Broach lifting and stretching type intelligent carrier

An intelligent handling and telescopic technology, which is applied to the buildings where cars are parked, building types, buildings, etc., can solve the problems of low utilization rate of the garage, large movement in the height direction, and the space of the car storage floor is not compact. The effect of reducing construction cost, stable operation and high safety factor of equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below through non-limiting embodiments and in conjunction with the accompanying drawings.

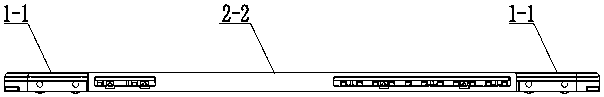

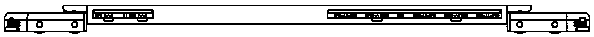

[0069] see Figure 1 to Figure 3 , Comb-tooth lifting telescopic intelligent carrier, composed of a telescopic module 2-2 and 2 identical walking lifting modules 1-1.

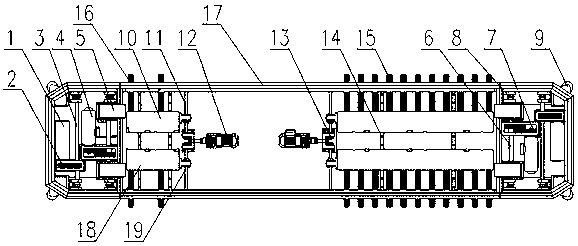

[0070] see image 3 , Figure 9 to Figure 10 , the walking lifting module 1-1 is composed of a vehicle body 22, a lifting device and a walking mechanism,

[0071] The traveling mechanism includes: a traveling motor reducer 1 fixed on one end of the vehicle body, a traveling reduction box 2 fixed on the vehicle body 22, a traveling drive shaft 3, 2 first traveling wheels 24, 2 second traveling wheels 25, 2 Drive sprocket 20, 2 driven sprockets 8; the input shaft of the travel reduction box 2 is connected with the output shaft of the travel motor reducer 1, and the output shaft is a biaxial extension; the travel drive shaft 3 and the output shaft of the travel reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com