Creel following system

A creel and ground rail technology, applied in the field of following systems, can solve the problems of high cost and poor driving force of the creel following system, and achieve the effects of avoiding friction and adhesion, reducing wear and short yarn paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

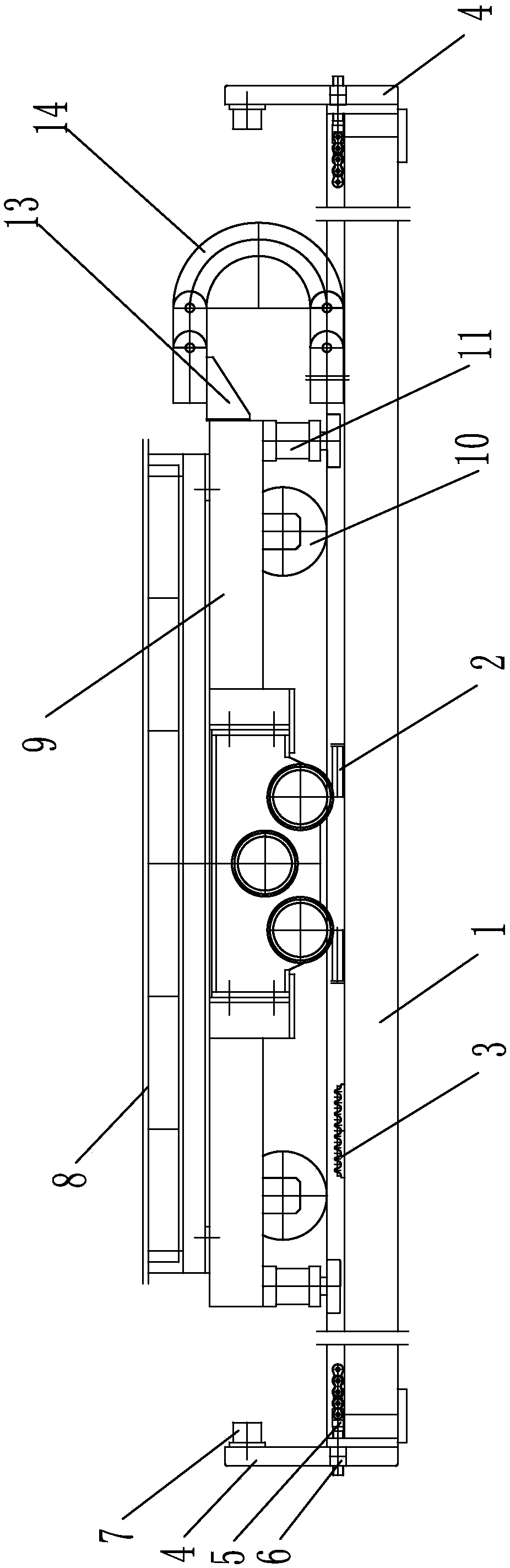

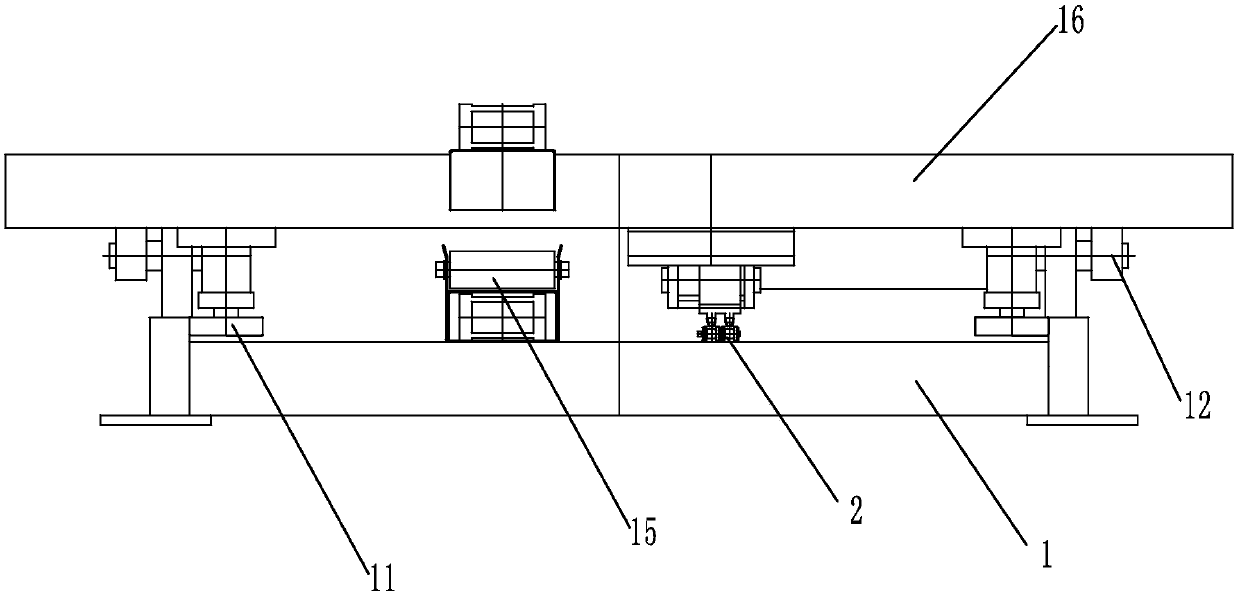

[0029] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a creel following system of this embodiment, which includes a floor rail assembly, a traveling mechanism and a driving mechanism, the floor rail assembly is installed horizontally, the traveling mechanism directly rides on the floor rail assembly, and the driving mechanism is installed on the traveling mechanism , and the driving mechanism drives the traveling mechanism to move on the ground rail assembly, and the creel 8 is installed on the traveling mechanism.

specific Embodiment approach 2

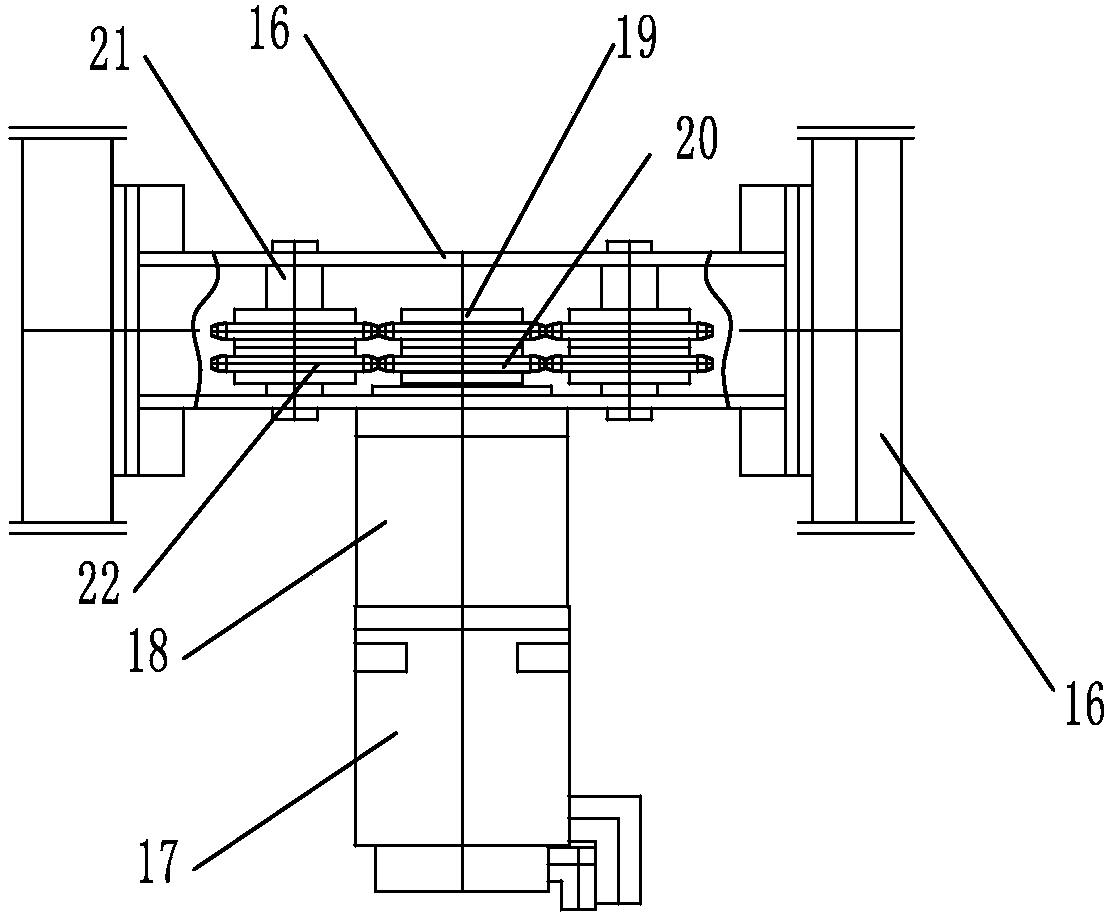

[0030] Specific implementation mode two: combination Figure 1 to Figure 3 Describe this embodiment, the ground rail assembly of this embodiment includes a ground rail 1 and a stationary chain 2, the ground rail 1 is laid horizontally, and the stationary chain 2 is installed on the upper end surface of the ground rail 1 along the length direction of the ground rail 1. In this way, the stationary chain 2 does not move on the ground rail 1 after it is installed on the ground rail 1. The driving mechanism is driven by the drive sprocket 20 to run on the ground rail 1, which is cheap and easy to implement. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation mode three: combination figure 1 Referring to this embodiment, the floor rail assembly of this embodiment further includes a plurality of chain reinforcement bars 3 installed on the upper surface of the floor rail 1 , and the chain reinforcement bars 3 engage with the stationary chain 2 . Such arrangement can effectively ensure that the driving sprocket 20 in motion can mesh with the stationary chain 2 from time to time, preventing the derailment of the sprocket and making the operation safer and more reliable. A number of chain reinforcement bars effectively segment the entire length of the chain, shortening the effective length of the chain under load and increasing the transmission rigidity in a wide range. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com