A kind of in-situ infrared spectrum sample pressing device and its application

A technology of infrared spectroscopy and tablet pressing device, which is applied in the field of infrared spectroscopy analysis, can solve the problems of high sample density, difficult sample laying, and small volume, and achieve the effect of small volume, easy implementation, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Molecular sieve in situ infrared spectroscopy sample tableting

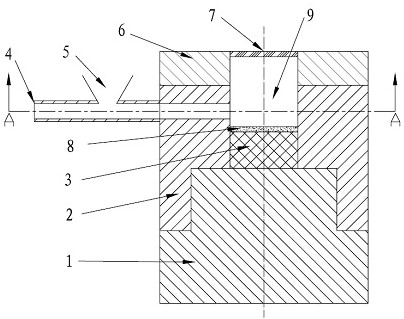

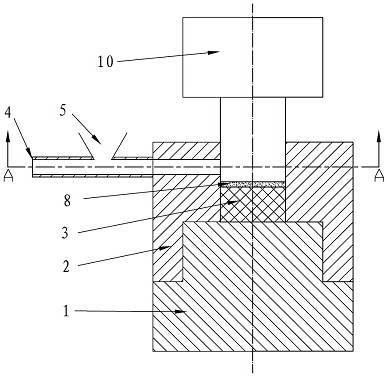

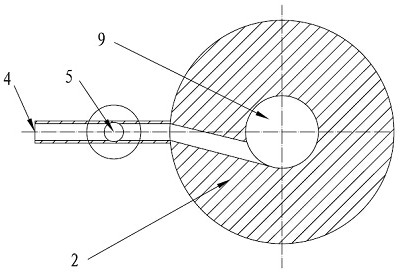

[0033] In the present embodiment, the molecular sieve sample is first added to the in situ infrared spectral tableting apparatus, in accordance with the instructions Figure 1Position and connection relationship to assemble the tablet pressing device, the air inlet 4 is connected to the high pressure nitrogen with a pressure of 1MPa, so that the high-pressure nitrogen flows in the intake port 4 and the sample chamber 9, and is discharged by the filter medium 7 on the cover plate 6, maintaining the state for 2 min so that the gas flow is in a stable state. Take 0.2g of the milled and particle diameter of less than 2 microns of molecular sieve sample powder, added to the sample addition port 5, the sample is carried into the sample chamber 9 by the high-pressure gas, and quickly rotated inside it, turned to maintain the state for 2min, so that the sample is evenly dispersed in the sample chamber 9. Then turn off ...

Embodiment 2

[0036] The injection and tableting methods are the same as In Example 1, but the molecular sieve sample is changed to a hydrogenation catalyst (ground to a particle diameter of less than 2 microns). Comparison Example 1:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com