Electromagnetic shielding waveguide ventilation window

A technology of electromagnetic shielding and ventilation windows, which is applied in the directions of magnetic/electric field shielding, ventilation layout, electrical components, etc., can solve the problems of low strength and poor high temperature resistance, and achieve strong high temperature resistance, good damage resistance, and good overall The effect of sex and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

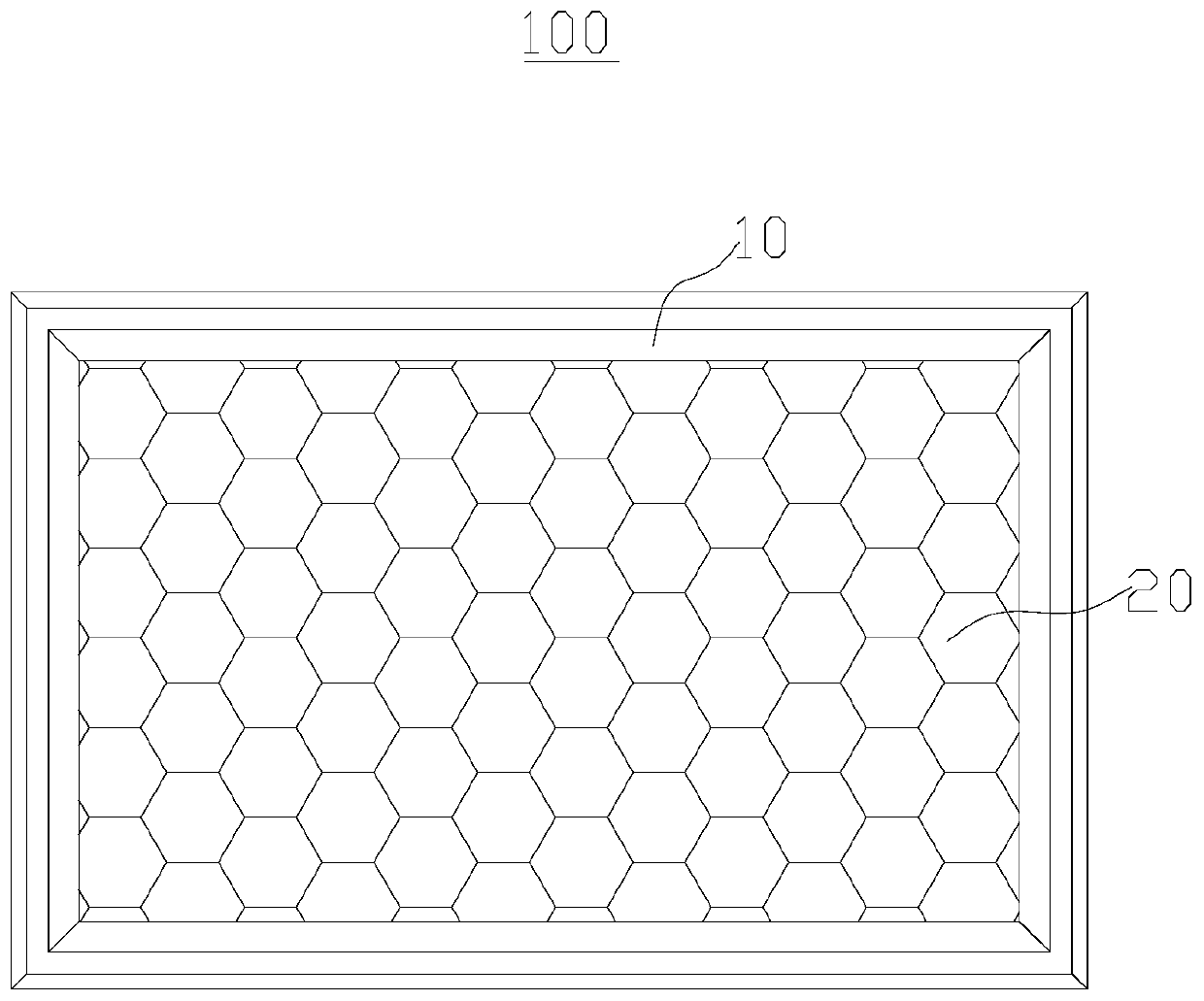

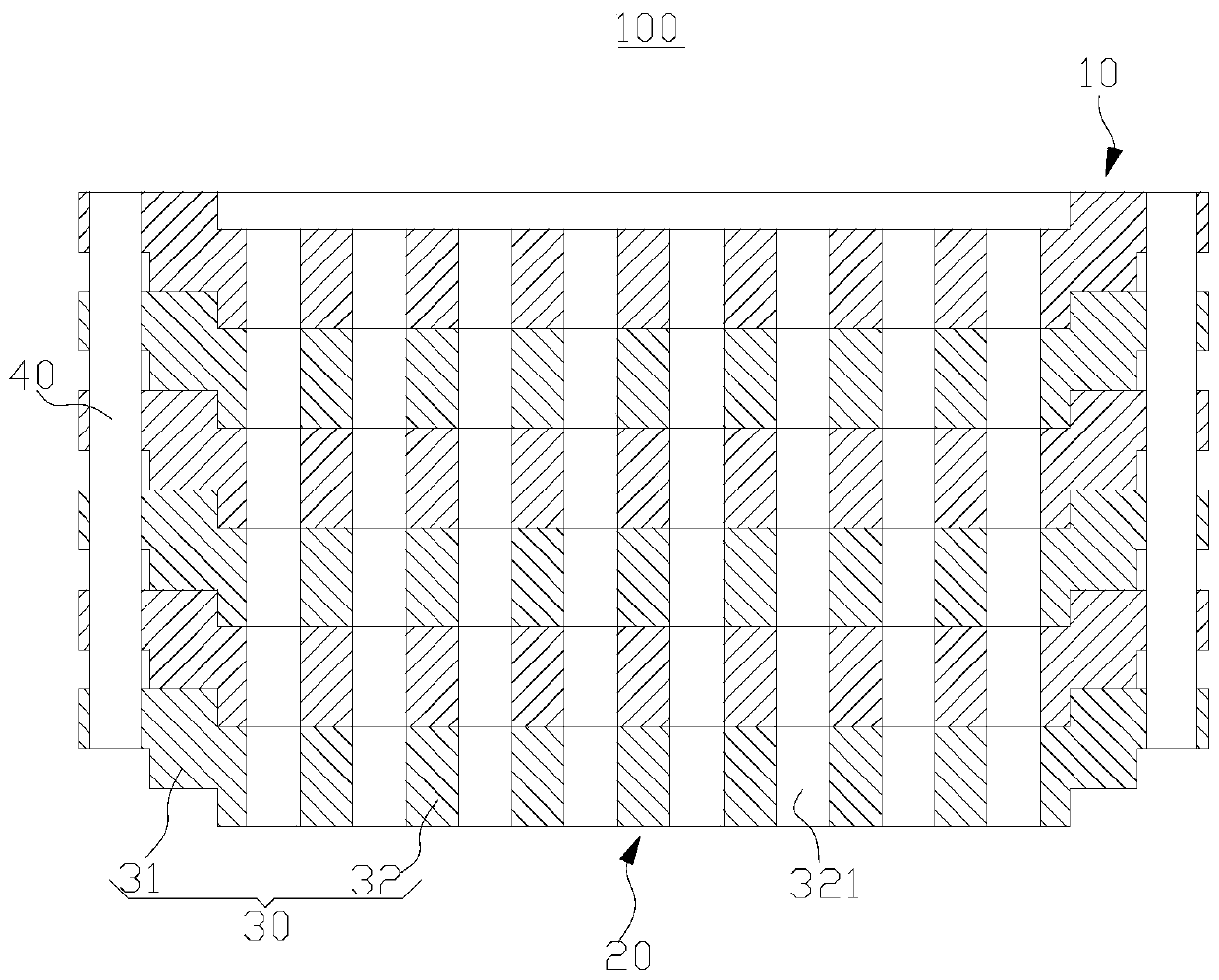

[0040] Such as image 3 As shown, the present embodiment provides an electromagnetic shielding waveguide ventilation window 100, including a limiting member 40 and a plurality of layers 30, all the layers 30 are sequentially arranged and connected from the bottom to the top, and the layers 30 and the layers 30 pass through the limiter. The position piece 40 is positioned.

