Compact jet flow air extractor for ship

A jet pumping, compact technology, applied in the direction of jet pumps, machines/engines, non-volume pumps, etc., can solve the problems of difficult to place ships, limited space of ships, large gas friction, etc., to ensure functional integrity and convenience Operation and maintenance, effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

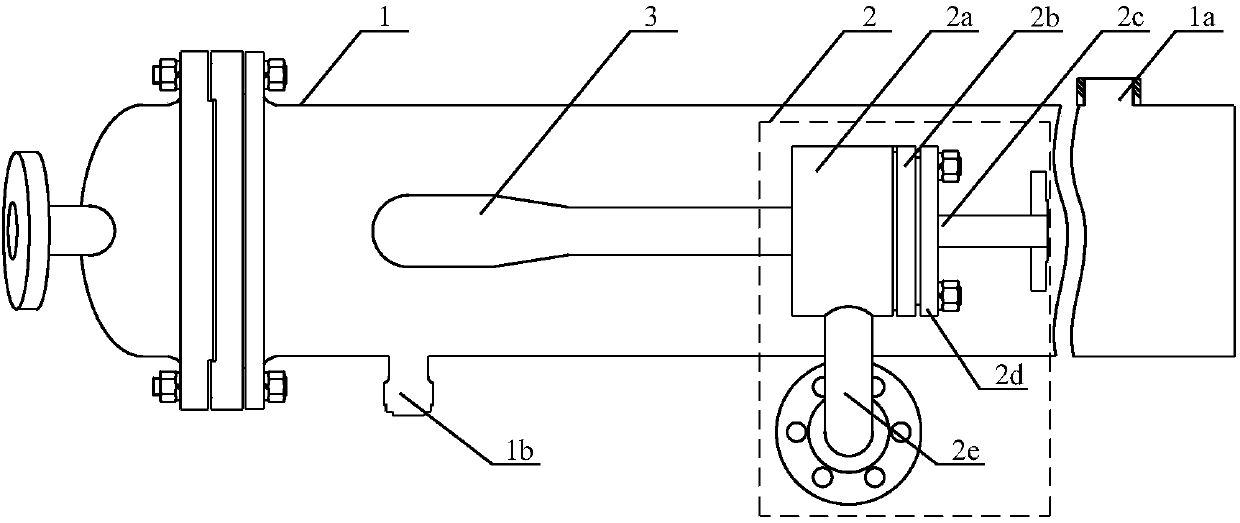

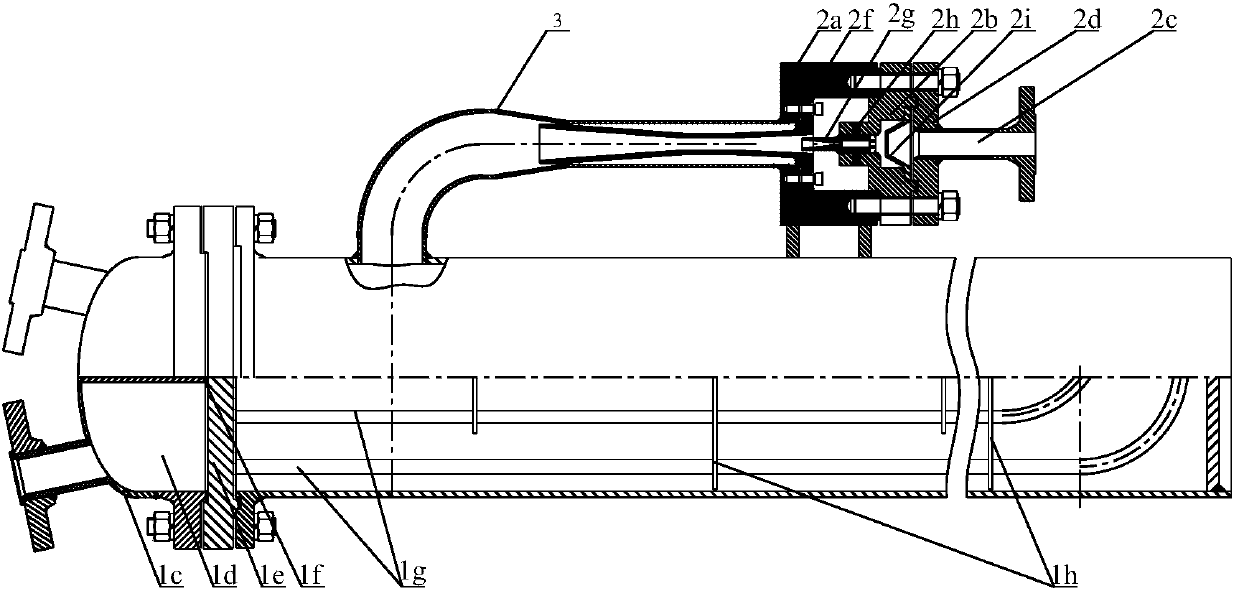

[0028] see figure 1 As shown, the compact jet air extractor for ships in the embodiment of the present invention includes a condenser 1, and a jet air extraction assembly 2 is arranged on the condenser 1, and the output end of the jet air extraction assembly 2 passes through an arc The connecting pipe 3 communicates with the input end of the condenser 1.

[0029] see figure 1 and figure 2 As shown, the jet air extraction assembly 2 includes a steam drainage tube base 2d, a nozzle base 2b, a receiving chamber 2a and a diffuser 2f that communicate with each other and are connected in sequence. The receiving chamber 2a is a hollow structure, and the steam drainage tube base 2d is provided with The arc-shaped steam draft pipe 2c is provided with a nozzle 2g on the nozzle seat 2b, and the distance between the nozzle 2g and the nozzle seat 2b ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com