Material conveying and distributing method for food machine

A distribution method and technology for food machines, which are applied in the directions of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problem of inability to parallelize multiple mechanisms, and achieve packaging production speed, easy counting and statistics, and improving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

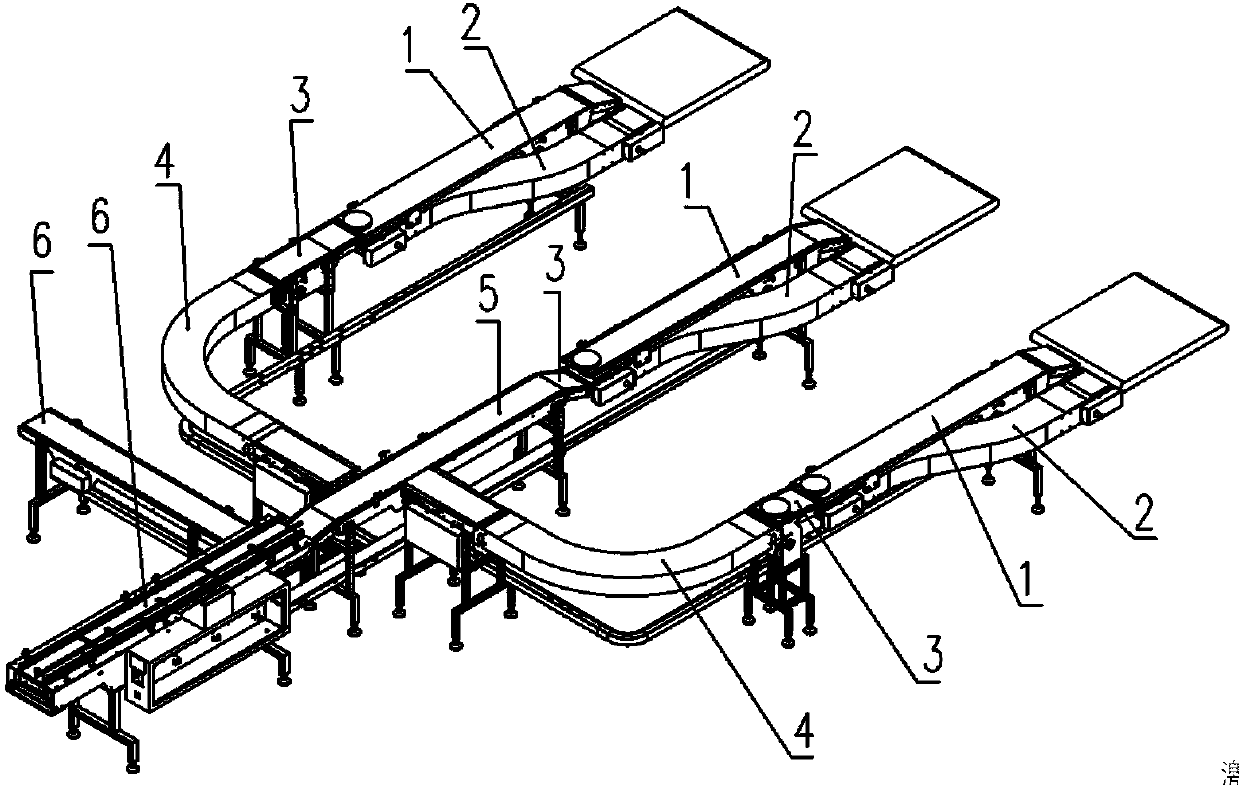

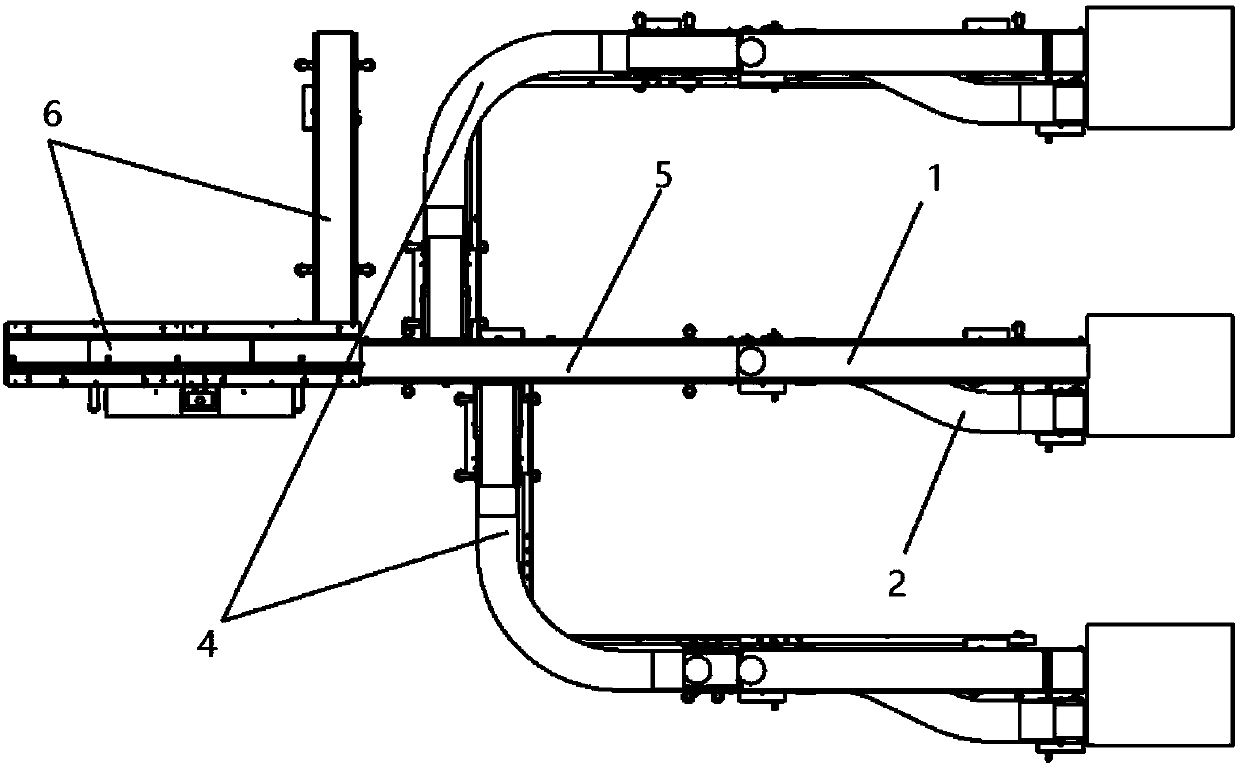

[0038] A material conveying and distributing method for a food machine, characterized in that it includes a material input step, a material integration and distribution step, and a material output step;

[0039] In the material input step, the material input line of the material input section receives the material from the previous station and transports the material to the main conveying line and each material receiving branch of the material distribution section, and the main conveying line input end and each material receiving branch The lane-changing mechanism of the road conveying selects the material input line with incoming materials to conduct and receive the materials;

[0040] In the material integration and distribution step, each material receiving branch of the material distribution section merges the materials received from the material input line into the main conveying line through their respective interfaces with the main conveying line, and the materials do no...

Embodiment 2

[0044] A material conveying and distributing method for a food machine, characterized in that it includes a material input step, a material integration and distribution step, and a material output step;

[0045] In the material input step, the material input line of the material input section receives the material from the previous station and transports the material to the main conveying line and each material receiving branch of the material distribution section, and the main conveying line input end and each material receiving branch The lane-changing mechanism of the road conveying selects the material input line with incoming materials to conduct and receive the materials;

[0046] In the material integration and distribution step, each material receiving branch of the material distribution section merges the materials received from the material input line into the main conveying line through their respective interfaces with the main conveying line, and the materials do no...

Embodiment 3

[0051] A material conveying and distributing method for a food machine, characterized in that it includes a material input step, a material integration and distribution step, and a material output step;

[0052] In the material input step, the material input line of the material input section receives the material from the previous station and transports the material to the main conveying line and each material receiving branch of the material distribution section, and the main conveying line input end and each material receiving branch The lane-changing mechanism of the road conveying selects the material input line with incoming materials to conduct and receive the materials;

[0053] In the material integration and distribution step, each material receiving branch of the material distribution section merges the materials received from the material input line into the main conveying line through their respective interfaces with the main conveying line, and the materials do no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com