High-strength, high-brittleness, high-density similar material for deep hard rock and its preparation method

A similar material, high-strength technology, applied in the field of deep hard rock high-strength, high-brittleness, high-severity similar materials and their preparation, can solve the problems of low strength and poor brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] This embodiment also provides a preparation method based on the above materials.

[0036] A method for preparing similar materials with high strength, high brittleness and high gravity in deep hard rock, including:

[0037] Weigh calcite sand, calcite powder, dolomite sand, gypsum, cement and PbO powder, mix and stir evenly to obtain a mixed solid;

[0038] Weigh water and water reducer and mix well to obtain a mixed solution;

[0039] Pour the mixed solution into the mixed solid material, stir evenly and put it into a mold;

[0040] After the initial setting of the material in the mold, compact molding with a press;

[0041] The material is demolded after curing in a dry and ventilated place indoors;

[0042] Curing under natural conditions indoors, and then curing at high temperature until the material hardens and the quality is constant.

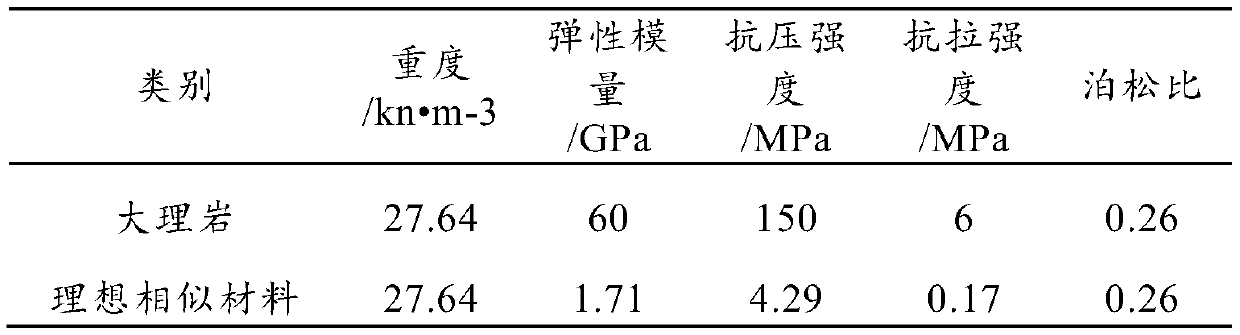

[0043] Present embodiment also provides a kind of concrete material composition and prescription:

[0044] Aggregate is calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com