Jet accumulation point gas-liquid separator

A technology of gas-liquid separator and gathering point, which is applied in the field of separation of solid-phase powder and liquid-phase mist, and achieves the effect of simple and compact structure, high separation efficiency and broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

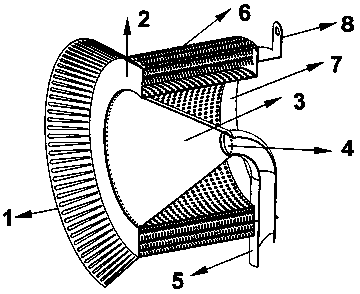

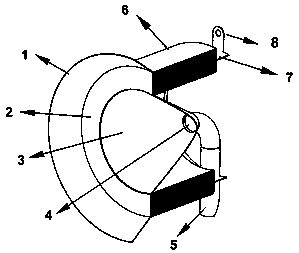

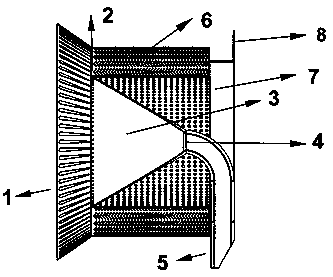

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0018] A jet gathering point gas-liquid separator, such as Figure 1-6 As shown, it includes a cylindrical filter 6 with holes at both ends. Filling), with one end face 2 of the cylindrical filter (the surface formed by the outer edge line and the inner edge line of the end face 2 can be in the same plane, or the inner edge line can be shrunk toward the inside of the filter, and the similar cone shape that is not on the same plane Structure) The outer edge line expands outwards and expands into a conical absorption mouth surrounding layer 1, and there are pores on the surrounding layer 1, and the end surface shrinks into the filter along the edge of the inner hole of the filter to form a funnel structure layer 3 , there is a through hole at the central point of the structure, that is, the liquid di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com