Electric pressure cooker steam extraction device

A technology of electric pressure cooker and discharge device, which is applied to the structure of utensils with integral electric heating devices, garbage cans, cooking utensils, etc., and can solve the problem of large solenoid valve 230 itself, large space for solenoid valve 230, and large solenoid valve power, etc. problems, to achieve the effect of simplifying the structure, reducing production costs and reducing accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

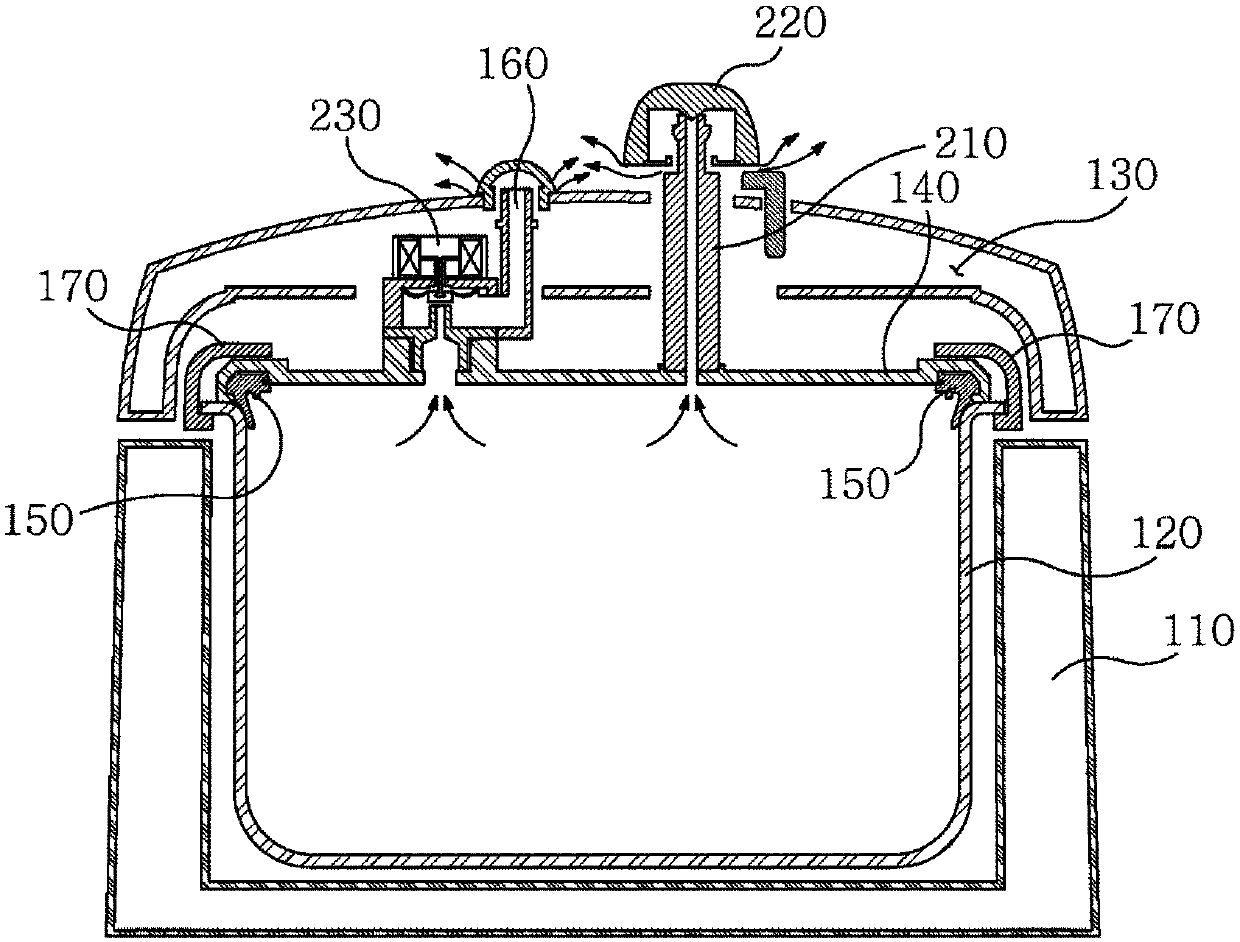

[0027] Such as figure 2 As shown, the steam circulation pipe 210 passes through the inner pot cover 140 and the outer cover 130 of the electric pressure cooker, thereby communicating the inside of the pressure cooker with the outside air, and serves as the steam passage pipe 210 .

