New maize germ extraction technology capable of improving purity of germs

A new technology, corn technology, applied in the agricultural field, can solve the problems of increased operating costs, less investment, and low processing energy consumption, and achieve the effects of reduced operating costs, reduced investment, and reduced material volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

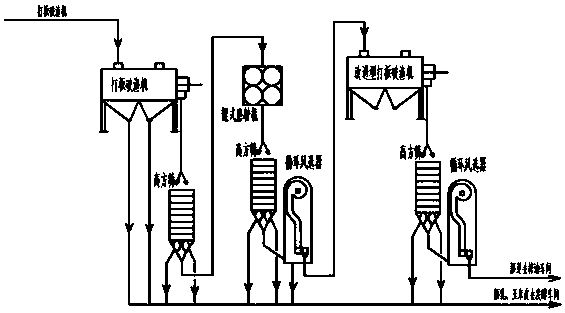

Image

Examples

example 1

[0039] 24 sets of plate-type slag breakers + 6 primary square sieves + 12 roller mills + 4 secondary high-square sieves + 4 circulating air separators + 4 improved plate-type slag breakers + 2 sets Three high square sieves + 2 circulating wind separators. The germ extraction rate reaches 65%, and the germ purity reaches 68%.

example 2

[0041] 24 sets of plate type slag breakers + 6 sets of primary square sieves + 12 sets of roller mills + 4 sets of secondary high square sieves + 4 sets of circulating wind separators + 4 sets of traditional plate type slag breakers + 2 sets of three times High square sieve + 2 circulating wind separators. The germ extraction rate reaches 63%, and the germ purity reaches 65%.

[0042] The invention overcomes the disadvantages of low purity of corn germ brought about by the traditional corn degerming process: plate-type slag breaker + vibrating sieve + roller mill + high square sieve + winnowing classifier, and can be used without significantly increasing investment. Higher purity corn germ can be obtained under the premise. At the same time, because of the close combination of crushing and separation, the amount of materials is gradually reduced, the follow-up equipment is gradually reduced, the investment is reduced, and the operating cost is reduced.

[0043] Plate type bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com