A Method of Correcting the Natural Frequency of Aeroengine Fan Blades

A technology of aero-engines and fan blades, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc. It can solve the problems of difficult frequency difference of blades and failure to meet the frequency matching requirements, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

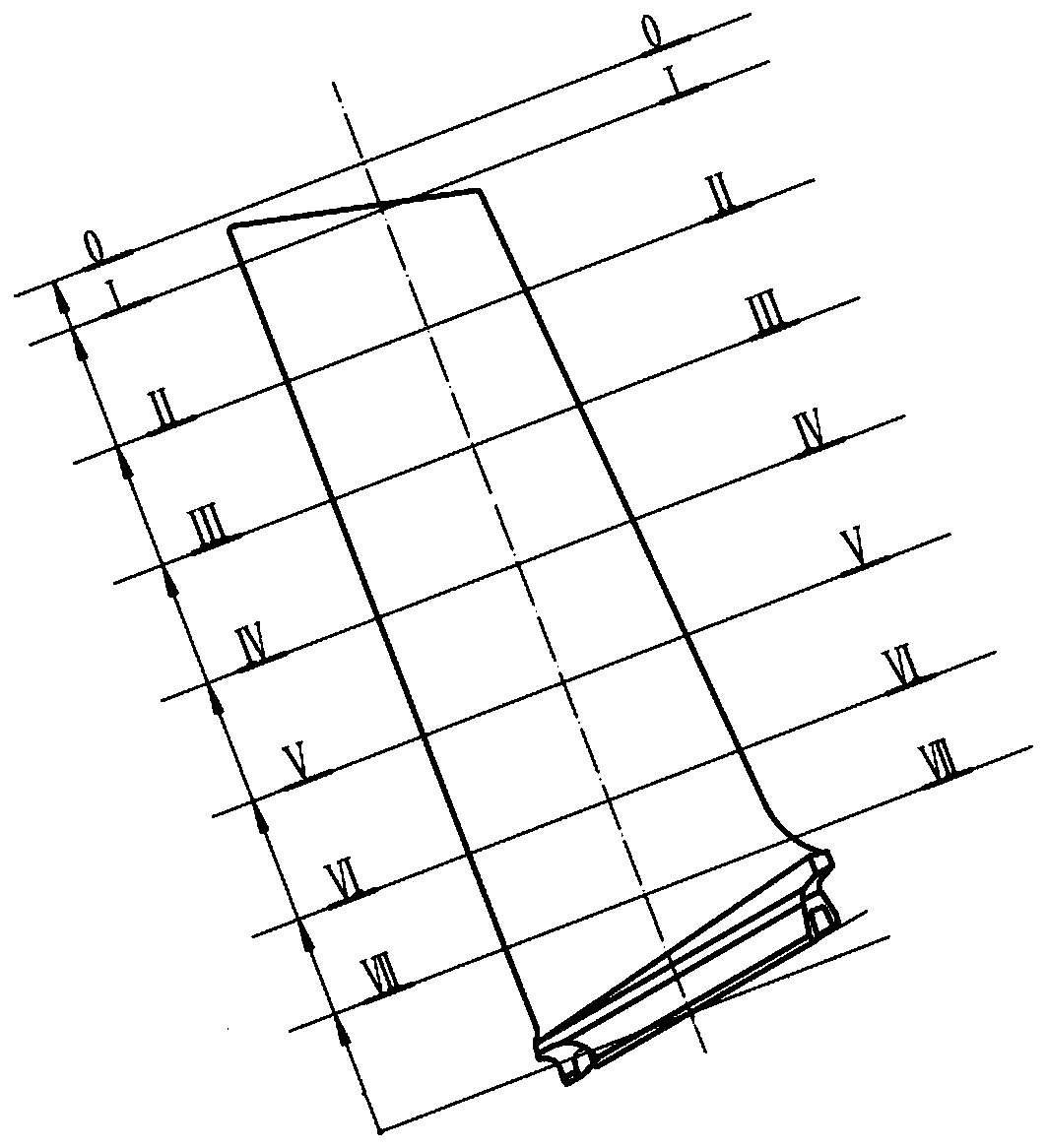

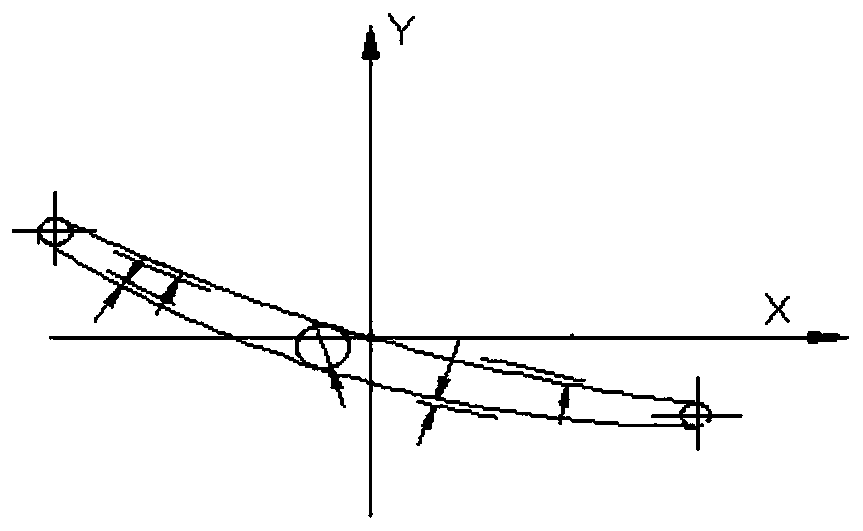

[0022] The method for correcting the natural frequency of the fan blade of an aero-engine has the following steps:

