Parallel mechanism multi-objective optimization design method considering parameter nondeterminacy

A technology of parameter uncertainty and multi-objective optimization, applied in design optimization/simulation, calculation, electrical digital data processing, etc., can solve problems such as design parameter uncertainty, complex topology, lack of shortened optimization time, etc., to achieve faster The effect of mechanism optimization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

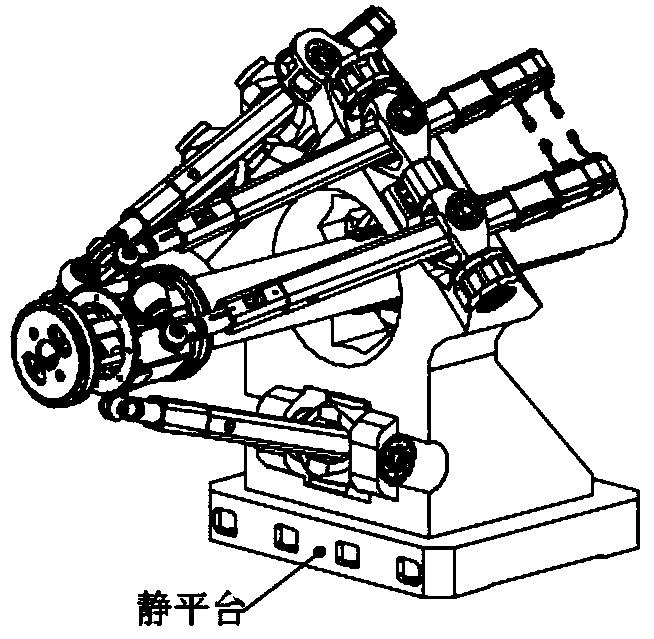

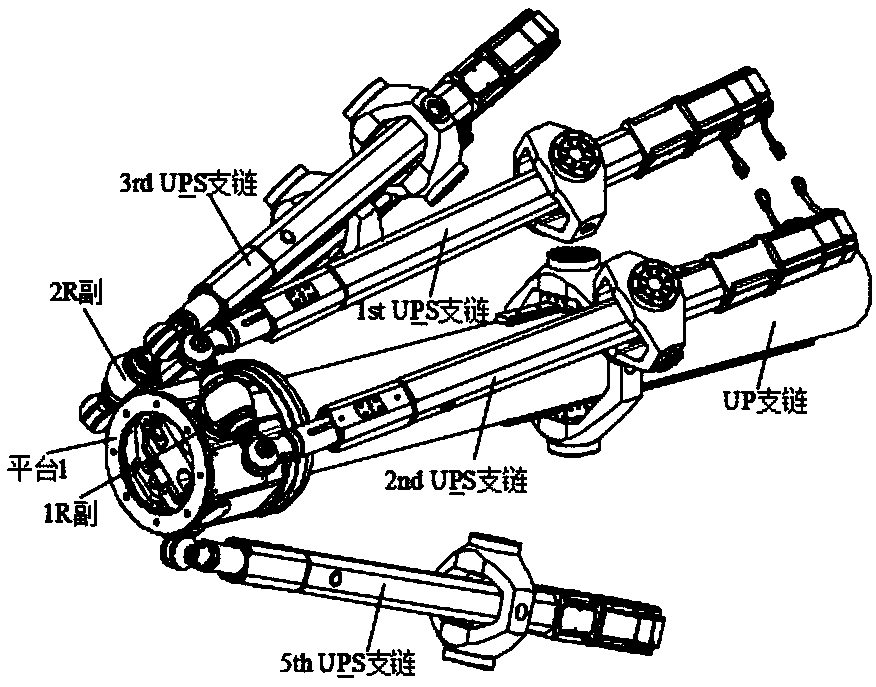

[0106] Figure 2 to Figure 5 A schematic diagram of the virtual prototype of the T5 parallel mechanism is shown.

[0107] step one,

[0108] (a) According to the working space of the T5 parallel mechanism, the multi-objective optimization design considering the uncertainty of the section parameters is carried out. The range of design variables is shown in Table 1.

[0109] Table 1 Design parameter value range

[0110]

[0111] Constraints include geometric and performance constraints of T5 parallel mechanism. Among them, the geometric constraints are set as: the wall thickness of the UPS active branch chain sleeve and telescopic rod in substructure I, the wall thickness of UP passive branch chain is not less than 4mm, and there is no interference in substructure II. Combined with the actual engineering requirements, the performance constraint is set as the isotropic linear stiffness of the T5 parallel mechanism (k lx 、k ly 、k lz ) and the angular stiffness around z (k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com