Screw hole positioning and screw locking-and-dismounting device based on visual servo

A technology of screw hole positioning and visual servoing, which is applied in workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of difficulty in ensuring positioning accuracy, low positioning accuracy, and few positioning times, and achieves increased work. range, improved positioning accuracy, improved accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

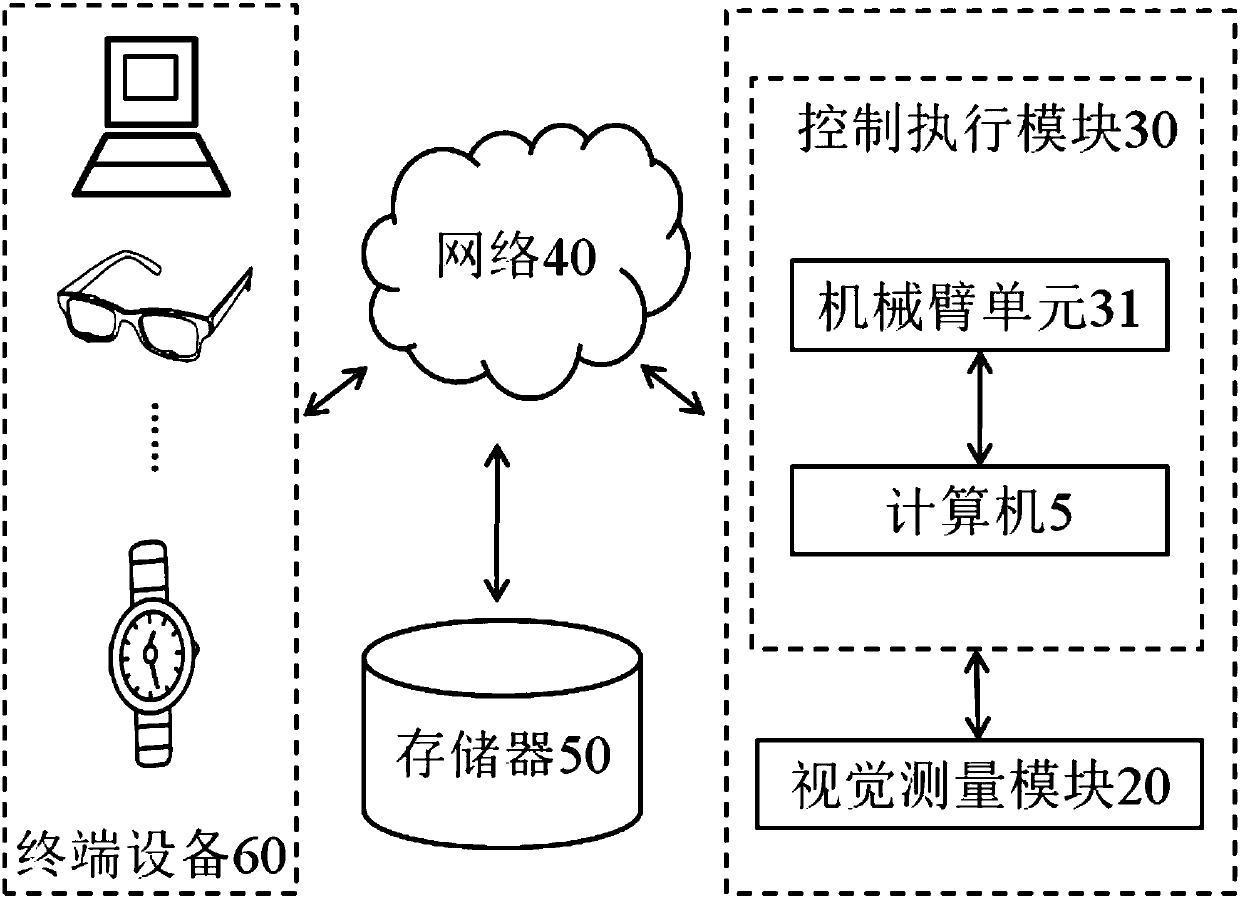

[0024] The present invention provides a screw hole positioning and locking and unloading screw device based on visual servoing, which is used for positioning screw holes and locking and unloading screws, such as figure 1 As shown, the screw hole positioning and screw locking and unloading device based on visual servoing includes a visual measurement module 20 and a control execution module 30. The control execution module 30 includes a robotic arm unit 31 and a computer 5. The visual measurement module 20 and The control execution modules 30 perform data transmission and communication through the network 40 .