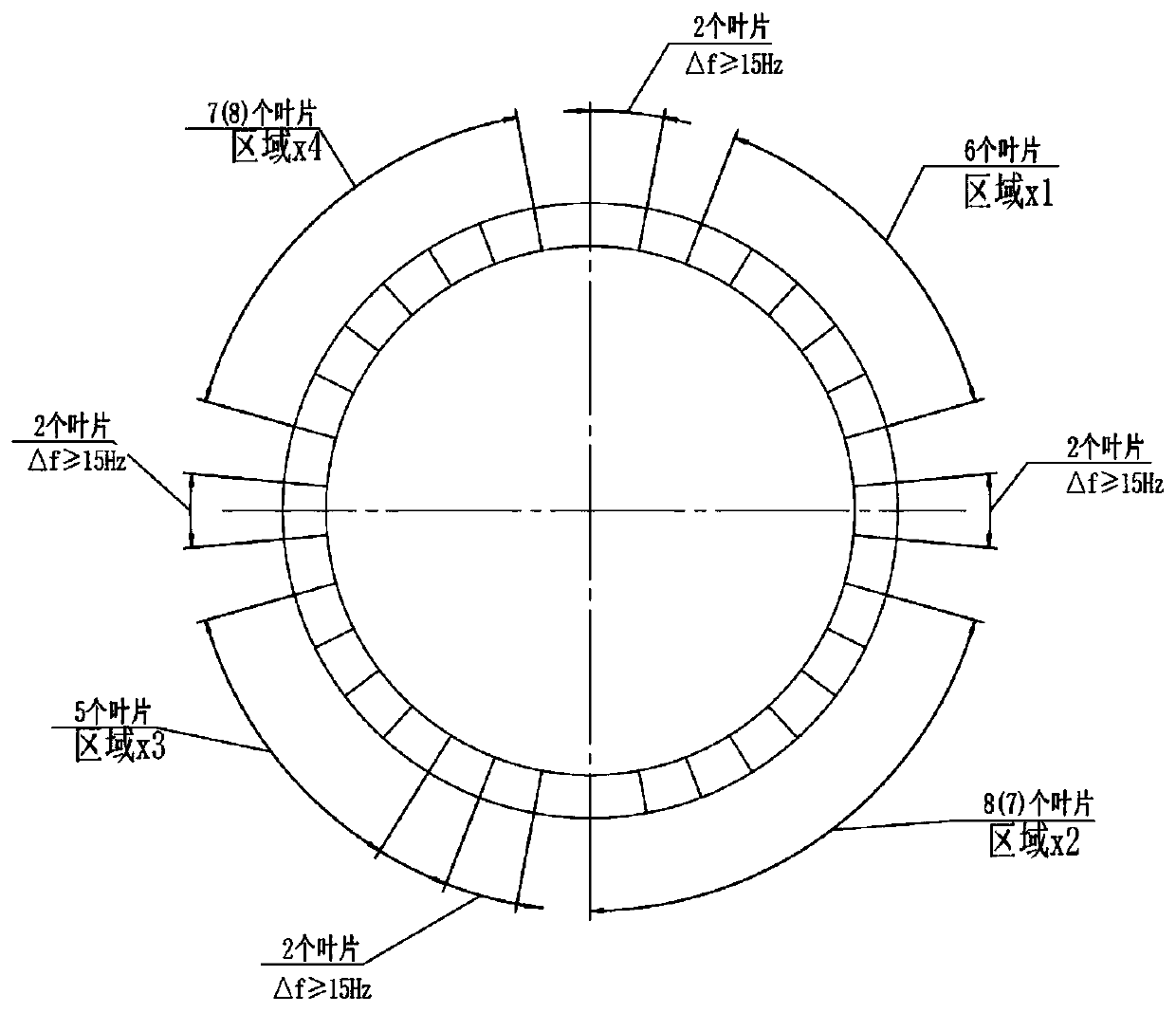

[0023] (1) Determination of frequency distribution requirements for the entire blade of the fan rotor

[0024] The frequency arrangement of fan rotor blades has a great relationship with the vibration of the engine, and fatigue cracks due to vibration are one of the common faults of the blades. Therefore, the design drawings put forward the following requirements for the frequency distribution of the entire blade of the fan rotor: the arrangement of the entire blade; the frequency difference between adjacent blades; the arrangement position of pairs of blades with different frequency differences; the maximum frequency difference of the entire blade, etc. . The fan rotor blades of an engine are made of titanium alloy TC6, the part numbers are SA1 and SA2, and there are 17 pieces for a single unit, totaling 34 pieces. The profile requirements of the fan rotor bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com