Wood processing sawdust processing equipment for forestry engineering

A technology for processing equipment and sawdust, applied in wood processing equipment, manufacturing tools, multi-purpose machinery, etc., can solve problems such as pipeline blockage, difficult cleaning, and equipment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

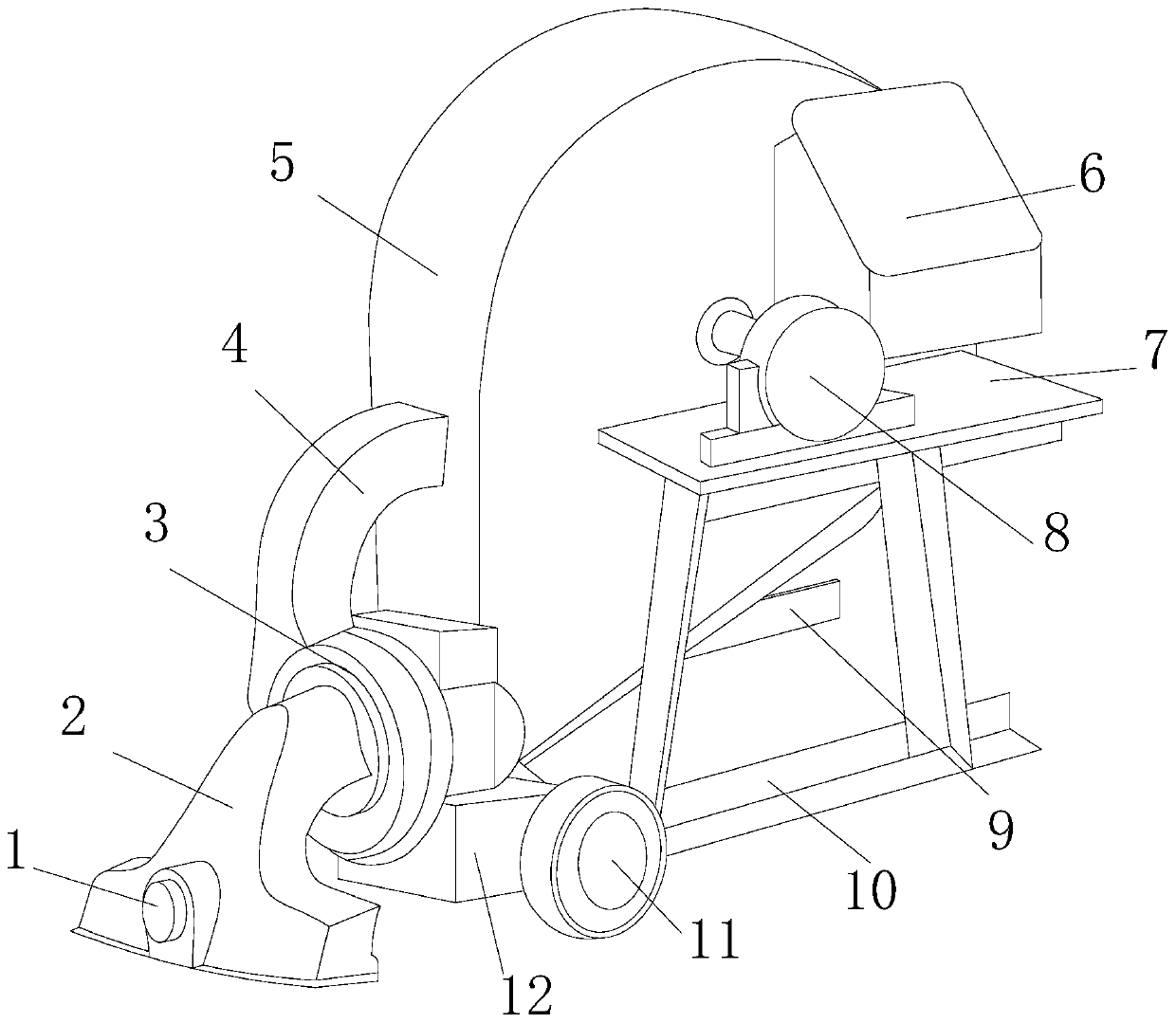

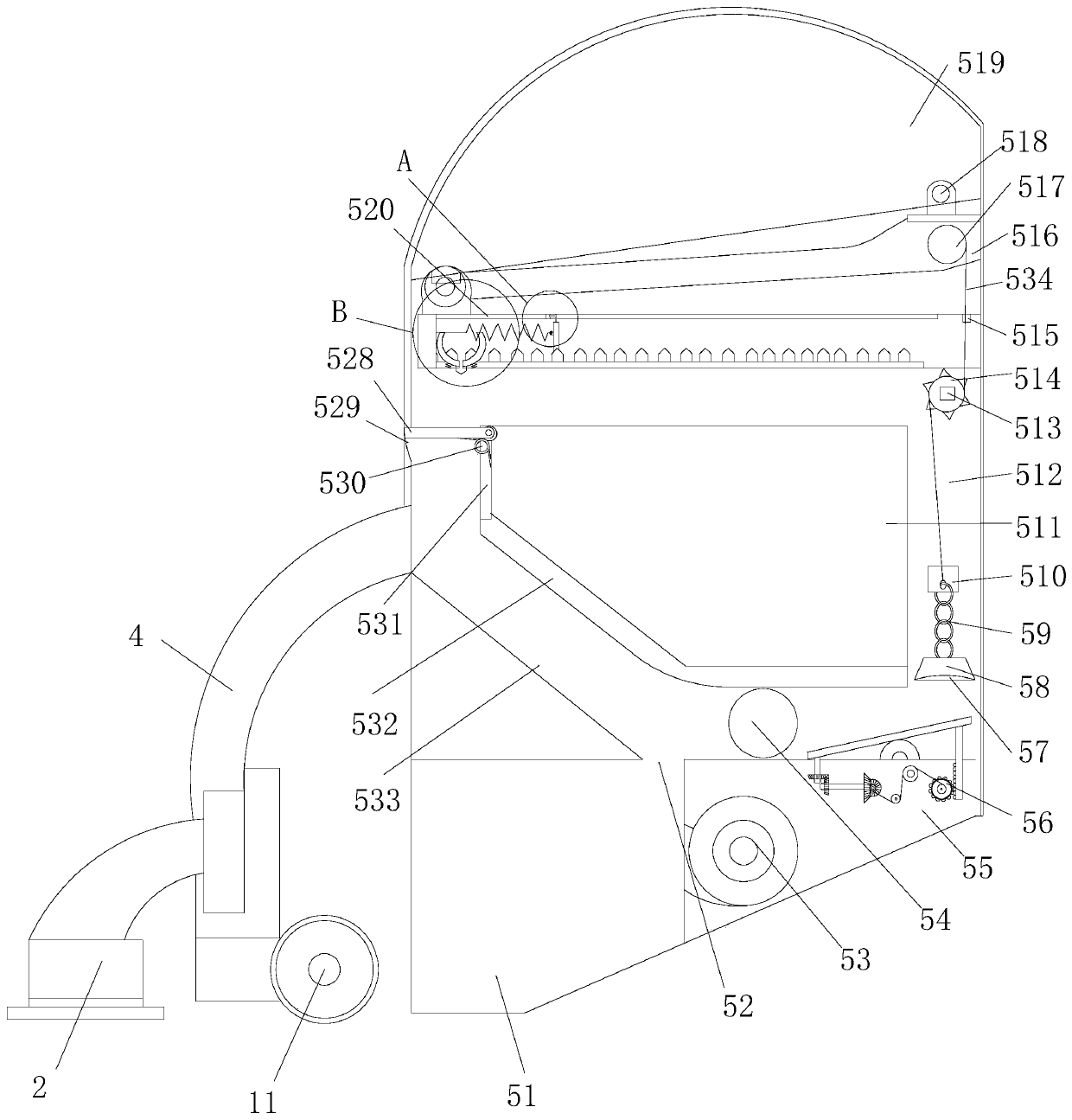

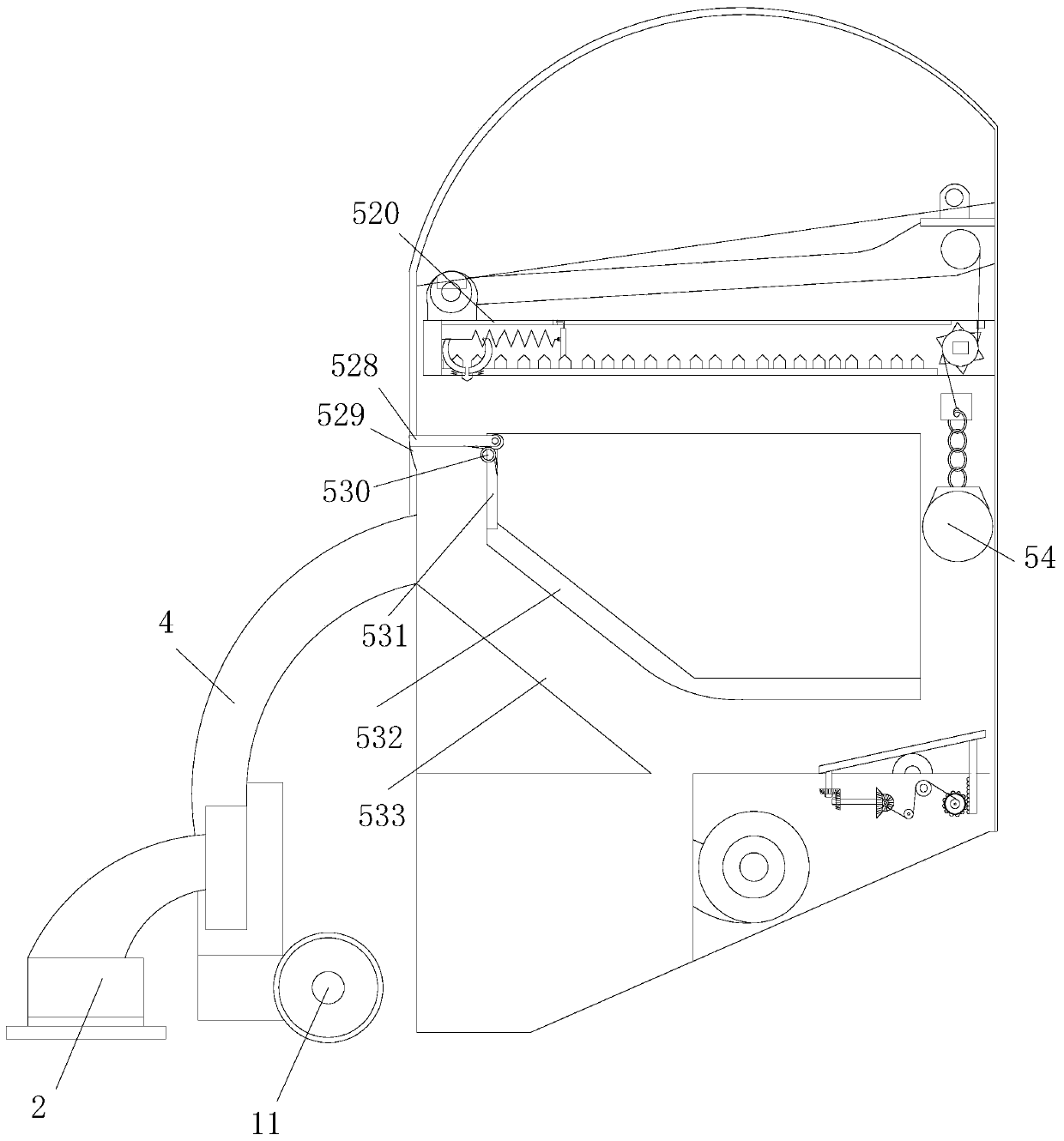

[0025] see Figure 1-Figure 7 , the present invention provides an environment-friendly wood processing sawdust processing equipment for forestry engineering, its structure includes fastening screw 1, sawdust inlet 2, fixed plate 3, through pipe 4, anti-clogging device 5, observation window 6, placing table 7, Motor 8, cooling window 9, bracket 10, roller 11, support box 12, described sawdust inlet 2 is mechanically connected with fixed plate 3, described sawdust inlet 2 is provided with fastening screw 1, described fixed plate 3 One end is fixed on the support box 12, and the other end of the fixed plate 3 communicates with the anti-clogging device 5 through the through pipe 4. One side of the anti-clogging device 5 is horizontally welded with a placement platform 7, and the placement platform 7 The bottom end is vertically welded with a bracket 10 and a motor 8 is placed on its top surface, the motor 8 is mechanically connected with the anti-blocking device 5, and the anti-bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com