A kind of continuous preparation method of isosorbide by sorbitol

A technology of isosorbide and sorbitol, which is applied in the field of continuous preparation of isosorbide, can solve the problems of low utilization rate of raw materials, difficulty in product purification and separation, and difficult guarantee of product quality, and achieve good heat transfer effect and fast reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

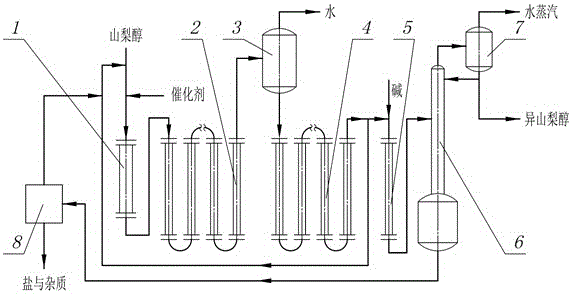

Embodiment 1

[0033] The continuous isosorbide preparation device given in Example 1 includes a raw material premixing device 1, a primary dehydration reactor 2, an intermediate dehydration device 3, a secondary dehydration reactor 4, a neutralization deacidification reactor 5, and a refined ) Distillation tower 6, isosorbide condenser 7, desalination and impurity device 8, equipment connecting pipelines, control instruments and accessories, etc. The raw material premixing device 1, the first-level dehydration reactor 2, the second-level dehydration reactor 4, and the neutralization deacidification reactor 5 are tubular equipment with external jackets and chemical fillers; the intermediate dehydration device 3 is set in one Between the second-stage dehydration reactor 2 and the second-stage dehydration reactor 4. The raw materials enter the raw material premixing device 1 in proportion and then enter the primary dehydration reactor 2 and then enter the intermediate dehydration device 3 after...

Embodiment 2

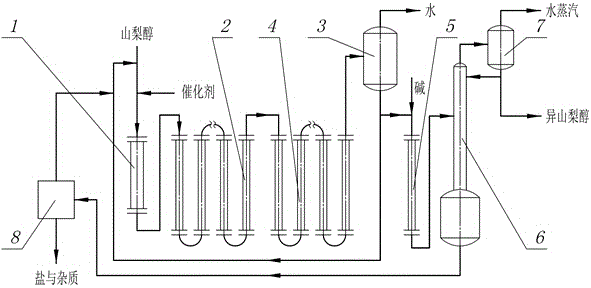

[0035] Embodiment 2 is basically the same as Embodiment 1, except that the intermediate dehydration device 3 is arranged after the secondary dehydration reactor 4, and the primary dehydration reactor 2 and the secondary dehydration reactor 4 are used in series. Example 2 such as figure 2 Shown.

Embodiment 3

[0037] Example 3 is basically the same as Example 1, except that all the materials from the secondary dehydration reactor 4 enter the neutralization deacidification reactor 5, and no unconverted raw materials (sorbitol and anhydrous sorbitol) are recycled back to the system to participate again. Operation of dehydration reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com