[0028] The pressure relief valve 220 is arranged on the upper half of the steam circulation pipe 210, and moves up and down within a certain distance in the upper half of the steam circulation pipe 210. With the operation of the pressure relief valve 220, the steam outlet 180 is opened, Internal steam escapes from this, thereby regulating the internal pressure of the pressure cooker.

[0029] The solenoid valve 230 is arranged inside the outer cover 130, and the solenoid valve is provided with a plunger 240. The plunger 240 and the solenoid valve 230 operate in linkage. The end of the plunger 240 is provided with a "<" or a "<" wedge-shaped inclined end.

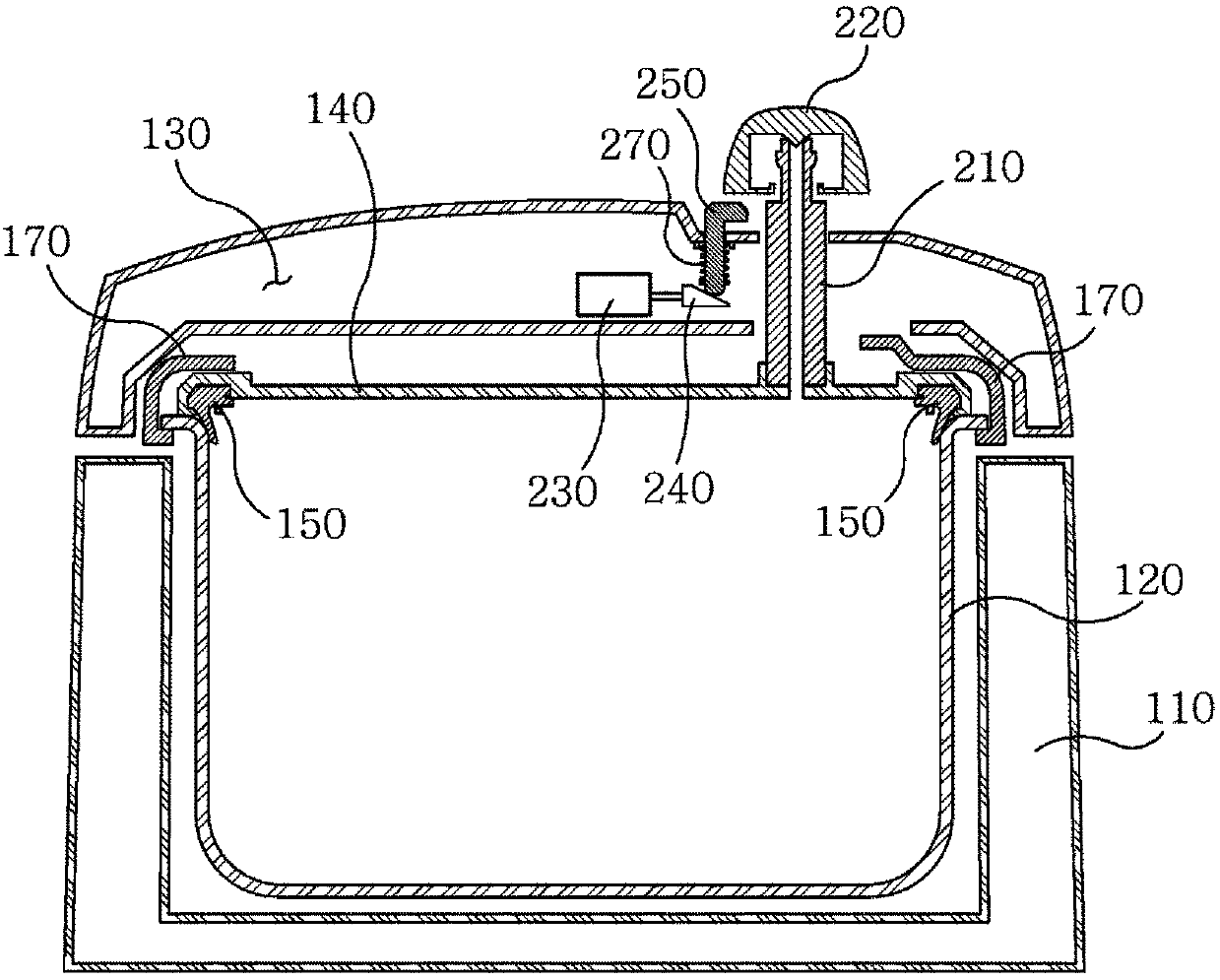

[0030] The lifting pin 250 and the elec...