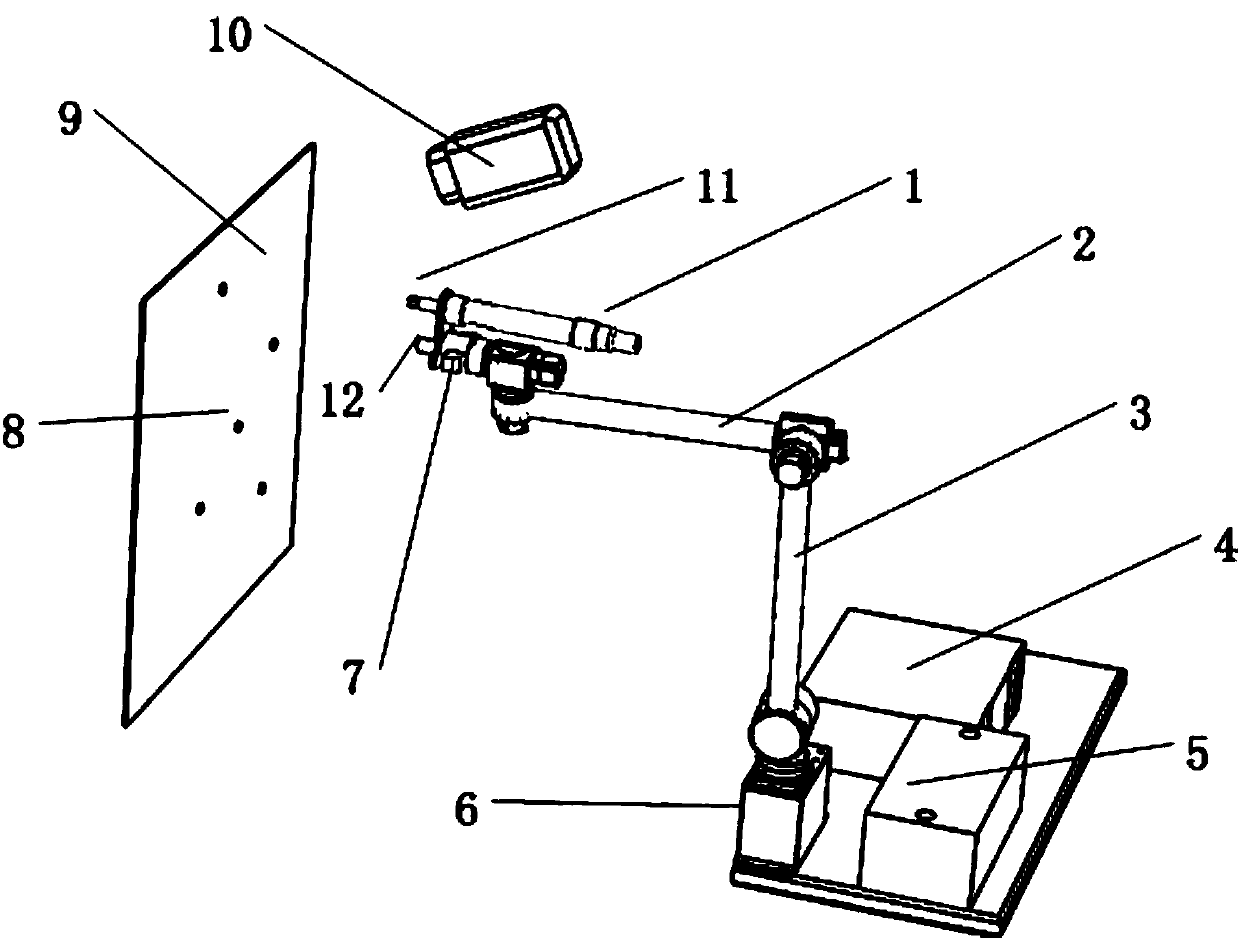

[0025] Such as figure 2 The shown schematic diagram of the screw hole positioning and locking and unloading screw device based on visual servoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com