Damping polycarboxylic acid water reducing agent as well as preparation method and special production equipment thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of concrete admixtures, can solve the problems of inability to obtain molecular weight polycarboxylic acid products, weak polyether polymerization activity, poor mud blocking effect, etc., and achieves good mud blocking effect and molecular weight. The effect of narrow distribution and high double bond retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

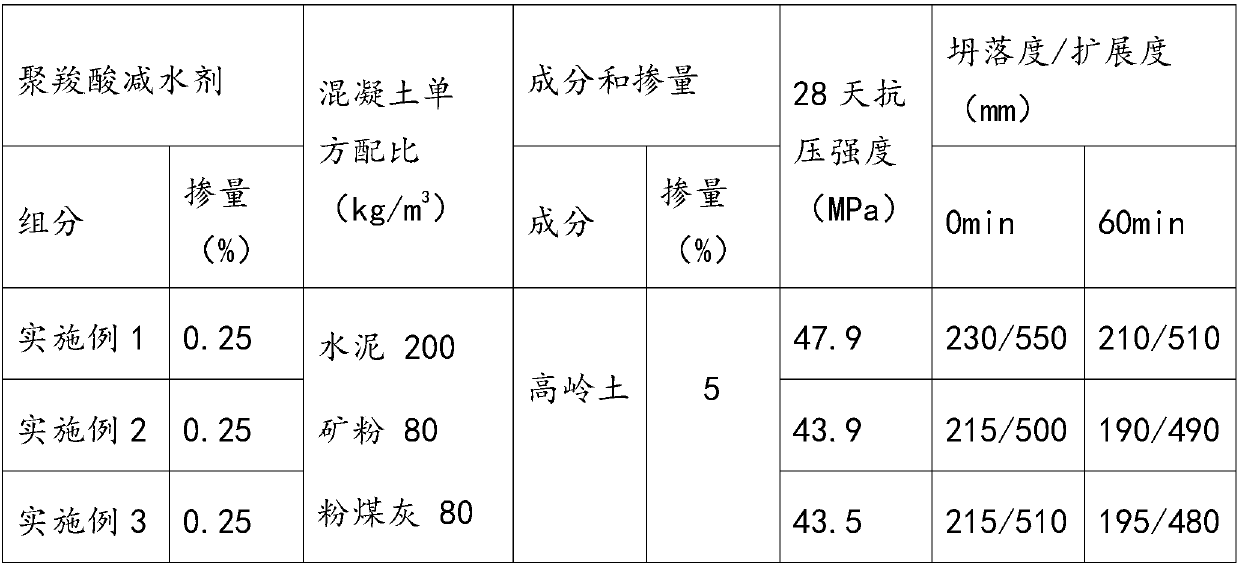

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of the above-mentioned mud-resistance polycarboxylate superplasticizer, comprising the following steps.

[0038] Step 1, synthesizing 4-hydroxybutyl vinyl polyoxyethylene polyoxybutylene ether;

[0039] 4-hydroxybutyl vinyl ether with a total weight of 5-15% is pre-reacted under the action of a catalyst, and the product is put into the remaining 4-hydroxybutyl vinyl ether, and a mixture of ethylene oxide and butylene oxide is added Reaction to obtain 4-hydroxybutyl vinyl polyoxyethylene polyoxybutylene ether oligomer with a molecular weight of 300-450;

[0040] Then, 5-15% of the total amount of 4-hydroxybutyl vinyl polyoxyethylene polyoxybutylene ether oligomer is pre-reacted under the action of a catalyst, and the product is put into the remaining 4-hydroxybutyl vinyl polyoxyethylene A mixture of ethylene oxide and butylene oxide is added to the polyoxybutylene ether oligomer for reaction to obtain 4-hydroxybut...

Embodiment 1

[0063] Step 1, synthesizing 4-hydroxybutyl vinyl polyoxyethylene polyoxybutylene ether.

[0064] Firstly carry out one-stage synthesis, this step synthesizes and synthesizes 4-hydroxybutyl vinyl polyoxyethylene polyoxybutylene ether oligomer, and the specific process is:

[0065]Open the discharge valve of the 4-hydroxybutyl vinyl ether storage tank, add 50Kg of 4-hydroxybutyl vinyl ether in the first-stage pre-reactor, open the stirring device to stir, and use a catalyst continuous feeder to feed a Add 0.5Kg of sodium catalyst metal into the first-stage pre-reactor, pass steam and cooling water into the jacket, keep the temperature at 25°C, and stir for 0.5h to obtain the first-stage pre-reactant.

[0066] Then, open the discharge valve of the primary reactor, put the primary pre-reactant generated into the primary reactor, and at the same time, open the discharge valve of the 4-hydroxybutyl vinyl ether storage tank, and put it into the primary reactor 950Kg of 4-hydroxybuty...

Embodiment 2

[0078] Step 1, synthesizing 4-hydroxybutyl vinyl polyoxyethylene polyoxybutylene ether.

[0079] Firstly carry out one-stage synthesis, this step synthesizes and synthesizes 4-hydroxybutyl vinyl polyoxyethylene polyoxybutylene ether oligomer, and the specific process is:

[0080] Open the discharge valve of the 4-hydroxybutyl vinyl ether storage tank, add 85Kg of 4-hydroxybutyl vinyl ether to the first-stage pre-reactor, open the stirring device to stir, and use a catalyst continuous feeder to feed a Add 1.0Kg of sodium catalyst metal into the first-stage pre-reactor, pass steam and cooling water into the jacket, keep the temperature at 30°C, and stir for 1.0h to obtain the first-stage pre-reactant.

[0081] Then, open the discharge valve of the primary reactor, put the primary pre-reactant generated into the primary reactor, and at the same time, open the discharge valve of the 4-hydroxybutyl vinyl ether storage tank, and put it into the primary reactor 915Kg of 4-hydroxybut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com