Embodiment 2

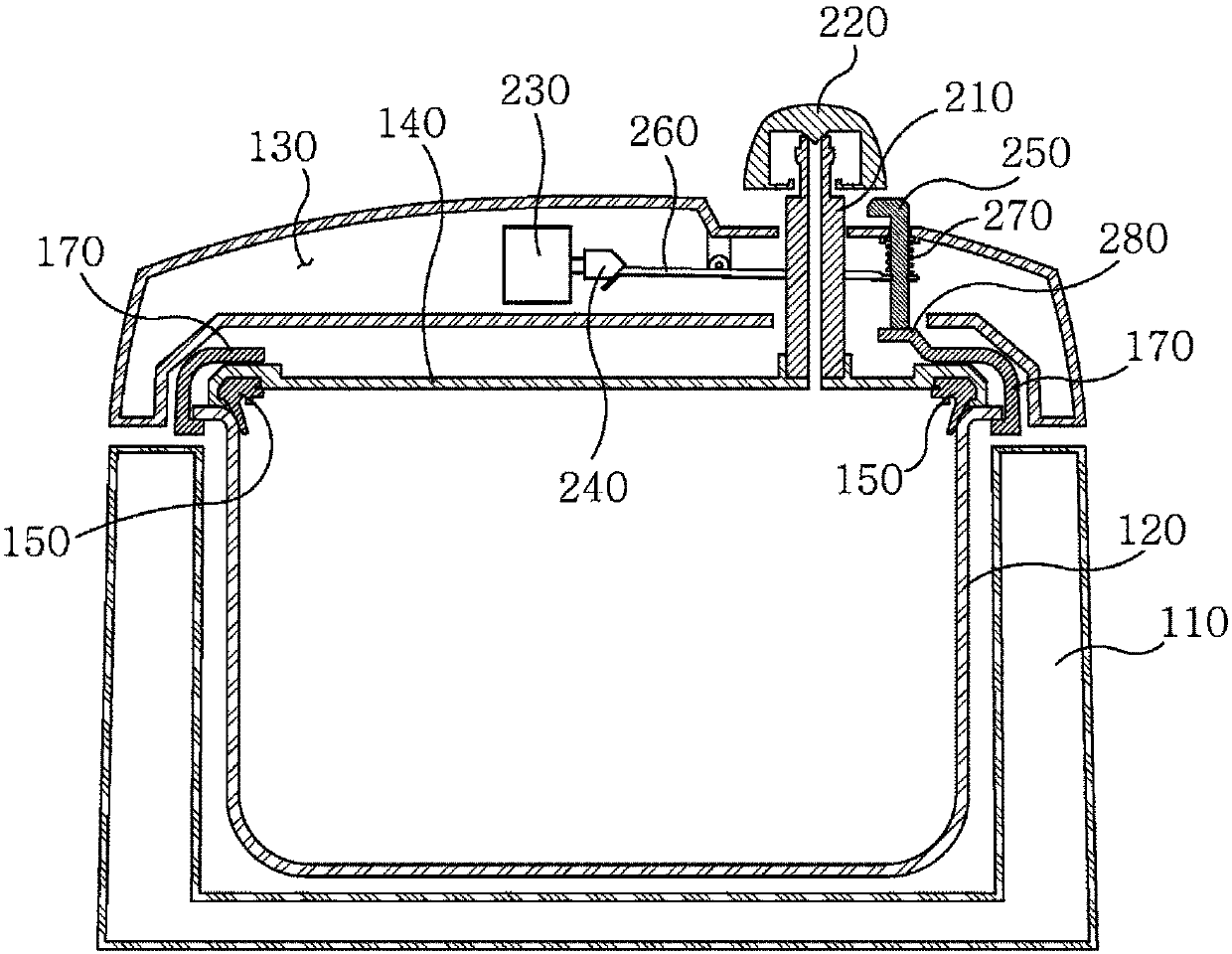

[0034] Such as image 3 The figure shows another implementation example of the present invention, which adopts a structure in which the action transmission rod 260 is embedded between the plunger 240 and the lifting pin 250, wherein the steam circulation pipe 210, the pressure relief valve 220, the solenoid valve 230, the plunger 240, etc. Structure and function are identical with embodiment 1. The plunger 240 is not connected to the lift pin 250 , and when the plunger 240 rotates the transmission rod 260 , the lift pin 250 is linked to lift.

[0035] The action transmission rod 260 is connected by a pin and is arranged inside the outer cover 130 . The partial end of the action transmission rod 260 is connected with the inclined end of the plunger 240 , and the action transmission rod 260 rotates up and down with the operation of the plunger 240 . That is, when the plunger 240 advances (moves to the right), the motion transmitting lever 260 rotates counterclockwise, and when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com