Cement particle material sample preparation device and method for preparing cement particle material sample

A technology of cementing particles and granular materials, which is applied in the preparation of test samples, manufacturing tools, ceramic molding machines, etc., can solve the problem that cemented granular material samples cannot truly and accurately reflect physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

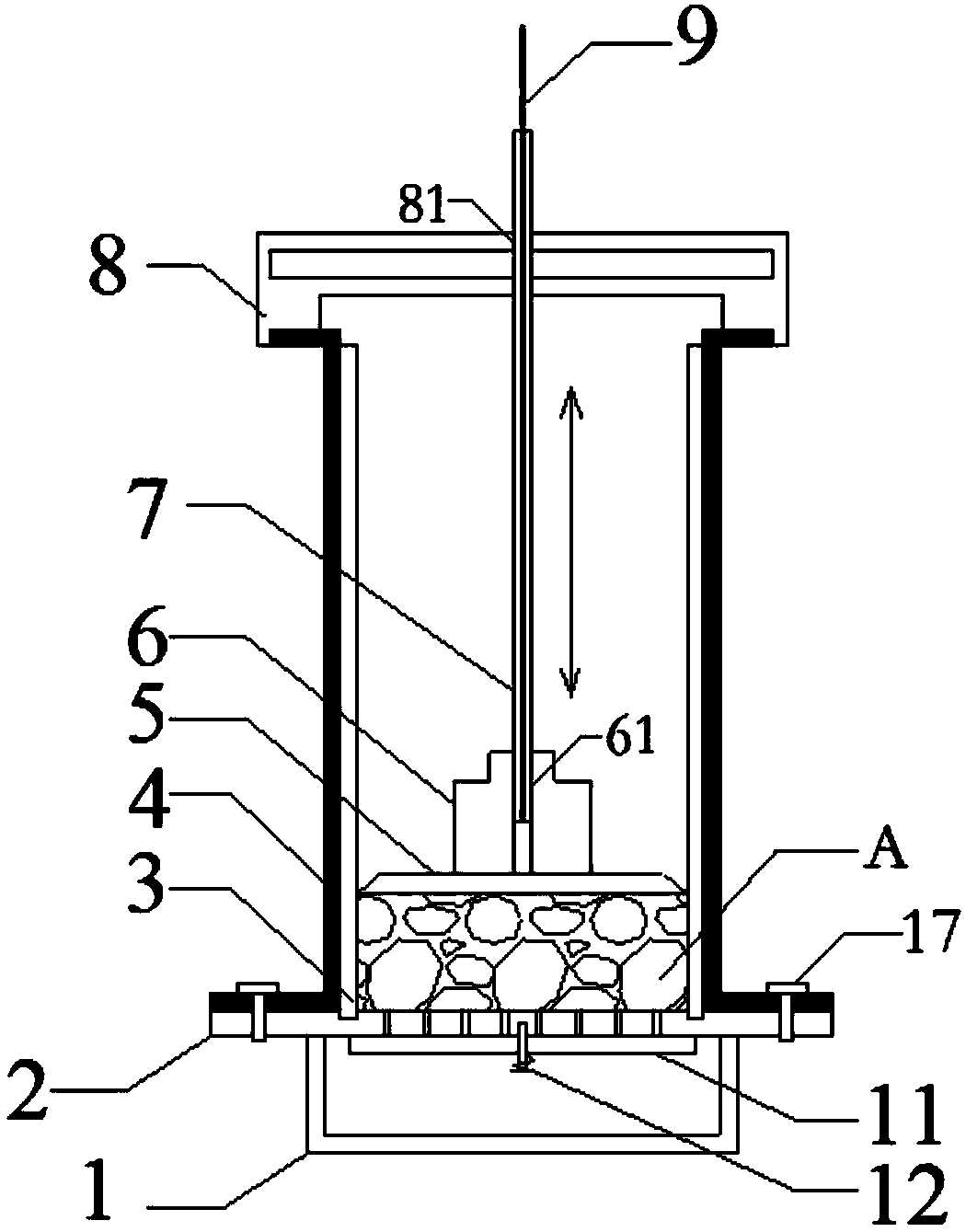

[0073] According to an embodiment of the present invention, the preparation method uses the above-mentioned sample preparation device for cemented granular materials, and, referring to Figure 5 , the preparation method comprises:

[0074] S100: Combine the base, the slurry plate and the sample preparation cylinder, and put the limit sleeve on the outside of the sample preparation cylinder.

