A visual ct device for hydrate phase transition process based on high pressure throttling and temperature control technology

A high-pressure throttling and hydrate technology, which is applied in the field of basic hydrate research and can solve the problems of difficult measurement and realization of the decomposition surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

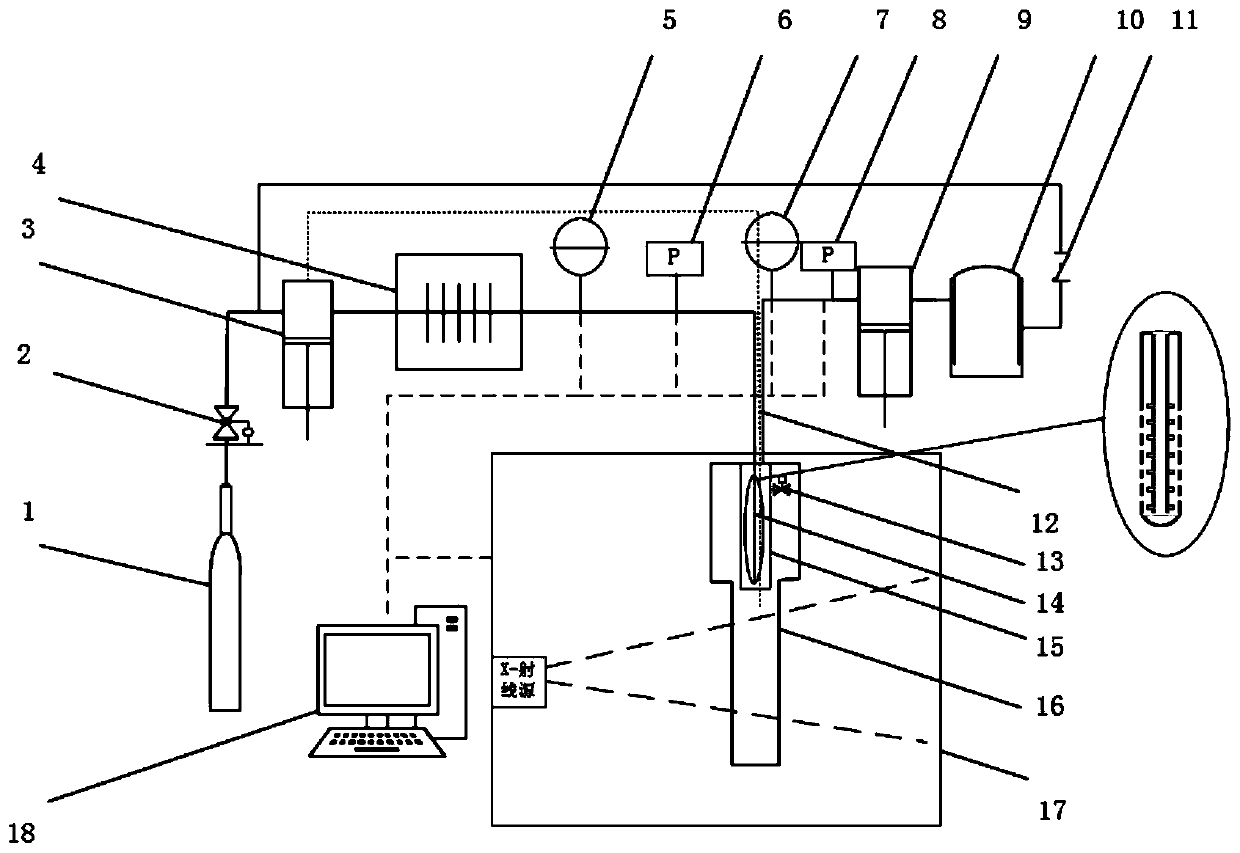

[0021] figure 1 Shown is a schematic diagram of the structure of the X-ray CT device for studying the fractal theory of the formation and decomposition process of natural gas hydrate.

[0022] (1) The preparation process is: take out the temperature control pool 15, open the self-operated pressure regulating valve 13, inject a certain amount of water into the reaction pool 16, then put the temperature control pool 15 into the reaction pool 16, and connect the experimental device . Turn on the X-ray CT scanning device to scan.

[0023] (2) The gas injection process is: open the pressure regulating valve 2, open the first air pump 3, make the first air pump 3 constant pressure (high pressure) gas injection, the initial gas injection process, the first temperature sensor 5, the second temperature sensor 7, The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com