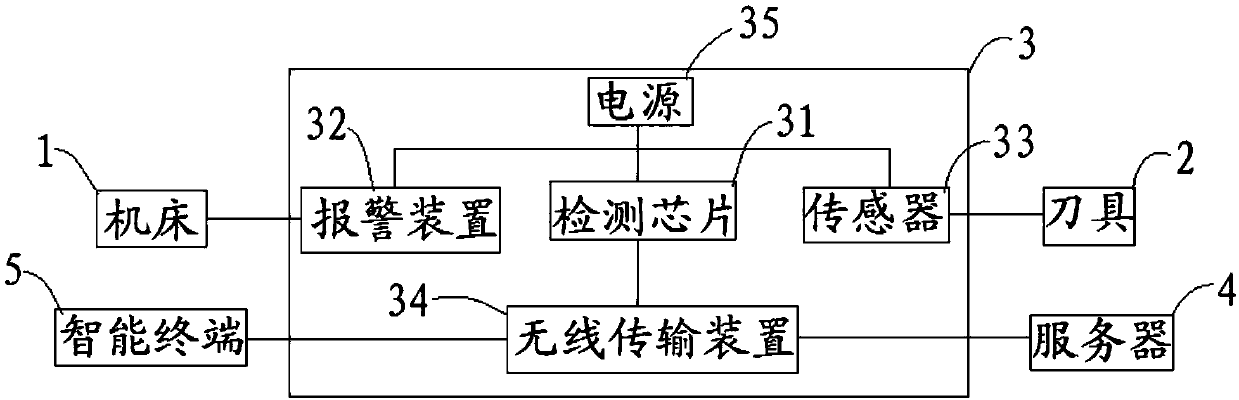

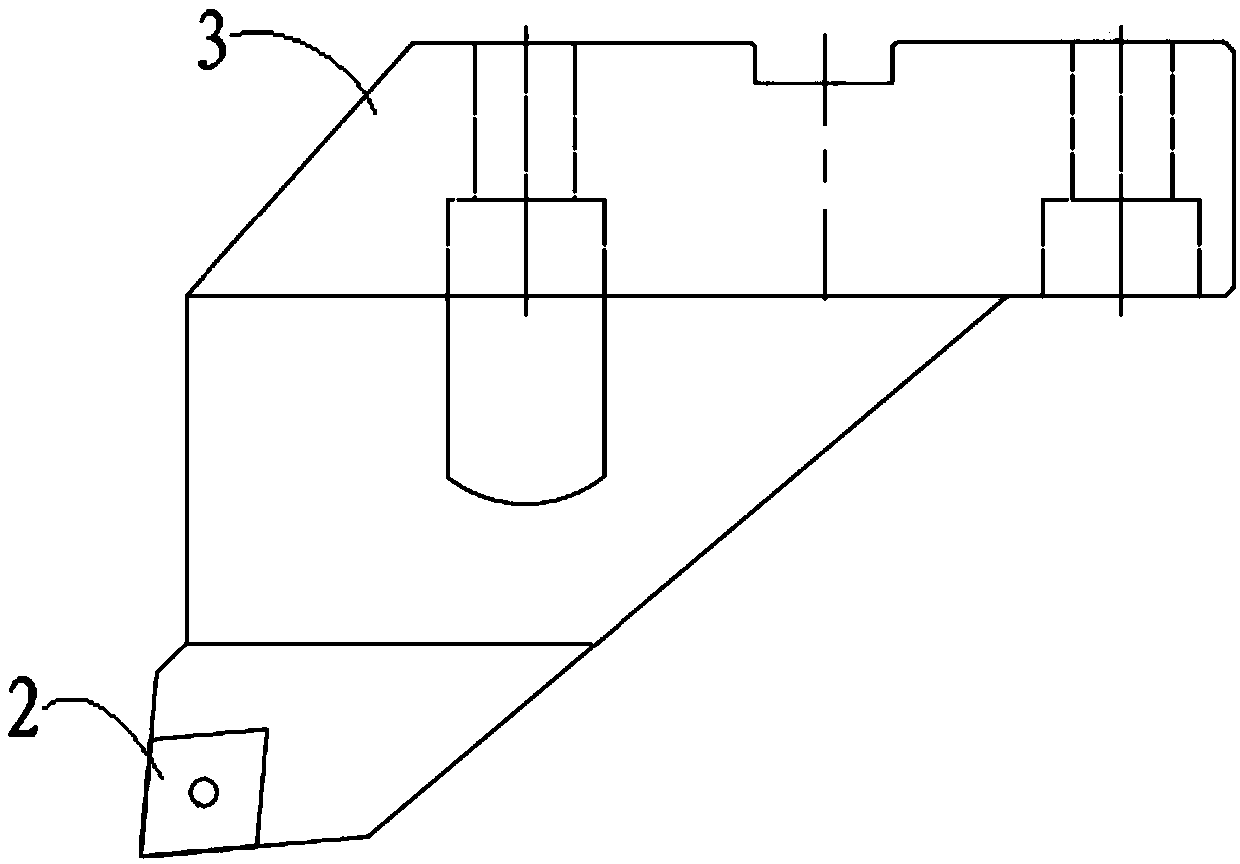

[0022] like figure 1 , 2 As shown, the intelligent tool detection system of the present invention includes: a machine tool 1 , a tool 2 , a tool holder 3 and a server 4 .

[0023] The tool holder 3 is installed on the machine tool 1 , and is used to realize the installation of the tool 2 on the machine tool 1 and the basic detection of the cutting force and the degree of wear of the tool 2 . The tool seat 3 is provided with a mounting slot for the tool 2 to be installed, and a machine tool connection bolt hole connected with the machine tool 1 . Therefore, the tool 2 is mounted on the machine tool 1 through the tool holder 3 to process the parts. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap