A continuous reversing valve for one-way pipe string in layered oil production

A technology of layered oil production and reversing valve, which is applied in the fields of fluid production, earthwork drilling, valve device of wellbore/well, etc., which can solve the problems of reducing oil production efficiency, increasing difficulty and cost, and being unable to reset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

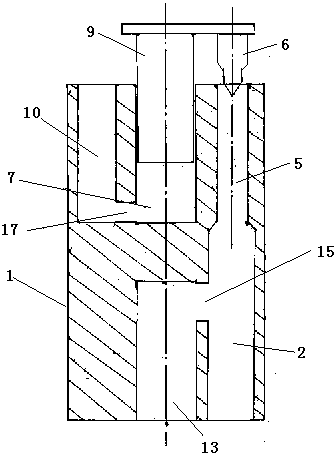

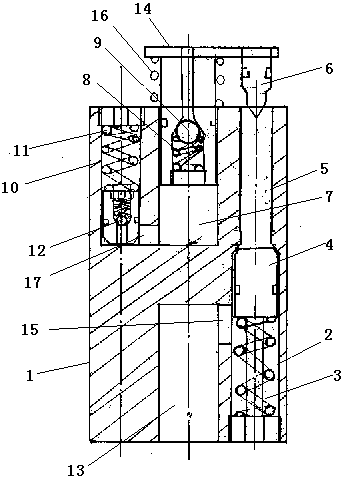

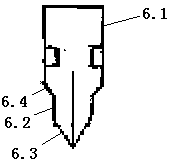

[0023] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0024] The one-way pipe string continuous reversing valve for stratified oil production mentioned in the present invention has the technical scheme that it includes a main body 1, a start-up cavity 2, a pressure relief valve 4, a pressure-pressing cavity 5, a start-up valve 6, a closing cavity 7, a closing cavity 7, and a closing cavity 7. The valve 9, the balance chamber 10, the balance valve 12, the pressure relief chamber 13 and the fixing plate 14 are provided with a start chamber 2 at the lower part of one side of the body 1, a pressure relief valve 4 is arranged in the start chamber 2, and a pressure relief valve 4 is provided in the start chamber 2. A first spring 3 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com