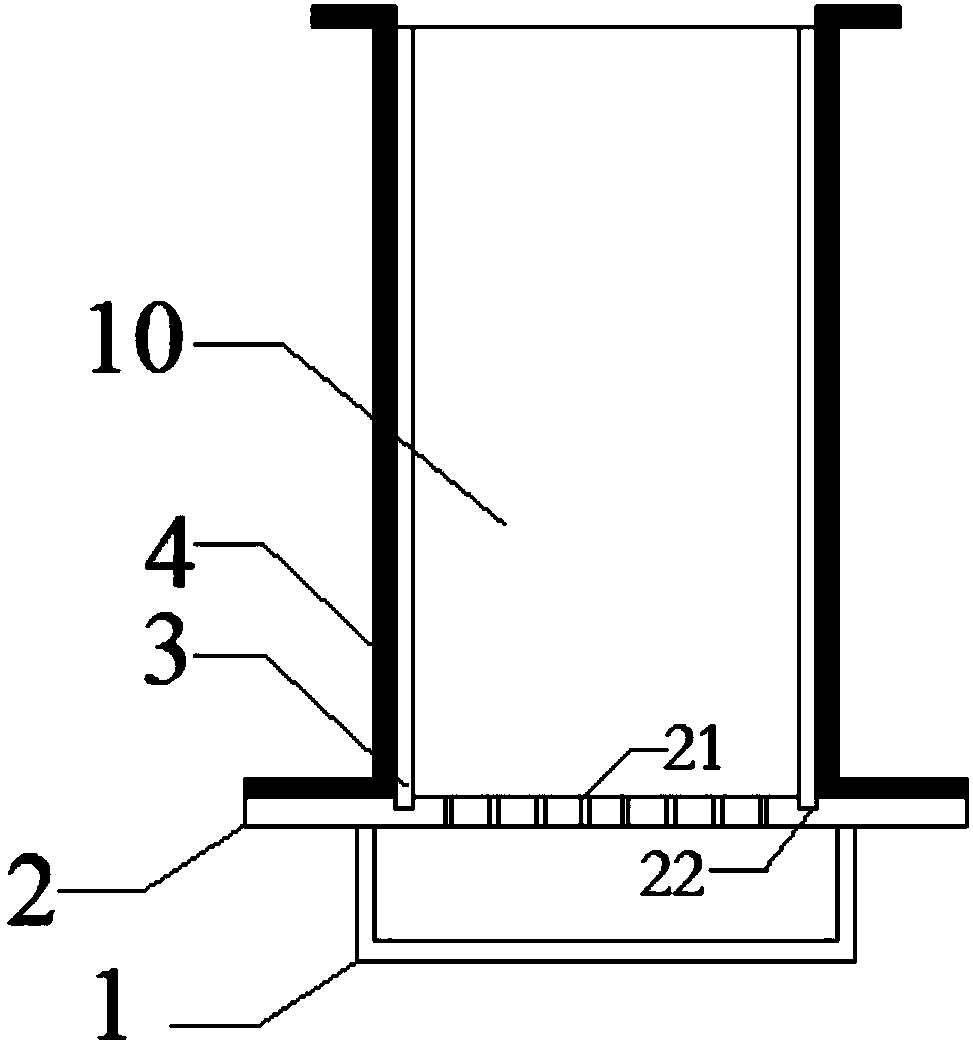

[0075] In this step, the base 1 , the slurry plate 2 and the sample preparation cylinder 3 are combined, and the limit sleeve 4 is placed on the outside of the sample preparation cylinder 3 to seal the sample preparation cylinder 3 .

[0076] According to the embodiment of the present invention, the specific method of combining the base 1, the slurry plate 2, the sample preparation cylinder 3 and the limit sleeve 4 is not particularly limited, and those skilled in the art can carry out according to the specific shape of the sample preparation cylinder 3 Adjustment. In some embodiments o...

Embodiment 1

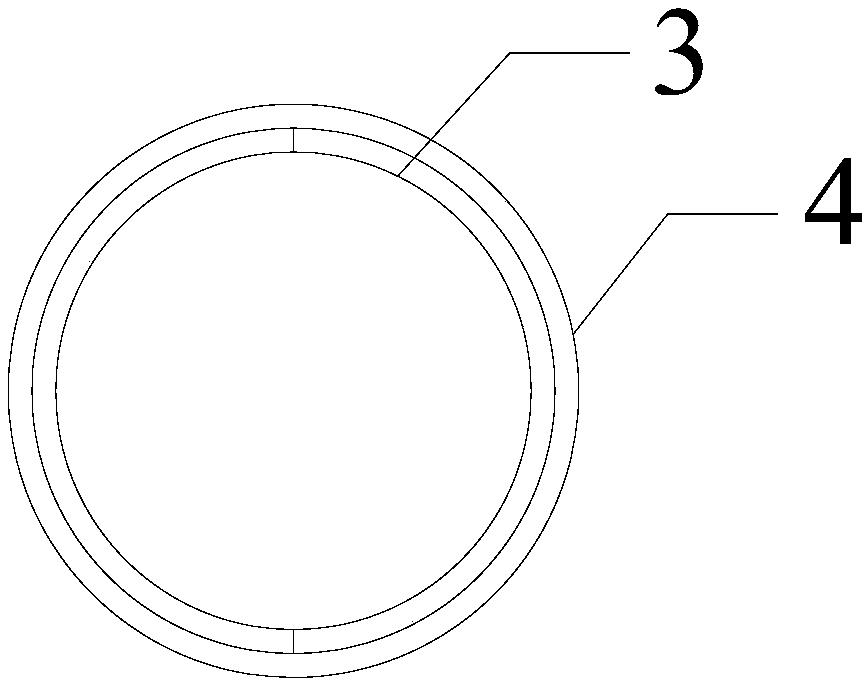

[0092] In this example, refer to Figure 1~4 The cemented granular material sample preparation device.

[0093] Among them, the sample preparation mechanism includes a sample preparation cylinder 3. The sample preparation cylinder 3 is composed of two split semicircular tubes. And use the limit cylinder 4 to seamlessly seal the sample preparation cylinder 3; the bottom end of the limit cylinder 4 is fixed on the permeable plate 2; the sealing plate 11 can be fixed on the permeable plate 2 by springs and bolts 12; the upper surface of the pouring plate 13 is engraved with The second groove 15 has the same inner and outer diameters as the inner and outer diameters of the pouring cylinder 14; the pouring cylinder 14 is embedded in the second groove 15 on the upper surface of the pouring plate 13; 2 have the same outer diameter; the pouring plate 13 is fixed on the upper end of the limiting cylinder 4; the raised end of the lower surface of the pouring plate 13 seals the upper su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com