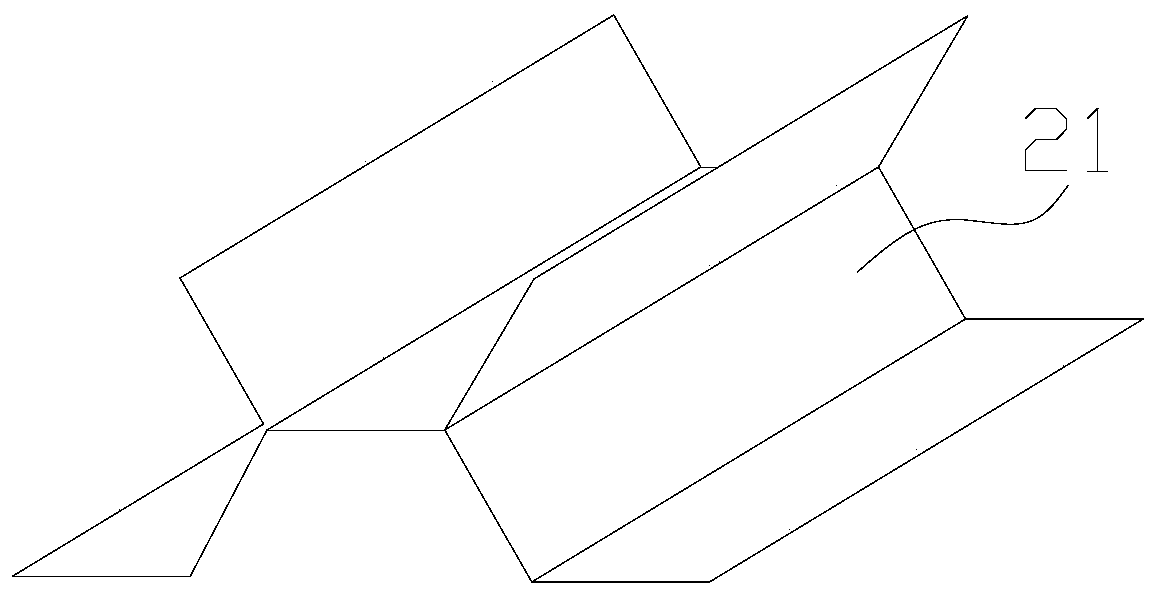

[0041] The layer 30 is made of metal, such as aluminum alloy, copper alloy, titanium alloy, stainless steel, high temperature alloy, high temperature tungsten, high temperature niobium, high temperature molybdenum and other metals. In this example, if Figure 4 As shown, the ply 30 is a circular structure. The ply 30 includes a bearing part 31 and a honeycomb part 32 located at the center of the bearing. The bearing part 31 and the honeycomb part 32 are of an integrated structure. It is a honeycomb structure, and the honeycomb portion 32 is provided with a plurality of honeycomb holes 321 , and the honeyc...

Embodiment 2

[0054] This implementation provides a processing method for the electromagnetic shielding waveguide ventilation window 100 in the above-mentioned embodiment, and the specific steps are as follows:

[0055] Machining of the ply 30: Firstly, the shape of each ply 30 is processed, so that the concave portion 34 and the protruding portion 33 are formed on the ply 30 . Next, hole machining is performed on each layer 30 so that a plurality of honeycomb holes 321 are formed at the center of the layer 30 and a limiting hole 314 is formed on the top of the layer 30 . The area of the layer sheet 30 where the honeycomb holes 321 are located is the honeycomb portion 32 , and the area of the layer sheet 30 other than the honeycomb portion 32 is the bearing portion 31 . The methods of shape processing and hole processing include but are not limited to mechanical processing, precision stamping, electrolytic etching, and chemical etching; after hole processing is performed on the layer 30...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap