Light-transmitting light-storing self-luminous surface layer material used for water permeable roads in sponge city and preparation method of surface layer material

A technology of sponge city and surface layer material, which is applied in the directions of roads, roads, road indicators, etc., can solve the problems that the functions of luminous powder cannot be fully exerted, and the surface layer of permeable roads cannot take into account the water permeability and luminous performance, so as to save roads. The effect of lighting energy consumption, good decorative effect and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

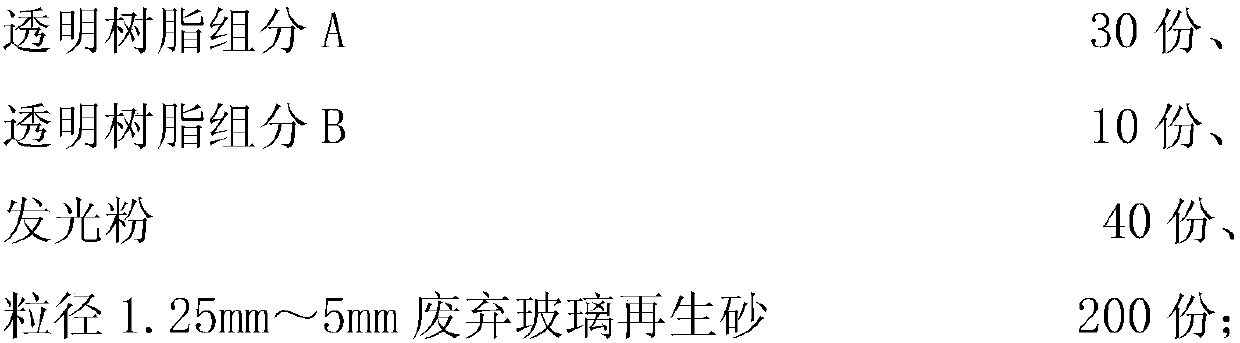

[0039] A light-transmitting light-storage self-luminous surface layer material for permeable roads in sponge cities, which consists of the following components and raw materials in parts by weight:

[0040]

[0041] The preparation method of the light-transmitting light-storing self-luminous surface layer material for the sponge city permeable road is as follows:

[0042] 1) According to the ratio of 30 parts by weight of transparent resin component A, 10 parts by weight of transparent resin component B, 40 parts by weight of luminescent powder and 200 parts by weight of 1.25mm-5mm waste glass reclaimed sand, the raw materials of each component are taken ;

[0043] 2) Mix the transparent resin A component and the transparent resin B component uniformly first, then add the luminescent powder and waste glass regenerated sand in sequence, and stir evenly to obtain a bulk premix;

[0044] 3) Pour the bulk premix into steel molds or on the surface of dry permeable concrete, per...

Embodiment 2

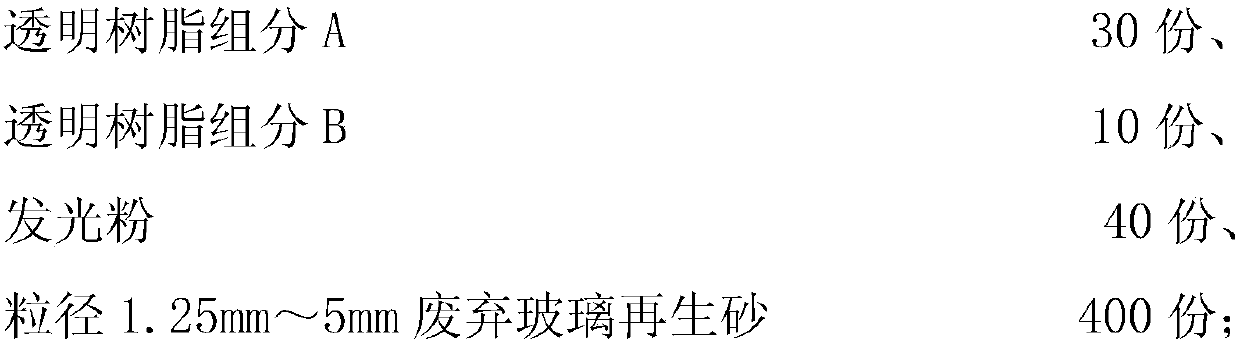

[0047] A light-transmitting light-storage self-luminous surface layer material for permeable roads in sponge cities, which consists of the following components and raw materials in parts by weight:

[0048]

[0049] The preparation method of the light-transmitting light-storing self-luminous surface material for the permeable road of the sponge city is as follows:

[0050] 1) According to the ratio of 30 parts by weight of transparent resin component A, 10 parts by weight of transparent resin component B, 40 parts by weight of luminescent powder and 400 parts by weight of 1.25mm-5mm waste glass reclaimed sand, the raw materials of each component are taken ;

[0051] 2) Mix the transparent resin A component and the transparent resin B component uniformly first, then add the luminescent powder and waste glass regenerated sand in sequence, and stir evenly to obtain a bulk premix;

[0052] 3) Pour the bulk premix into steel molds or on the surface of dry permeable concrete, pe...

Embodiment 3

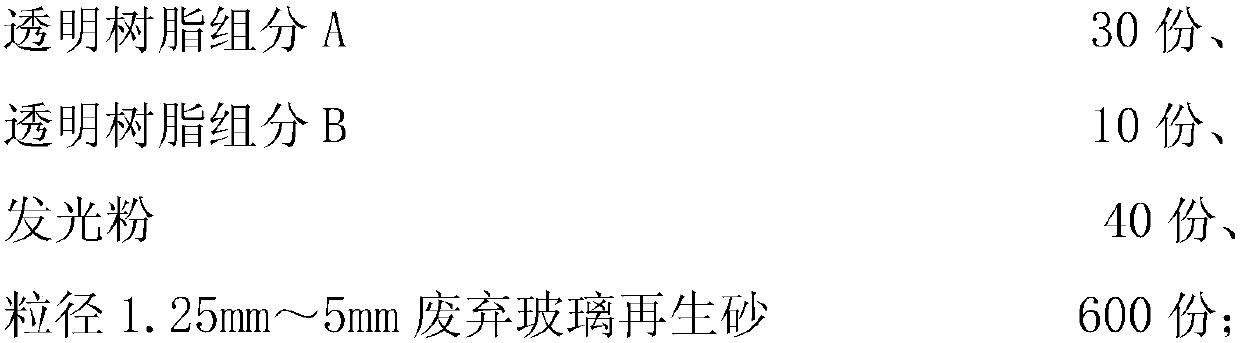

[0055] A light-transmitting light-storage self-luminous surface layer material for permeable roads in sponge cities, which consists of the following components and raw materials in parts by weight:

[0056]

[0057] The preparation method of the light-transmitting light-storing self-luminous surface material for the permeable road of the sponge city is as follows:

[0058] 1) According to the ratio of 30 parts by weight of transparent resin component A, 10 parts by weight of transparent resin component B, 40 parts by weight of luminescent powder and 600 parts by weight of 1.25mm-5mm waste glass reclaimed sand, the raw materials of each component are taken ;

[0059] 2) Mix the transparent resin A component and the transparent resin B component uniformly first, then add the luminescent powder and waste glass regenerated sand in sequence, and stir evenly to obtain a bulk premix;

[0060] 3) Pour the bulk premix into steel molds or on the surface of dry permeable concrete, pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com